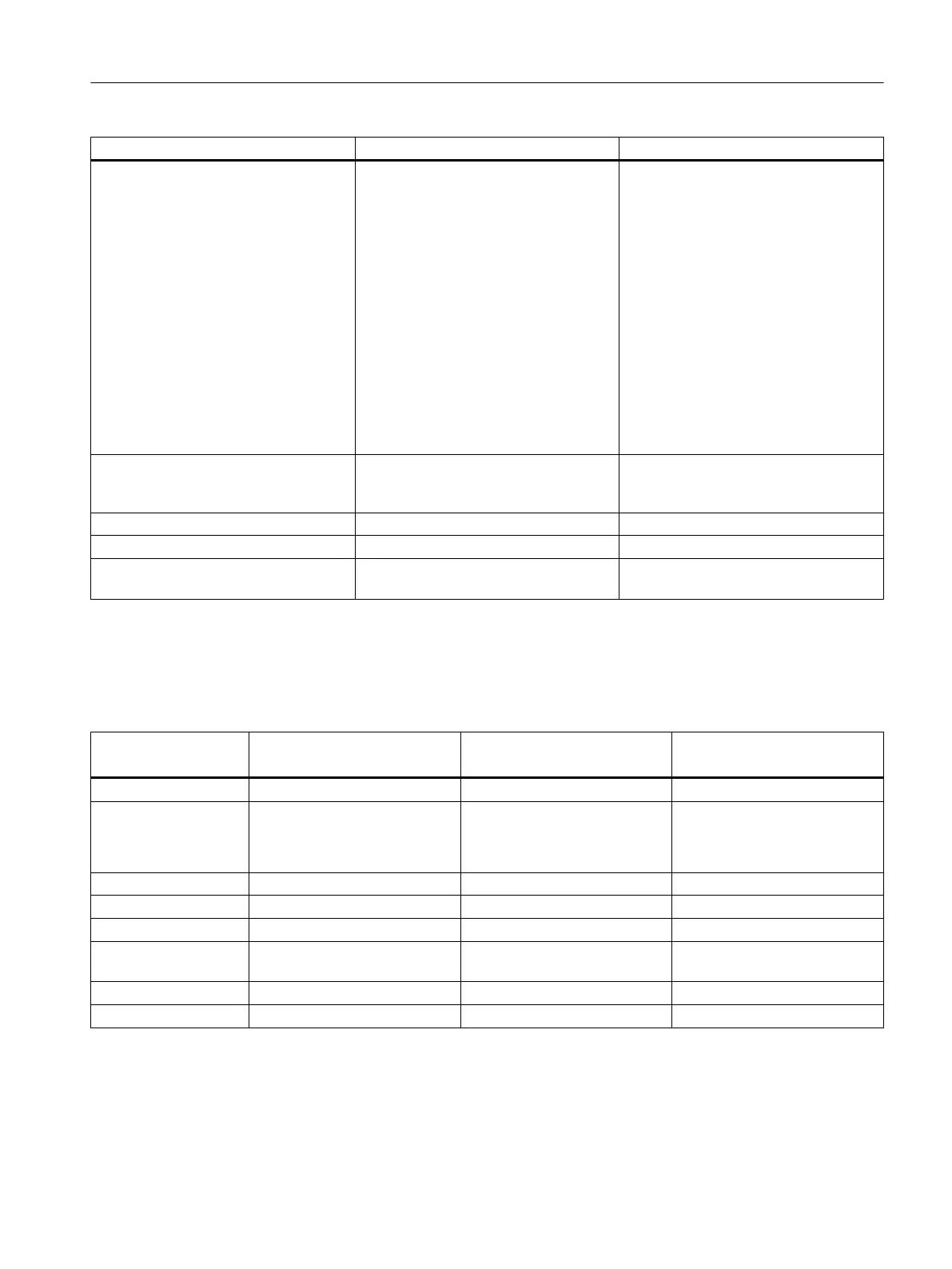

Local measuring input Global measuring input

TO measuringInput setting: Cyclical

measurement

(The measurement is activated just

once and runs cyclically until deactiva‐

ted.)

No Yes

D410, D410-2, D4x5, D4x5‑2 (terminal

X122, X132), CX32, CX32‑2, CU310,

CU310-2, CU320, CU320‑2:

The minimum interval between two

measurements is three servo cycle

clocks (max. two edges per measure‐

ment).

D4x5‑2

(terminalX142), TM17 High Fea‐

ture, ET 200SP/MP timer DIDQ:

The minimum interval between two

measurements is one servo cycle clock

(max. two edges per measurement).

TM15:

No cyclic measurement available

Use of multiple TO measuringInputs on

one axis/encoder. They can be active

concurrently

No Yes

Listening TO measuringInput No Yes

Measuring on virtual axes No Yes

Measuring on axes attached to a differ‐

ent drive unit

No Yes

SIMOTION Utilities & Applications includes, for example, a tool to estimate:

●

The time between a measurement job being initiated and it being effective in the drive.

