01.93 4 Monitoring Functions

4.6 Listing of the alarms/alarm description

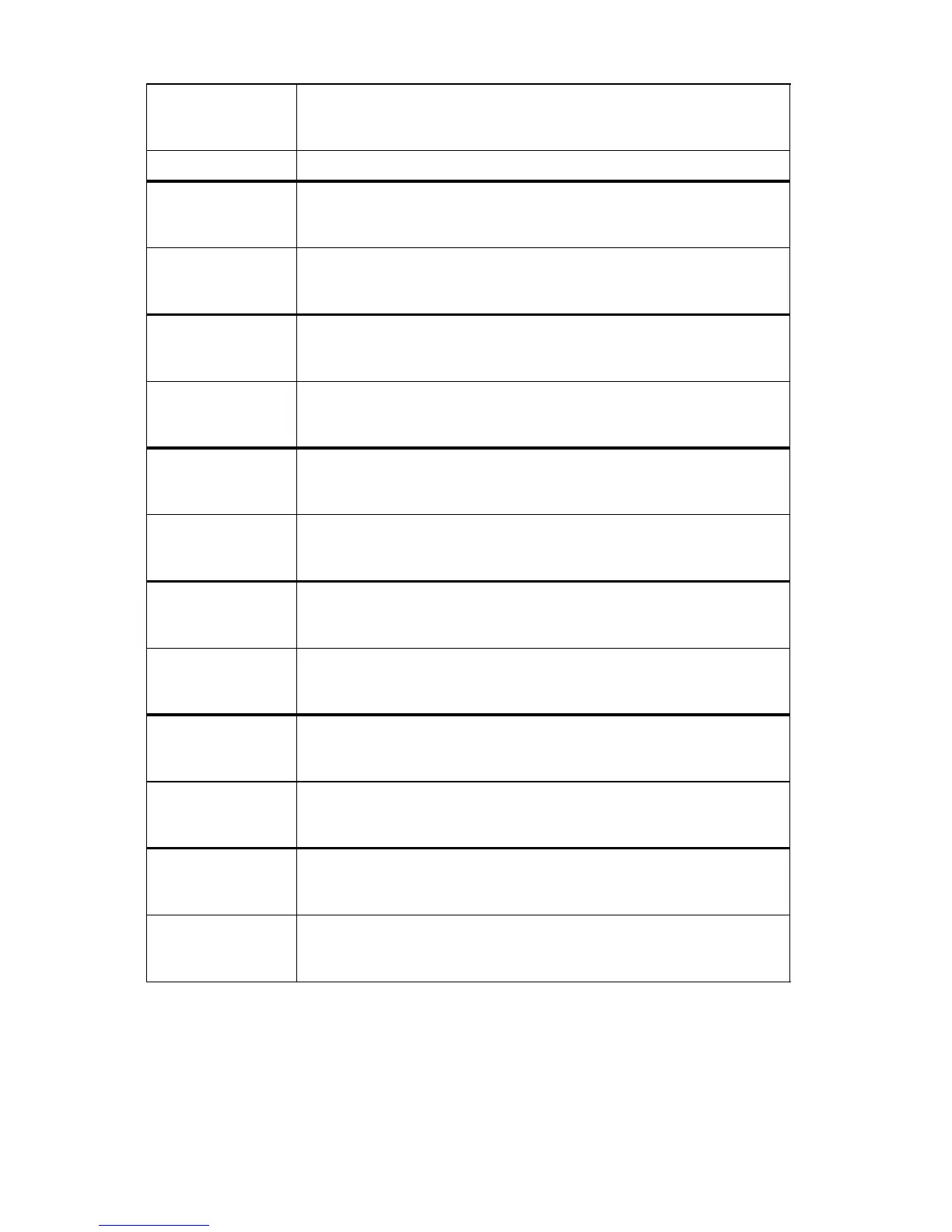

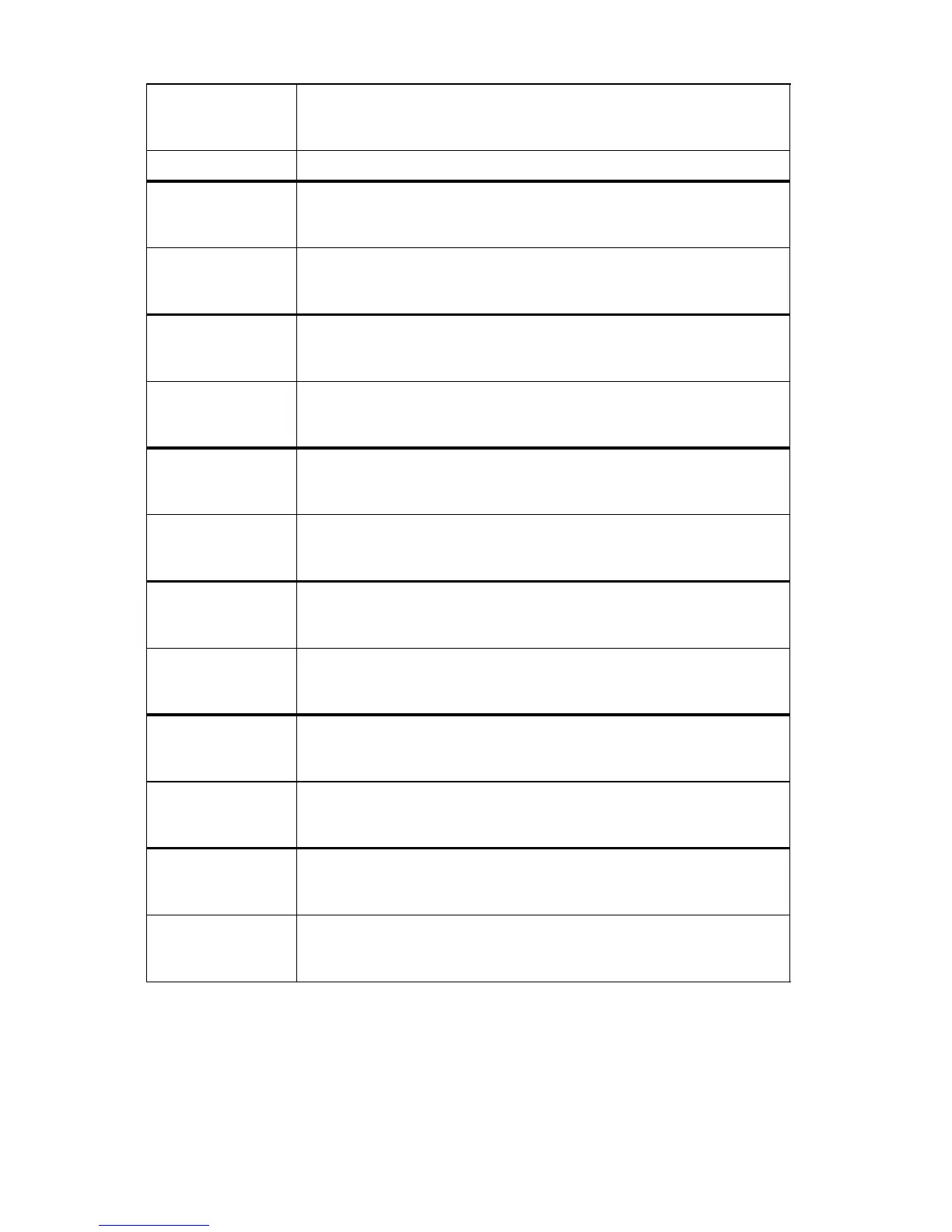

Alarm No.

Alarm Text:

2031

”Eval. (weighting) factor too high (MD 388*)”

Remarks: Alarm only on commissioning

Alarm No.

Alarm Text:

2032

”Stop during threading”

Reason:

Effect:

During thread cutting, the feed per revolution was stopped, and the

thread destroyed.

Inhibiting of NC START

Alarm No.

Alarm Text:

2034

”Speed reduction area”

Reason:

Remedy:

The software pre-limit was overshot, and the axis decelerated to the

reduced traverse rate

Check the program

Alarm No.

Alarm Text:

2035

”Feed limitation”

Reason:

Remedy:

The programmed feedrate is higher than the contouring feedrate,

based on the maximum feedrate of the axes.

Program a lower contouring feedrate

Alarm No.

Alarm Text:

2036

”G35 thread pitch decr. error”

Reason:

Remedy:

The pitch decrease in threading is so high that at the end of the thread

a diameter of less than, or equal to zero would result.

Program either a smaller pitch decrease or a shorter thread

Alarm No.

Alarm Text:

2037

”Programmed S value too high”

Reason:

Remedy:

The programmed spindle speed ”S” is higher than ”16000”.

Program a smaller spindle speed (the S value is limited to ”16000”

within the control).

Alarm No.

Alarm Text:

2038

”Path feed too large”

Reason:

Effect:

Remedy:

Axis velocity too great because of the programmed path velocity.

NC START disabled and setpoint relay drops out.

Observe permissible value range.

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0EP02 4-15

SINUMERIK 810T, GA3 (BN)

Loading...

Loading...