Programming principles

1.2 Positional data

Turning Part 2: Programming (Siemens instructions)

30 Programming and Operating Manual, 05/2012, 6FC5398-5DP10-0BA0

Note

A programmable offset with TRANS X... or ATRANS X... is always evaluated as radius

dimensioning. Description of this function: see the next section.

1.2.5 Programmable work offset: TRANS, ATRANS

Functionality

The programmable work offset can be used:

● for recurring shapes/arrangements in various positions on the workpiece

● when selecting a new reference point for the dimensioning

● as a stock allowance when roughing

This results in the current workpiece coordinate system. The rewritten dimensions use this

as a reference.

The offset is possible in all axes.

Note

In the X-axis, the workpiece zero should be in the turning center due to the functions of

diameter programming (DIAMON) and constant cutting speed (G96). For this reason, use no

offset or only a small offset (e.g. as allowance) in the X axis.

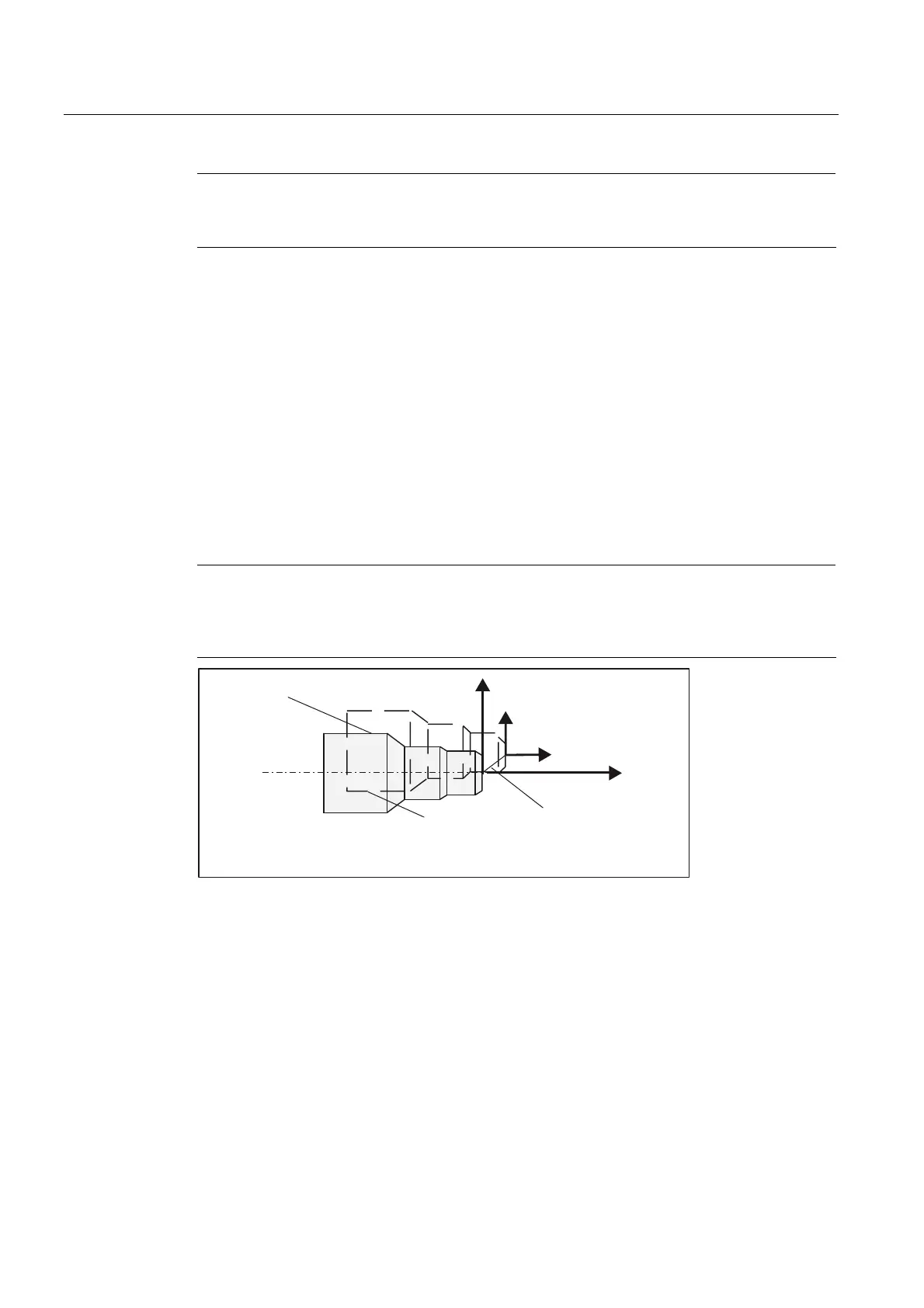

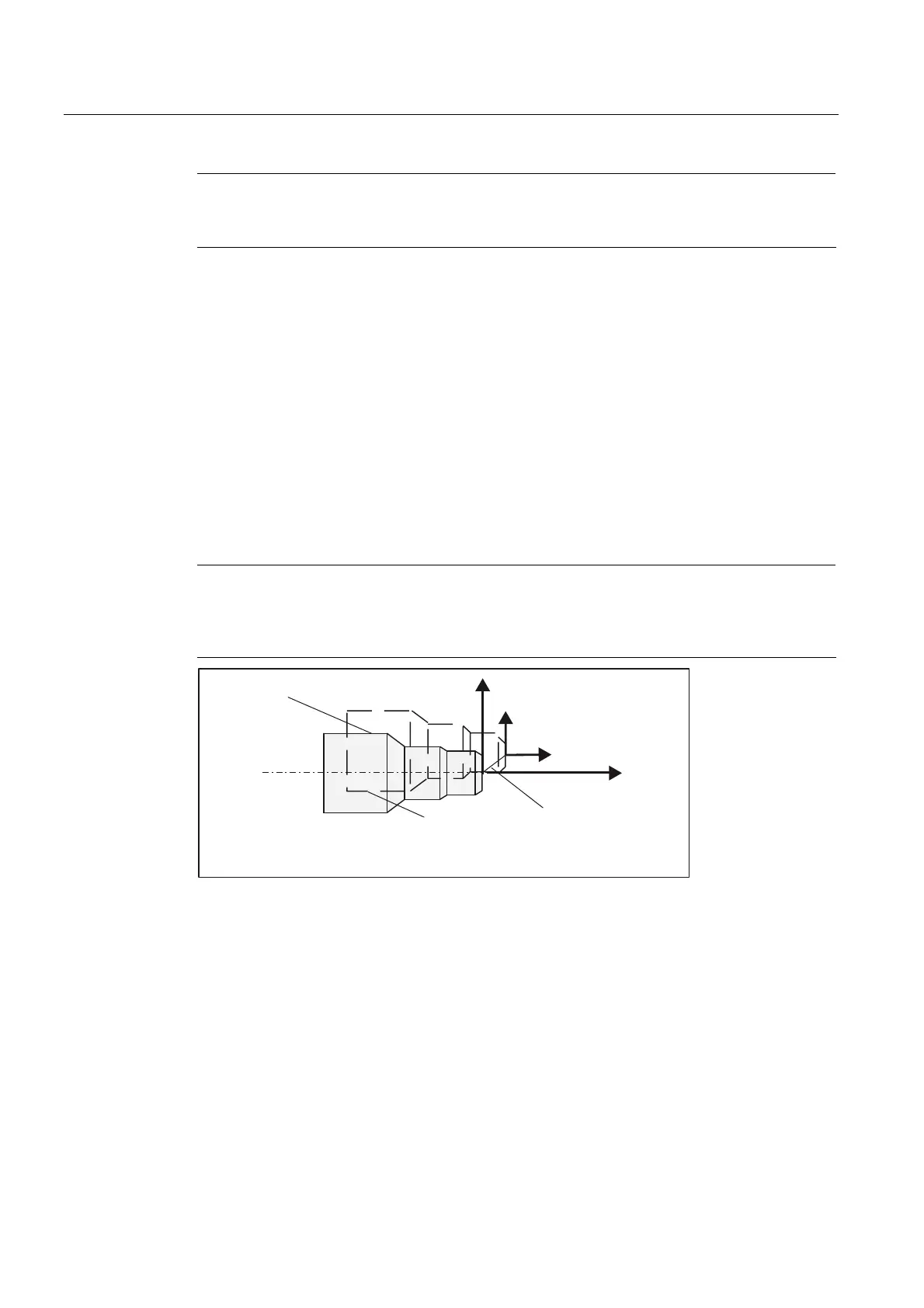

:RUNSLHFHRIIVHW

2IIVHW;=

:RUNSLHFH

$FWXDO

$FWXDO

;

;

=

=

:

:RUNSLHFHRULJLQDO

Figure 1-4 effect of the programmable offset

Programming

TRANS Z... ; programmable offset, deletes old instructions for offsetting, rotation, scaling

factor, mirroring

ATRANS Z... ; programmable offset, additive to existing instructions

TRANS ; without values: clears old instructions for offset, rotation, scaling factor,

mirroring

The instructions that contain TRANS or ATRANS each require a separate block.

Loading...

Loading...