Commissioning Manual

496 01/2017

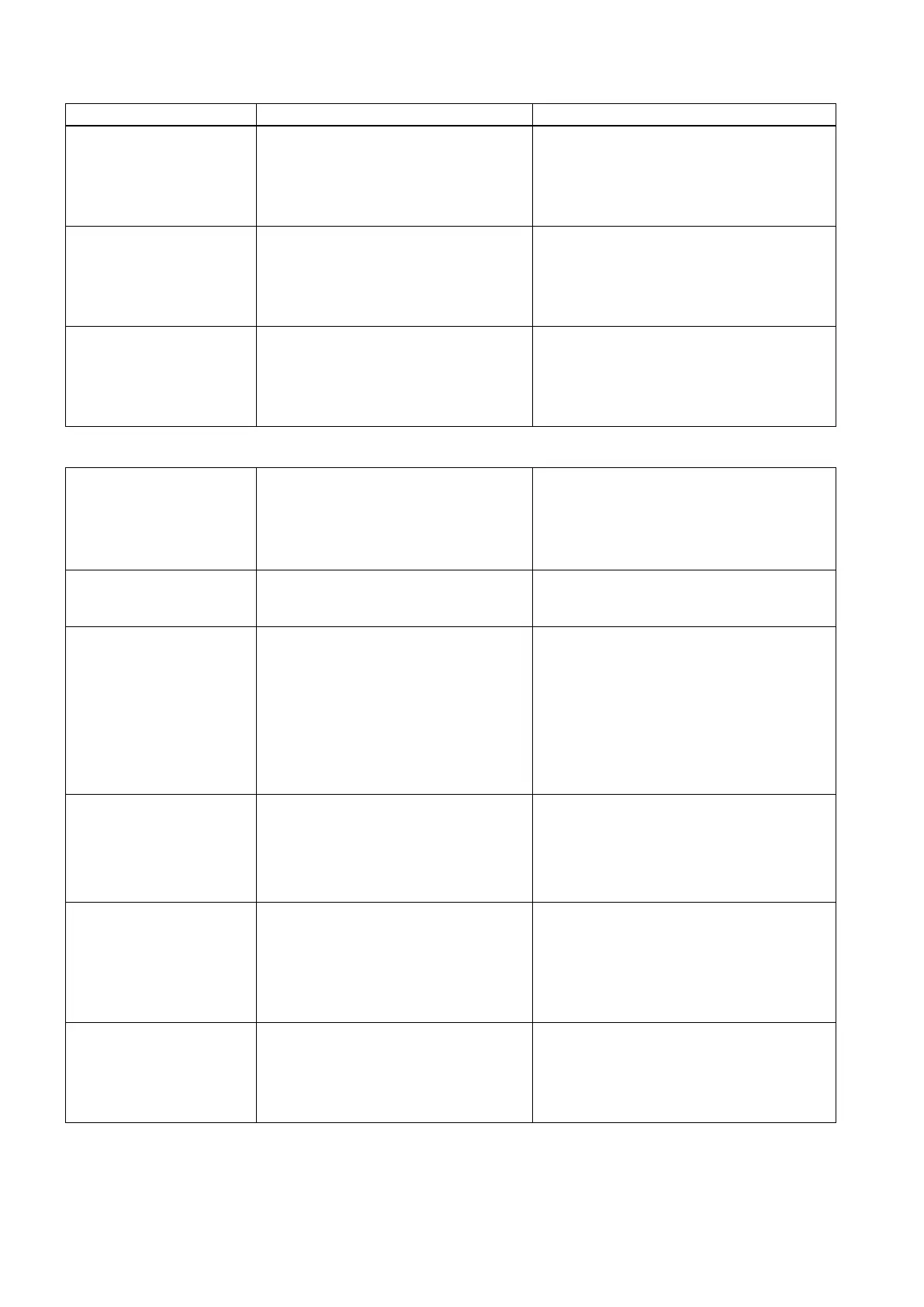

F52984: Incremental encod-

er motor not configured

Reaction: OFF1

Acknowledgement:

• Commissioning of the servo motor has

failed.

• An incremental encoder motor is con-

nected but not commissioned.

Configure the motor ID by setting the parame-

ter p29000.

F52985: Absolute encoder

motor wrong

Reaction: OFF1

Acknowledgement:

•

Motor ID is downloaded wrong during

manufacture.

• The software of the servo drive does

not support the Motor ID.

•

• Use a suitable motor.

F52987: Absolute encoder

replaced

Reaction: OFF1

Acknowledgement:

Incorrect data of the absolute encoder. Contact the Hotline.

