1 Introduction 10.91

1.9.2 Logging via CP315 with the SINUMERIK 840/880

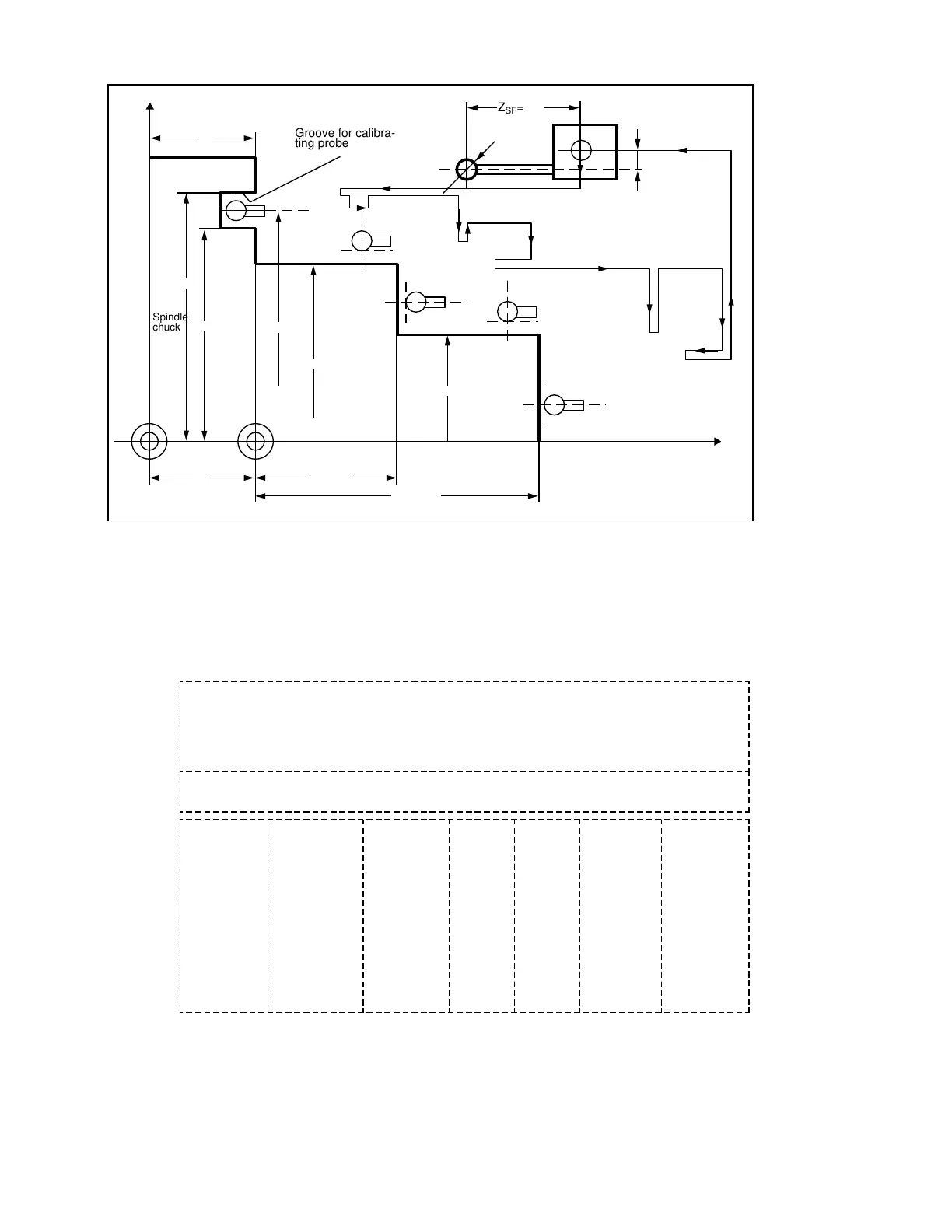

Z

X

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

Spindle

chuck

Groove for calibra-

ting probe

Z

SF

=50

d=10

F

X

SF

=25

N135

50

140

120

260

200±0,3

Workpiece

Measuring

point 3

Measuring

point 4

Measuring

point 1

Measuring

point 2

70 50±0,2

100±0,3

M

150±0,5

N30

N55

N60

N65

N80

N85

N105

N100

N110

N125

N130

W

– The following test log is to be output:

Column 12345678901234567890123456789012345678901234567890123456789012345678901234567890

10 20 30 40 50 60 70 80

Line

0001.0

4+1 decimal

place +

fixed point

from the PLC

3111.180

8 places

without sign

with decimal

point 4 places

before,

3 places after

decimal point

(R206)

3112.303

8 places

(R209)

1.123

5 places

(R200)

–0.001

5 places

(R203)

1.123*

5 places

(R212)

09:46:02

8 places

Part number . . . . . . :<23456789> (R40) Date: dd.mm.yy// / Page: No.

Order number . . . . . :<23456789> (R41)

Program number . . . :<23456789> (R43) Serial number . . . . :<23456789> (R44)

Measuring Setpoint Actual value Tolerance limit Setpoint Time of day

point + – difference

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

R parameters in brackets do not appear on the log. They only serve as an indication in which

columns or lines the parameter contents are entered.

1–40 ©

Siemens AG 1990 All Rights Reserved 6FC5197- AB70

SINUMERIK 840/850/880 (BN)

Loading...

Loading...