Commissioning

6.2 Checklists for commissioning

1FK7 G2 synchronous motors

Operating Instructions, 05/2021, A5E50907562B AA

101

Have all fastening screws, fastening elements, and electrical connections been tight-

ened with the prescribed torques and properly attached?

Do the operating conditions correspond to the data specified on the rating plate?

Do the output elements have the correct setting conditions according to type?

Examples:

• Have the couplings been aligned and balanced?

• Has the belt drive tension been correctly adjusted?

• Have the gear tooth flank and gear tooth tip play as well as radial play been correct-

ly adjusted for geared outputs?

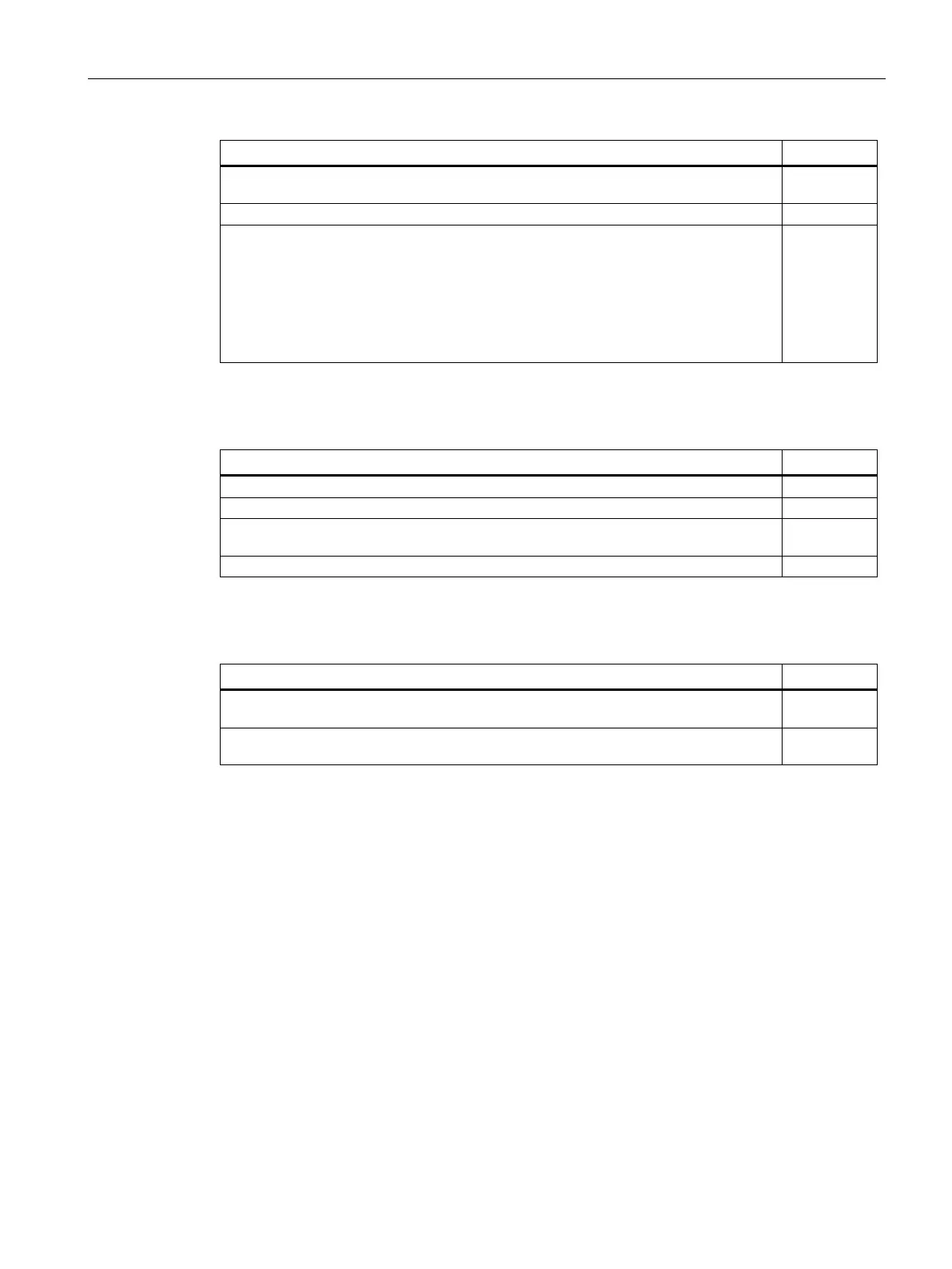

Table 6- 3 Checklist (3) - checks regarding the electrical system

Has the motor been connected so that it rotates in the specified direction?

