Programming principles

1.2 Positional data

Turning Part 2: Programming (Siemens instructions)

Programming and Operating Manual, 05/2012, 6FC5398-5DP10-0BA0

29

1.2.4 Radius / diameter dimensions: DIAMOF, DIAMON, DIAM90

Functionality

For machining parts, the positional data for the X–axis (transverse axis) is programmed as

diameter dimensioning. When necessary, it is possible to switch to radius dimensioning in

the program.

DIAMOF or DIAMON assesses the end point specification for the X axis as radius or

diameter dimensioning. The actual value appears in the display accordingly for the

workpiece coordinate system.

For DIAM90, irrespective of the traversing method (G90/G91), the actual value of the

transverse axis is always displayed as a diameter. This also applies to reading of actual

values in the workpiece coordinate system with MEAS, MEAW, $P_EP[x] and $AA_IW[x].

Programming

DIAMOF ; Radius dimensioning

DIAMON ; Diameter dimensioning

DIAM90 ; diameter dimensioning for G90, radius dimensioning for G91

5

5

5

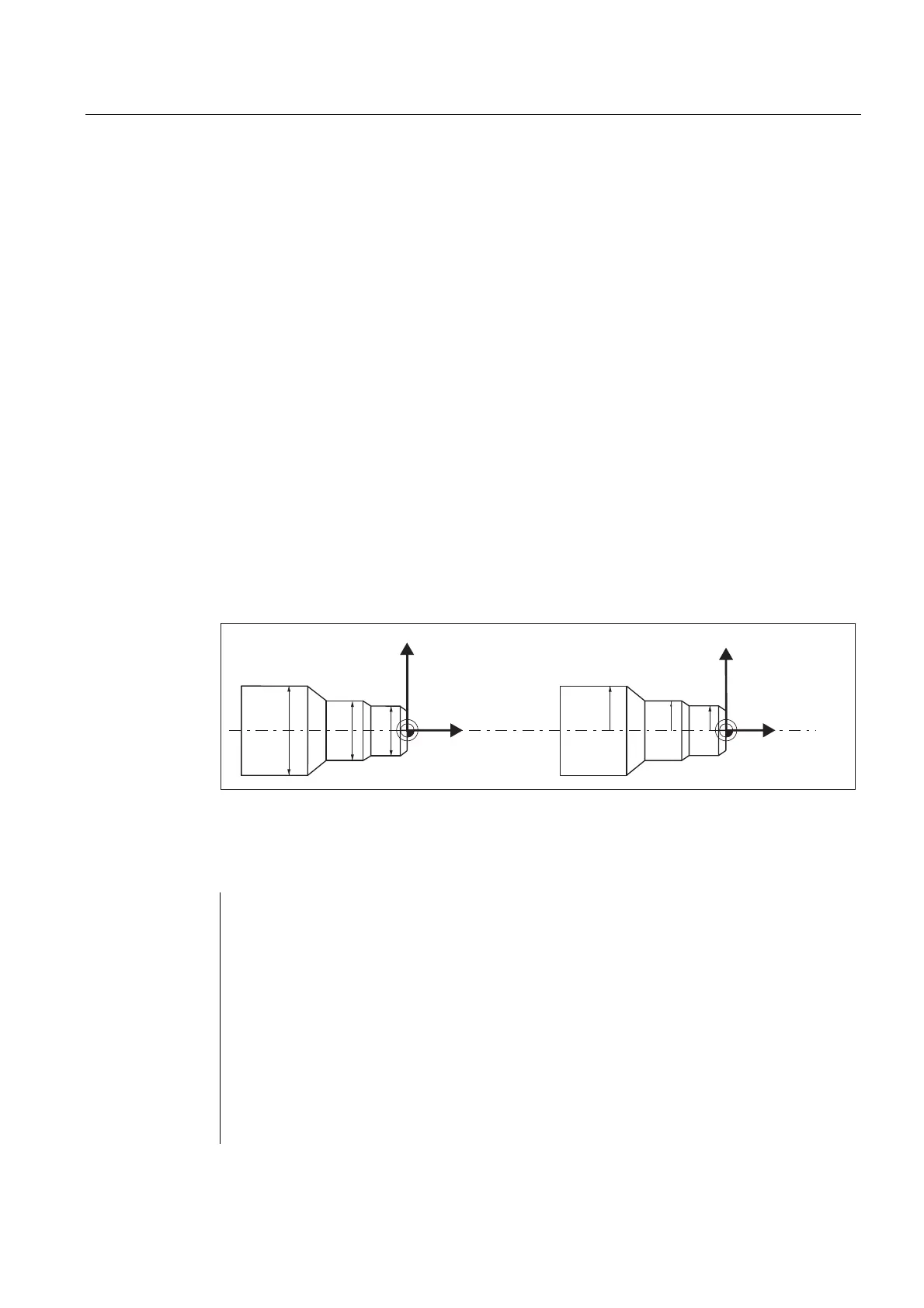

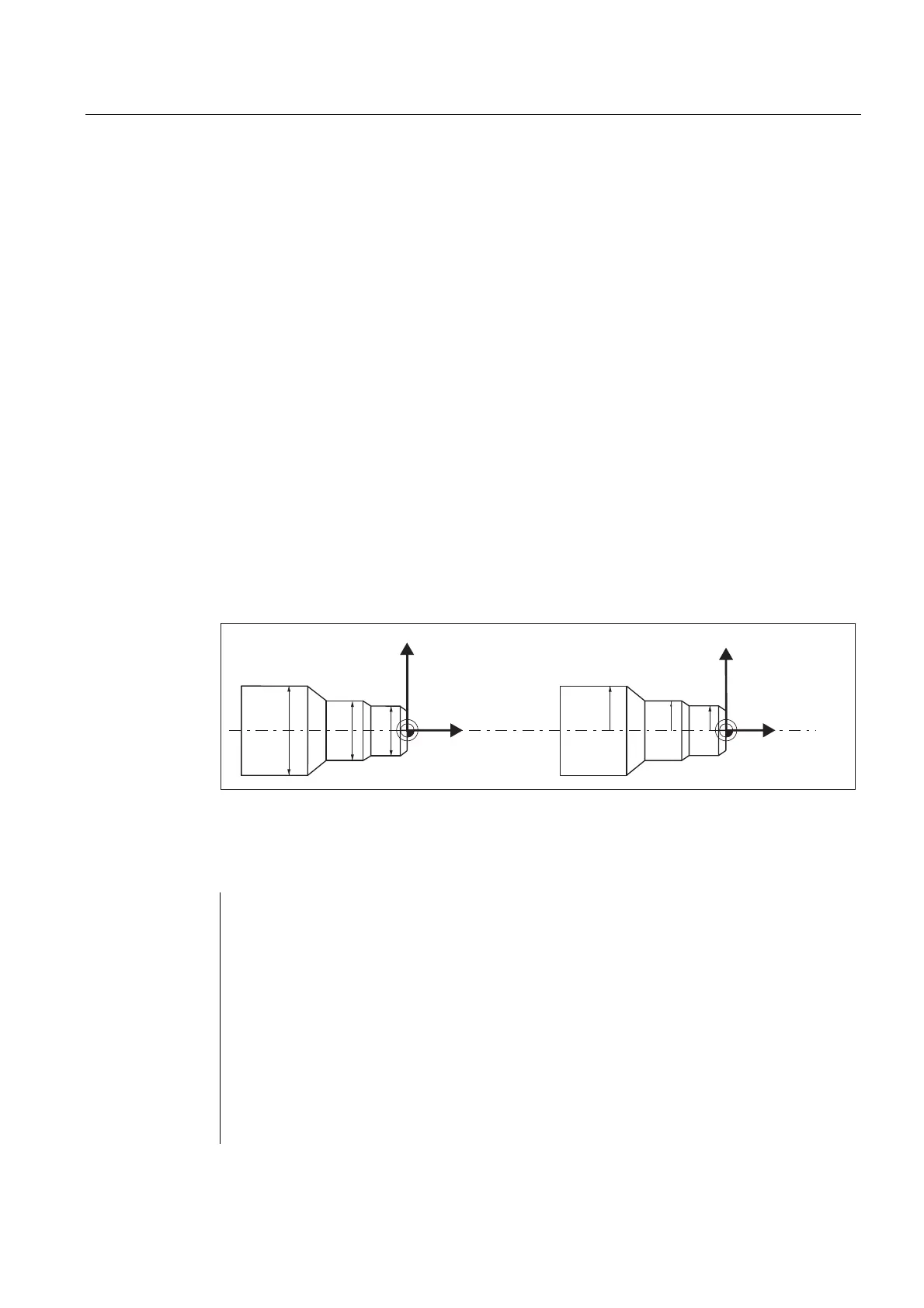

'LDPHWHUGLPHQVLRQV

',$021

7UDQVYHUVHD[LV

5DGLXVGLPHQVLRQLQJ

',$02)

7UDQVYHUVHD[LV

/RQJLWXGLQDOD[LV /RQJLWXGLQDOD[LV

;

;

:

:

= =

Figure 1-3 diameter and radius dimensioning for the traverse axis

Programming example

N10 G0 X0 Z0 ;Approach starting point

N20 DIAMOF Diameter input off

N30 G1 X30 S2000 M03 F0.8 ; X-axis = traverse axis active

; traverse to radius position X30

N40 DIAMON ; Diameter dimensions active

N50 G1 X70 Z-20 ; Traverse to diameter position X70 and Z-20

N60 Z-30

N70 DIAM90 ; diameter programming for absolute dimension and

; radius programming for incremental dimension

N80 G91 X10 Z-20 Incremental dimension

N90 G90 X10 Absolute dimensions

N100 M30 ;End of program

Loading...

Loading...