● The minimum time between two measurement jobs.

SIMOTION Utilities & Applications is part of the scope of delivery of SIMOTION SCOUT.

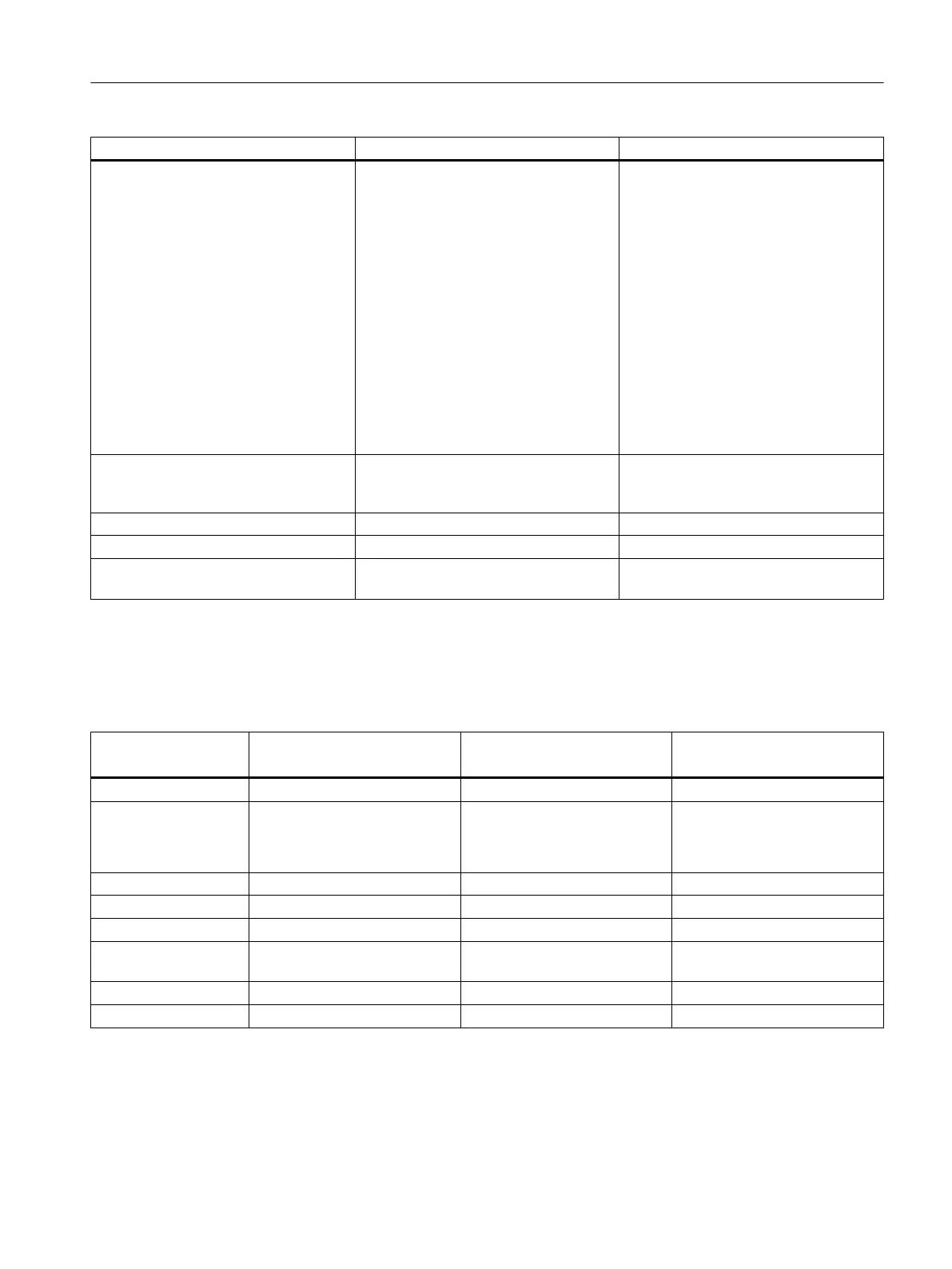

Max. number of

measuring input inputs

As local measuring input

configurable

As global measuring input

configurable

D410-2, CU310-2 8 x x

D4x5-2

●

X122/X132

● X142

● 8

● 8

● 8

● 0

● 8

● 8

CX32-2 4 x x

D410, CU310, CX32 3 x x

D4x5, CU320 6 x x

ET 200MP TM timer

DIDQ 16x24V

8 - x

TM15 24 - x

TM17 High Feature 16 - x

Configuration of drive-related I/Os (without symbolic assignment)

A.2 Local and global measuring inputs

SIMOTION D4x5-2

Commissioning and Hardware Installation Manual, 03/2018, A5E33441636B 415

Loading...

Loading...