Have the minimum insulation resistance values been maintained?

Have the grounding and equipotential bonding connections been correctly estab-

lished?

Is the specified limit speed nmax maintained during the operation on the converter?

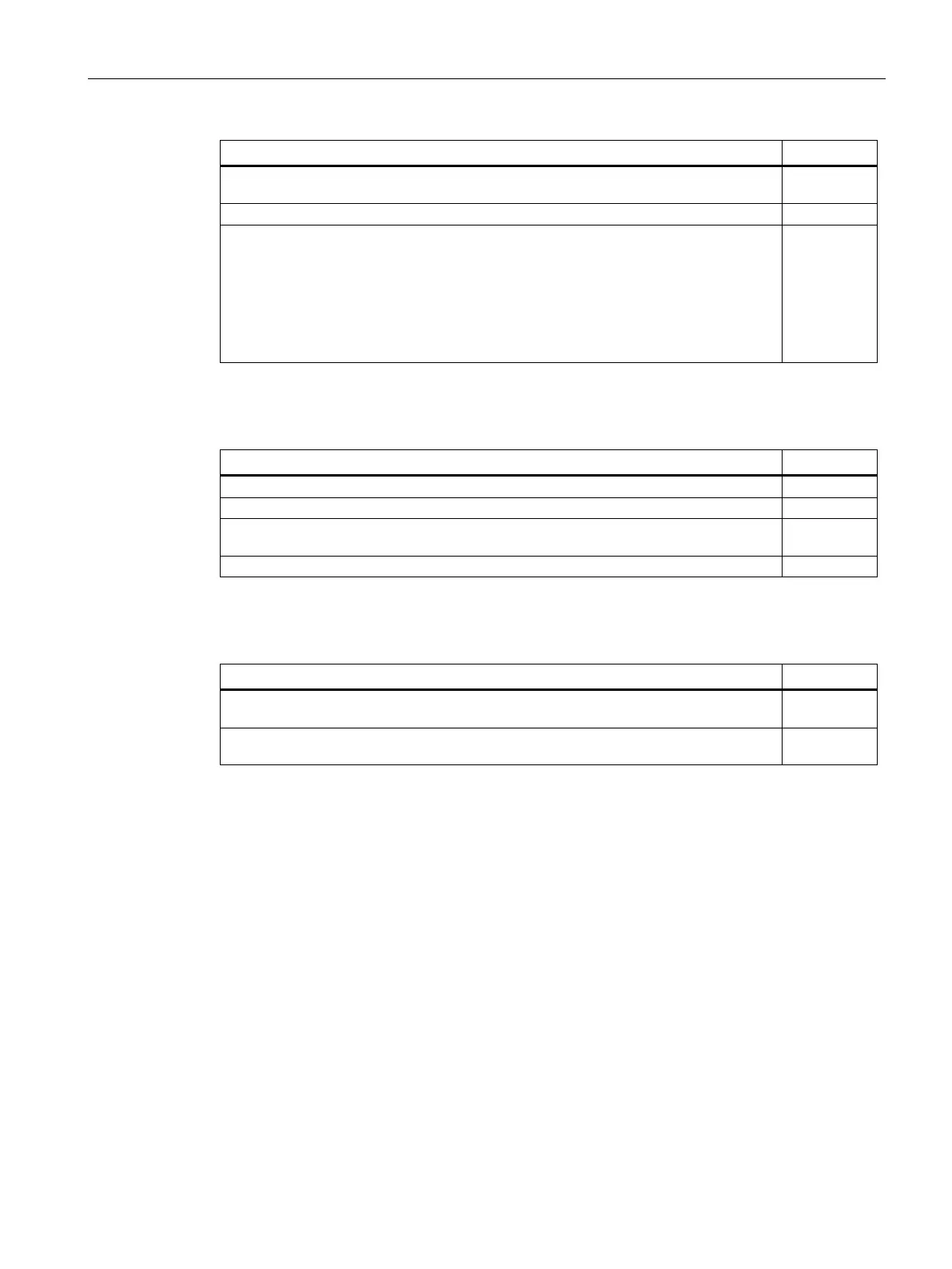

Table 6- 4 Checklist (4) - Monitoring equipment checks

Has it been ensured that speeds higher than the maximum speed n

max

Have all supplementary motor monitoring devices been correctly connected and are

they working properly?

Loading...

Loading...