Start-Up

4-18

SINUMERIK 802S base line

Start-Up

-Y

+Y

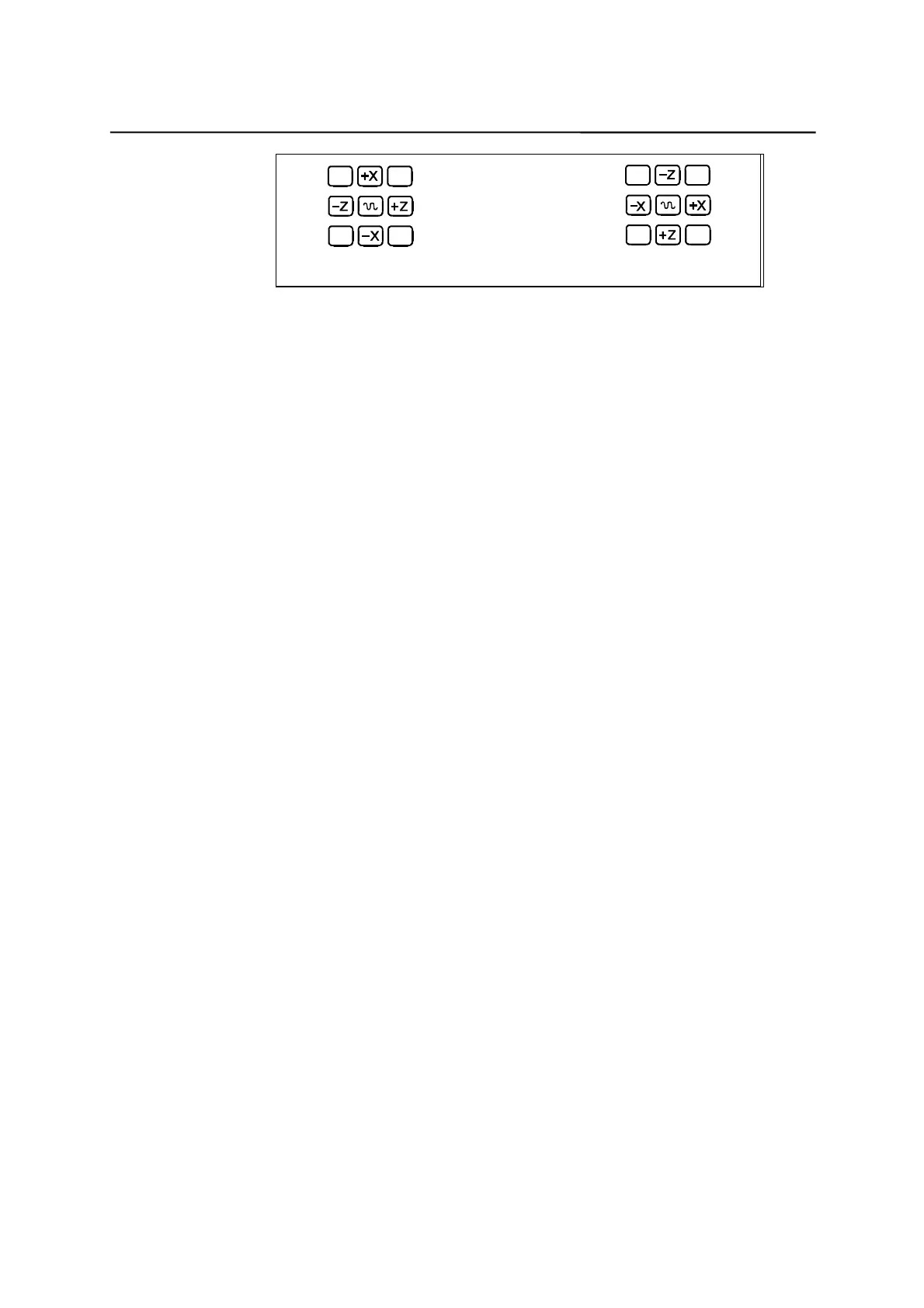

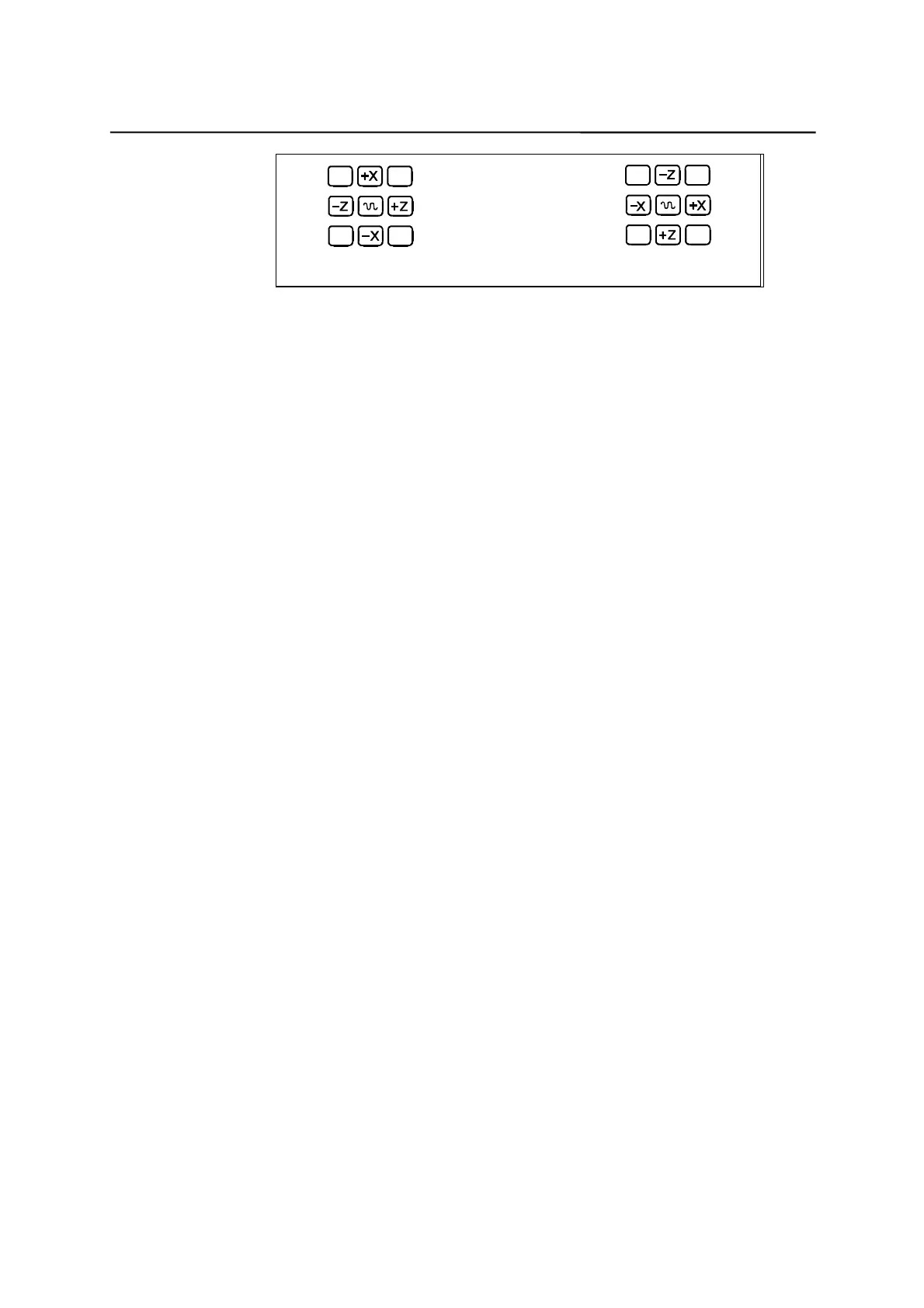

horizonal turning machine vertical milling machine

Fig. 4-4 Examples for the assignment of the axis keyboard

4.3.5 PLC programming

The PLC user program is created using the PLC 802 Programming Tool.

The Documentation “S7-200 Automation System, System Manual” describes

how this tool is operated for S7-200. The PLC 802 Programming Tool is to be

understood as a subset of this Documentation.

Compared with the S7-200 MicroWin basic system, please note the following:

z

The PLC 802 Programming Tool is delievered in the English language

version.

z

The user program can only be programmed using ladder diagram.

z

Only a subset of the S7-200 programming language is supported.

z

The compilation of the user program is carried out either offline on a

programming device (PG)PC or semi-automatically when downloading

into the control system.

z

The project can be loaded into the control system (download).

z

It is also possible to load the project from the control system (upload).

z

Direct data addressing is not possible; therefore, no programming errors

will result during the operation.

z

The data/process information must be managed by the user in

accordance with the particular type.

Example:

Information 1 T value DWord memory size (32-bit)

Information 2 Override Byte memory size (8-bit)

User data

Byte 0 DWord (Information 1)

Byte 4 Byte (Information 2)

The user is not allowed to access both of these data at the same time;

otherwise, the relevant data access rules must be observed.

z

Furthermore, the data direction in the memory model (alignment) and the

data type must be observed for all data.

Example:

Flag bit MB0.1,MB3.5

Flag byte MB0,MB1,MB2

Flag word MW0,MW2,MW4

MW3, MW5 ... are not permissible

Flag double-word MD0,MD4,MD8

MD1,MD2,MD3, MD5 ... are not permissible

Loading...

Loading...