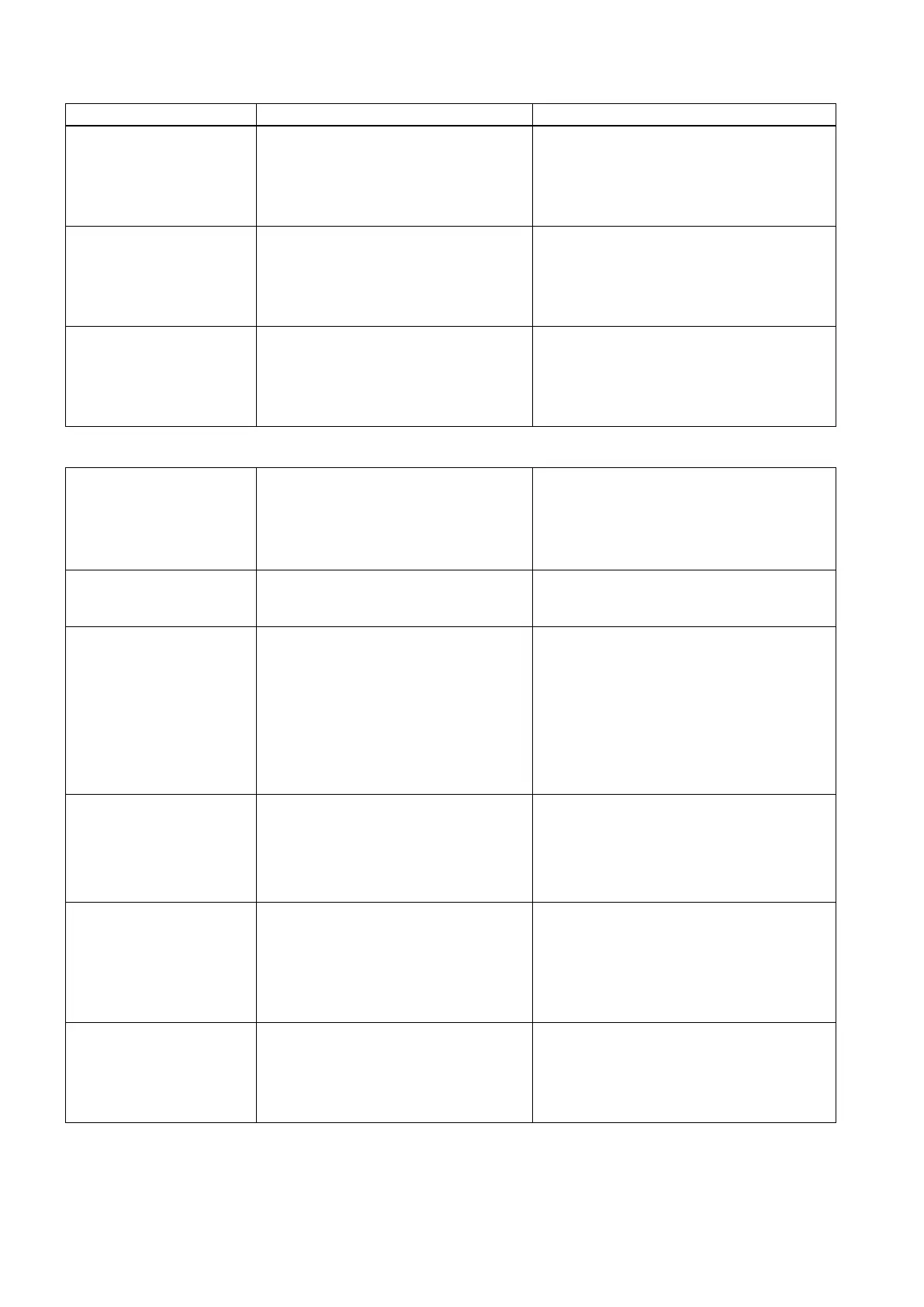

A1009: Control module over-

temperature

The temperature of the control module

(Control Unit) has exceeded the specified

limit value.

• Check the air intake for the Control Unit.

• Check the Control Unit fan.

Note:

The alarm automatically disappears after the

limit value has been undershot.

A1019: Writing to the re-

movable data medium un-

successful

The write access to the removable data

medium was unsuccessful.

Remove and check the removable data medi-

um. Then run the data backup again.

A1032: All parameters must

be saved

The parameters of an individual drive

object were saved, although there is still

no backup of all drive system parameters.

The saved object-specific parameters are

not loaded the next time that the system

powers up.

For the system to successfully power up,

all of the parameters must have been

Save all parameters.

A1045: Configuring data

invalid

An error was detected when evaluating the

parameter files saved in the non-volatile

memory. Because of this, under certain

circumstances, several of the saved pa-

rameter values were not able to be ac-

cepted.

Save the parameterization using the "SAVE"

function on the BOP. This overwrites the incor-

rect parameter files in the non-volatile memory

– and the alarm is withdrawn.

A1920: Drive Bus: Receive

setpoints after To

Output data of Drive Bus master (set-

points) received at the incorrect instant in

time within the Drive Bus clock cycle.

• Check bus configuration.

• Check parameters for clock cycle synchro-

nization (ensure To > Tdx).

Note:

• To: Time of setpoint acceptance

•

A1932: Drive Bus clock

cycle synchronization miss-

ing for DSC

There is no clock synchronization or clock

synchronous sign of life and DSC is se-

lected.

Note:

DSC: Dynamic Servo Control

Set clock synchronization across the bus con-

figuration and transfer clock synchronous sign-

of-life.

Loading...

Loading...