Mounting

4.3 Mounting instructions

1FK7 G2 synchronous motors

56 Operating Instructions, 05/2021, A5E50907562B AA

4.3 Mounting instructions

Damage to the motor due to runout on the shaft extension

Runout and thrust on the shaft extension of the motor can damage the motor.

• Mount the motor without runout and thrust on the shaft extension.

Observe the technical data on the rating plate on the motor enclosure.

• Observe the data on the rating plate, as well as the warning and information plates on the

motor.

• Check the permissible ambient conditions (e.g. temperature, installation altitude) at the

installation location.

Their use is prohibited in hazardous zones.

• Thoroughly clean the shaft extension of corrosion protection. Use commercially available

solvents.

• Ensure sufficient dissipation of heat. See Chapter "Mounting conditions (Page 58)"

• If the motor is installed vertically with the end of the shaft facing up, ensure that no liquid

can enter the upper bearing.

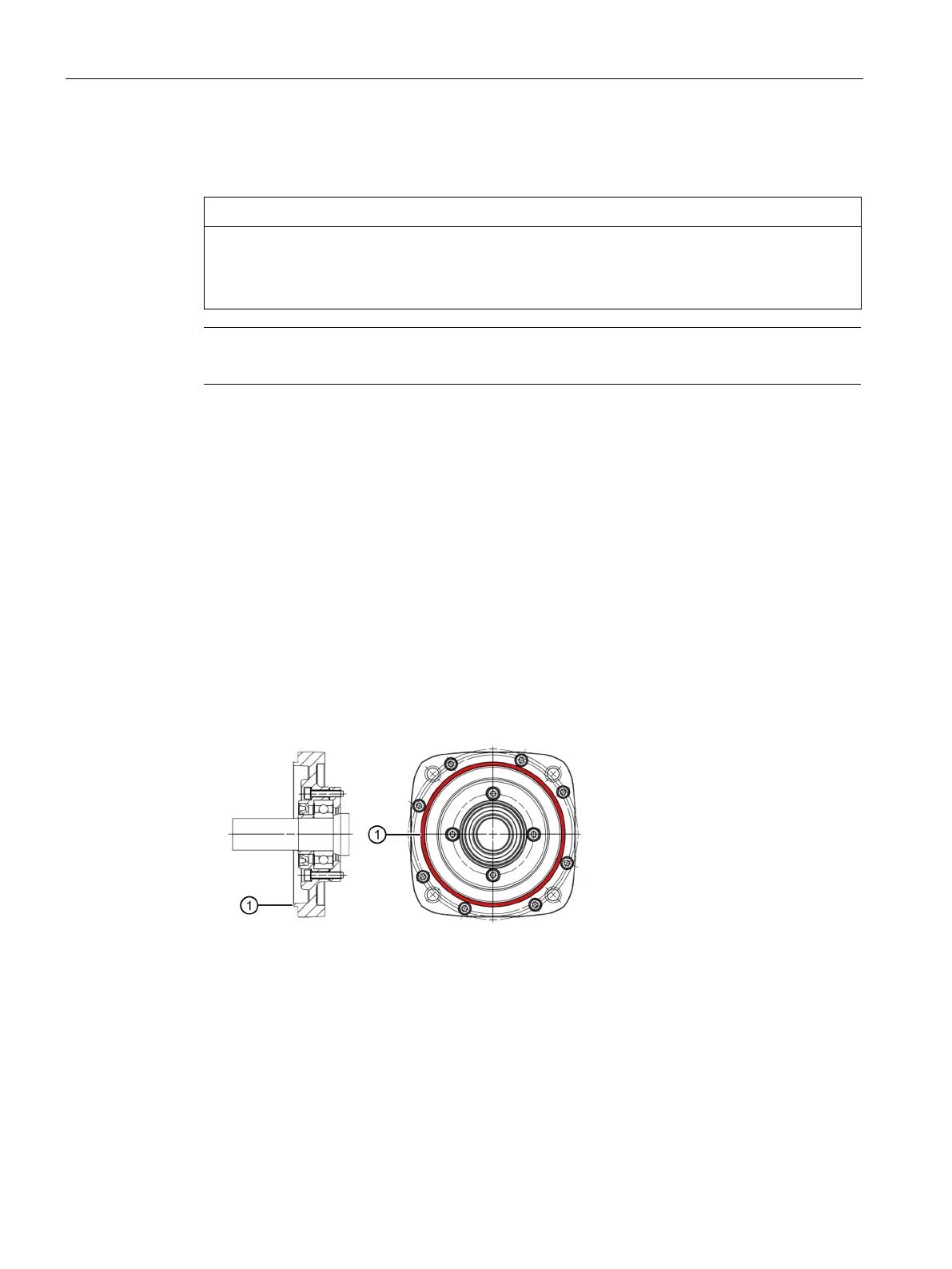

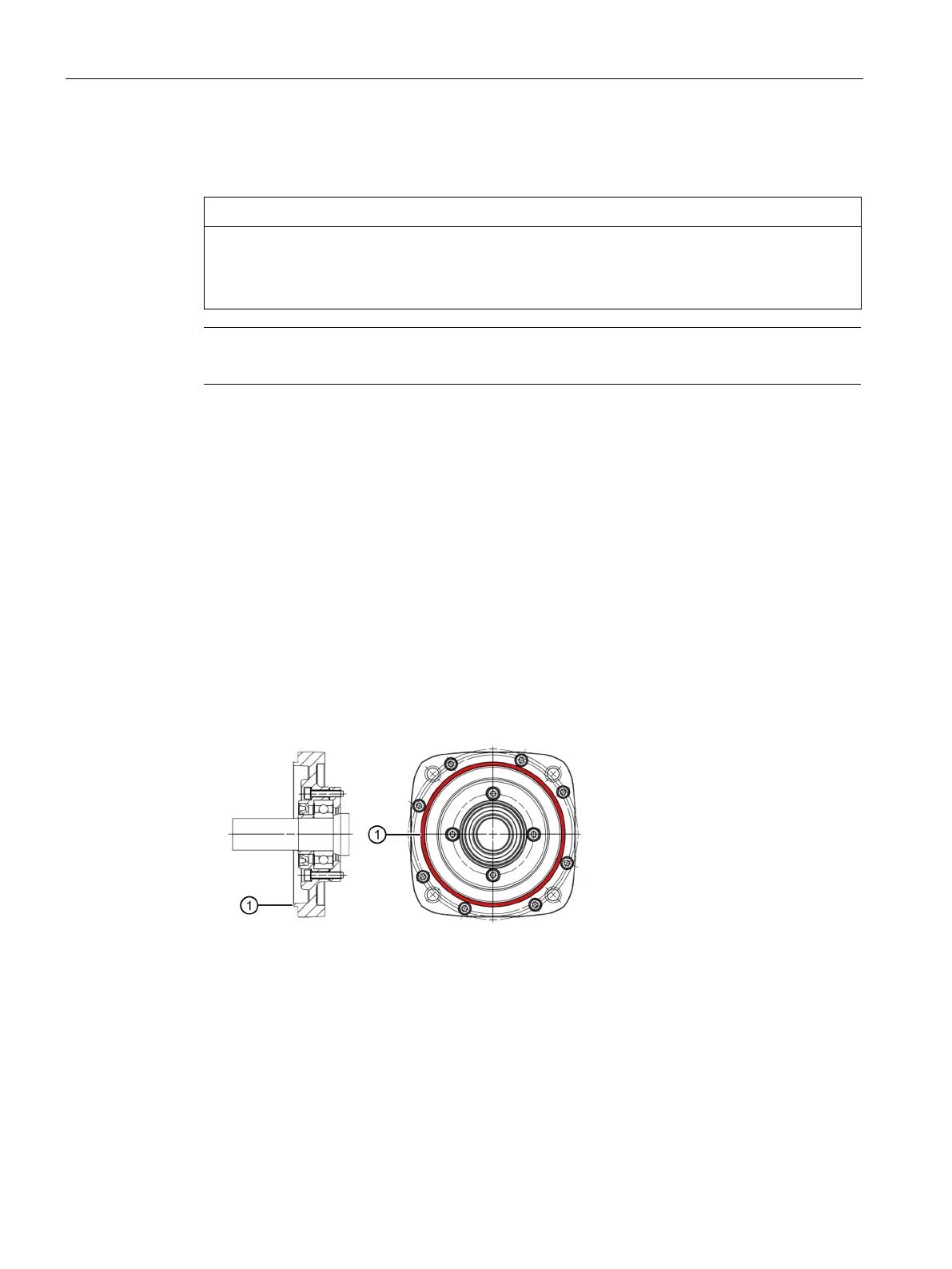

• If fluid media come into contact with the DE flange, a special flange seal is required.

The motor is sealed via the machined flat contact surface of the centering edge on the DE

flange, e.g. with an O ring. The sealing is on the circumference. Sealing at the flange

contact surface of the motor is not envisaged.

Figure 4-1 Position of the sealing surface on the face of the centering edge

• Ensure that the flange is in even contact with the mounting surface.

• Use hexagon socket head cap screws with a property class of at least 8.8.

• When tightening the fastening bolts avoid any uneven stressing.

• Observe the tightening torques of the fastening bolts of the motor flange. See the

"Tightening torques for fastening bolts" table.

• After installation, remove the lifting eyes or tighten them.

Loading...

Loading...