Cycles

2.5 Turning cycles

Turning Part 2: Programming (Siemens instructions)

Programming and Operating Manual, 05/2012, 6FC5398-5DP10-0BA0

169

The first block with a traversing motion in the current machining plane must contain a motion

command G0, G1, G2 or G3; otherwise, the cycle is canceled, and alarm 15800 "Incorrect

prerequisites for CONTPRON" is issued. This alarm is also issued if G41/42 is active. The

starting point of the contour is the first programmed position in the machining plane.

To machine the programmed contour, a cycle-internal memory is prepared which can

accommodate a certain maximum number of contour elements; how many, depends on the

contour. If a contour contains too many contour elements, the cycle is canceled, and alarm

10934 "Contour table overflow" is issued. In this case, the contour must be split over several

contour sections, and the cycle for each section must be called separately.

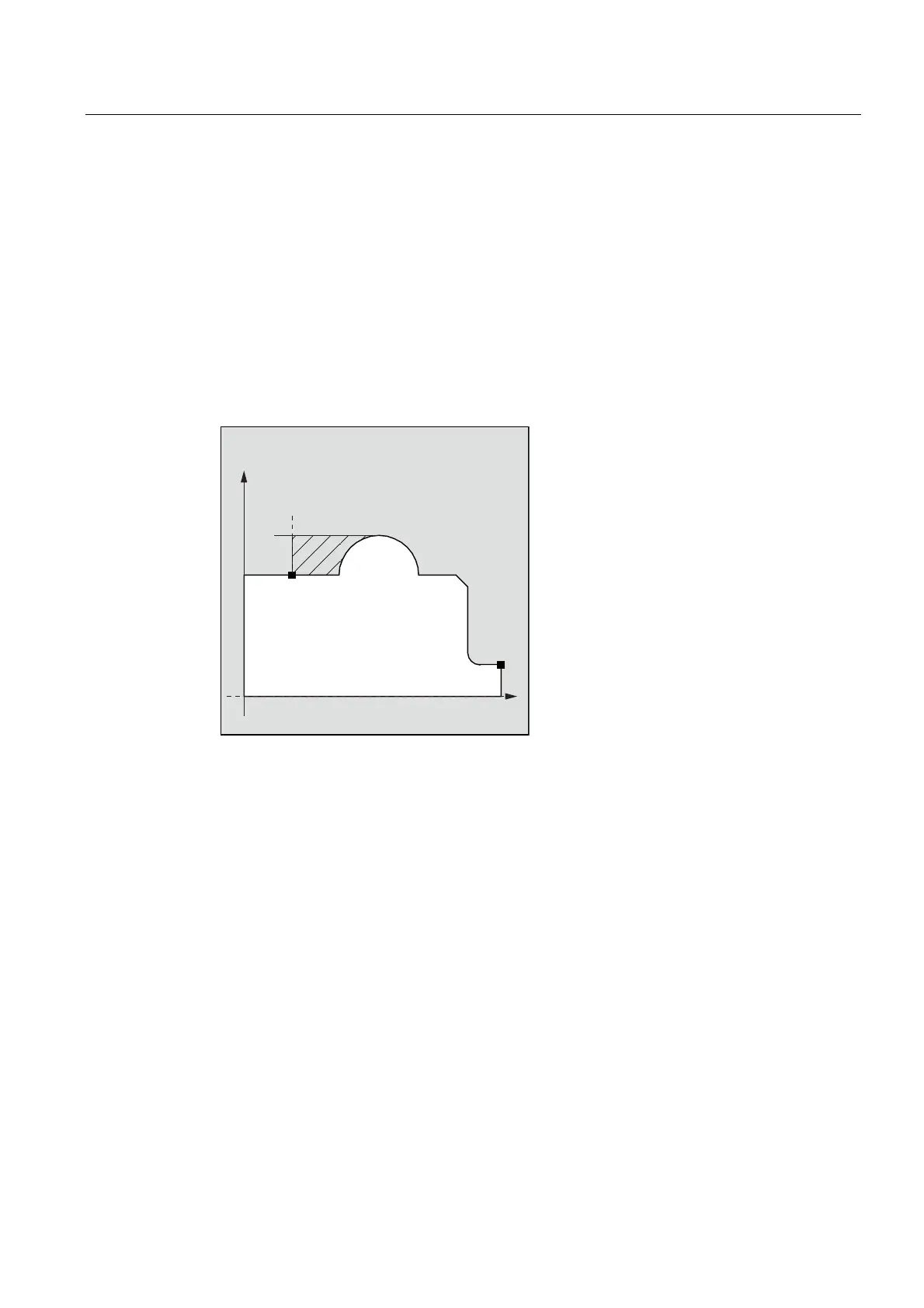

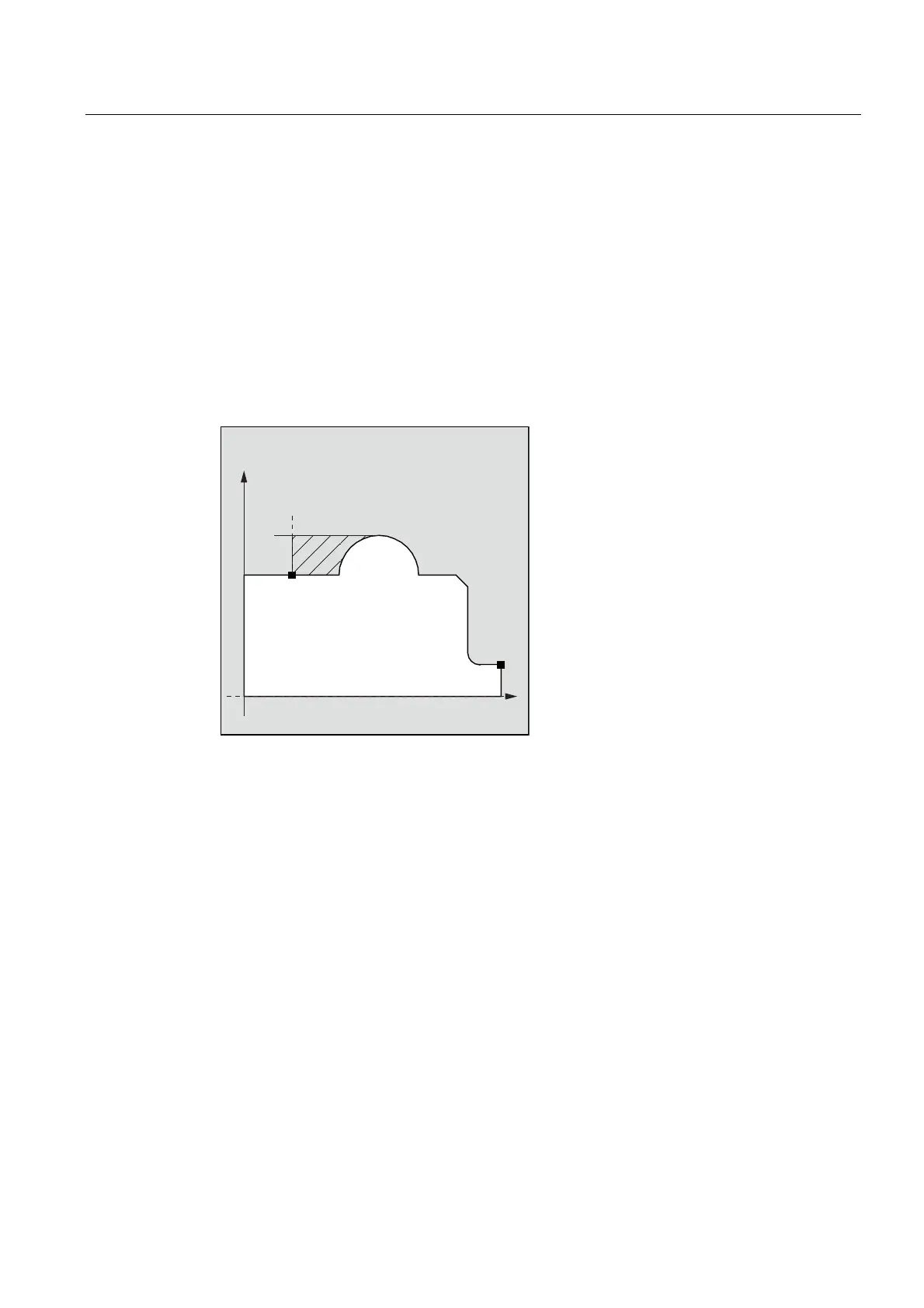

If the maximum diameter is not at the programmed end or starting point of the contour, the

cycle will automatically add an axis-parallel straight line to complete the contour maximum,

and this part is removed as the undercut.

;

=

6WDUWLQJ

SRLQW

(QGSRLQW

$GGHG

VWUDLJKWOLQH

If a tool radius compensation is programmed in the contour subroutine with G41/G42, the

cycle is canceled, and alarm 10931 "Faulty cutting contour" is issued.

contour direction

The direction in which the stock removal contour is programmed can be freely selected. In

the cycle, the machining direction is defined automatically. In complete machining, the

contour is finished in the same direction as machining was carried out when roughing.

When deciding on the machining direction, the first and the last programmed contour points

are taken into account. Therefore, both coordinates must always be programmed in the first

block of the contour subroutine.

Contour monitoring

The cycle provides contour monitoring with regard to the following:

● Clearance angle of the active tool

● Circular programming of arcs with an arc angle > 180 degrees

Loading...

Loading...