Technical Appendix

SINUMERIK 802S base line

6-7

Start-Up

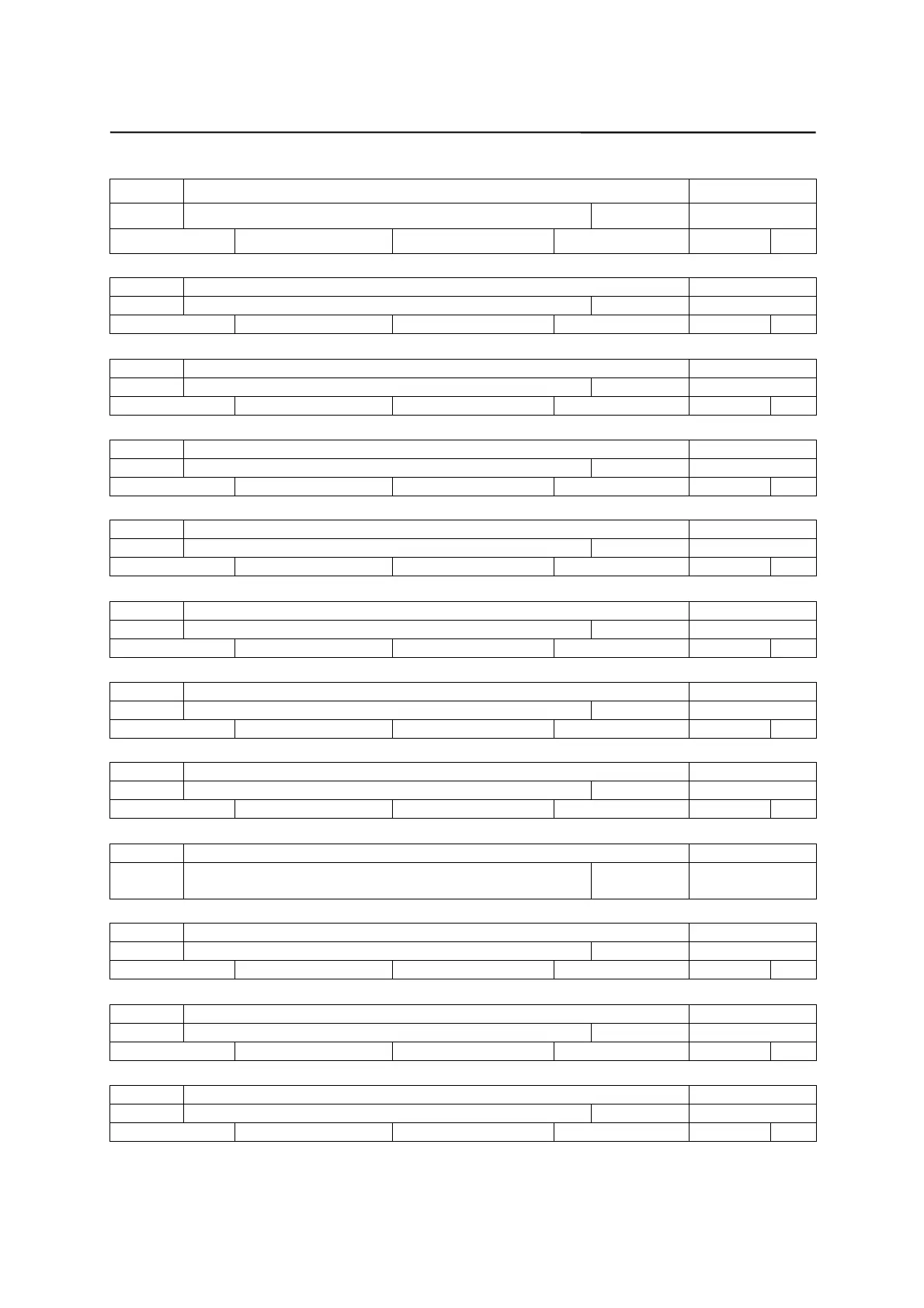

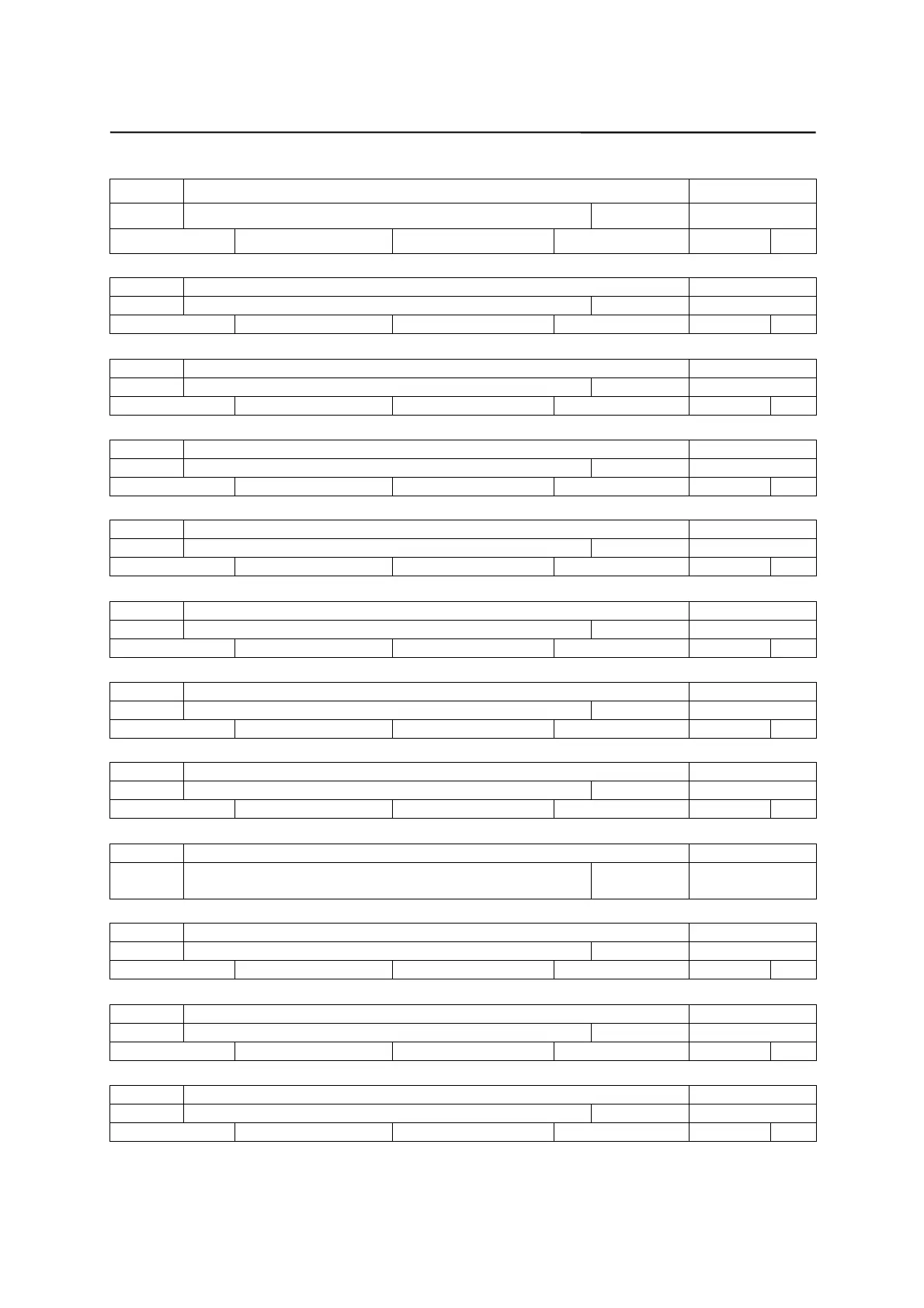

31010 ENC_GRID_POINT_DIST

mm Division period for linear scales (encoder no.) POWER ON

_always 0.01 0.0 plus DOUBLE 2/7

31020 ENC_RESOL

– Encoder markings per revolution (encoder no.) POWER ON

_always 2048 0.0 plus DWORD 2/7

31030 LEADSCREW_PITCH

mm Pitch of leadscrew POWER ON

_always 10.0 0.0 plus DOUBLE 2/7

31040 ENC_IS_DIRECT

– Encoder mounted directly to the machine (encoder no:) POWER ON

_always 0 *** ***

BOOLEAN

2/7

31050 DRIVE_AX_RATIO_DENOM

– Denominator load gearbox (control parameter no.): 0...5 POWER ON

_always 1, 1, 1, 1, 1, 1 1 2147000000 DWORD 2/7

31060 DRIVE_AX_RATIO_NUMERA

– Numerator load gearbox (control parameter set no.): 0...5 POWER ON

_always 1, 1, 1, 1, 1, 1 1 2147000000 DWORD 2/7

31070 DRIVE_ENC_RATIO_DENOM

– Denominator resolver gearbox (encoder no.) POWER ON

_always 1 1 2147000000 DWORD 2/7

31080 DRIVE_ENC_RATIO_NUMERA

– Numerator resolver gearbox (encoder no.) POWER ON

_always 1 1 2147000000 DWORD 2/7

31090 JOG_INCR_WEIGHT

mm,

degrees

Evaluation of an increment with INC/handwheel RESET

31100 BERO_CYCLE

– Steps for monitoring rotation POWER ON

2000 10 10000000 DWORD 2/7

31110 BERO_EDGE_TOL

– Step tolerance for monitoring rotation POWER ON

50 10 10000000 DWORD 2/7

31350 FREQ_STEP_LIMIT

– Stepping rate at maximum velocity NEW CONF

Hz 250000 0.1 4000000 DOUBLE 2/7

Loading...

Loading...