10.91 4 Measuring Cycles for Turning Machines

4.1 L972/L982 Tool measurement

Tool types 28, 37 and 38, R23=x1x2

With tool type 28, L1 and R

are determined.

With tool types 37 and 38, L1, L2 and R

are determined.

The first measuring point is measured in the abscissa and ordinate. The tool is then turned

through 180 degrees and the same cutting edge is measured again in the two axial directions.

The average values of the two measurements provide the L1 and L2 dimensions. The cutter

radius is determined from half the dimensional difference between measuring point 1 and

measuring point 2 in the ordinate.

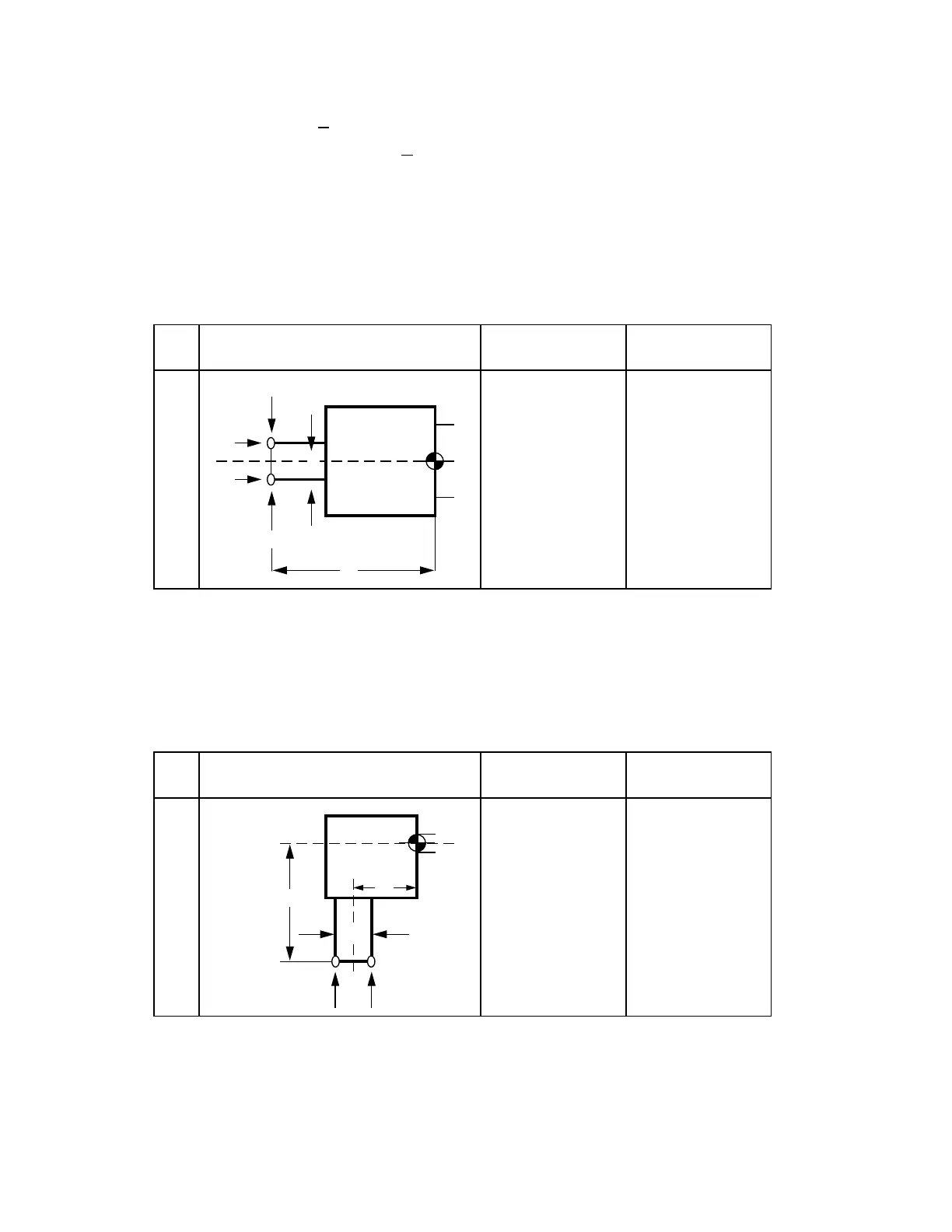

Axial tool

37

L1=0

L2, R

L1, L2, R

L2

Measuring point 2

Measuring point 1

L2

Axial tool form

Tool

type

Tool geometry

dimensions

Dimension

compensations

F

R

Calculation of tool geometry:

L1=(L1,1+L1,2)/2 L2=(L2,1+L2,2)/2 R=ABS((L1,1 – L1,22)/2)

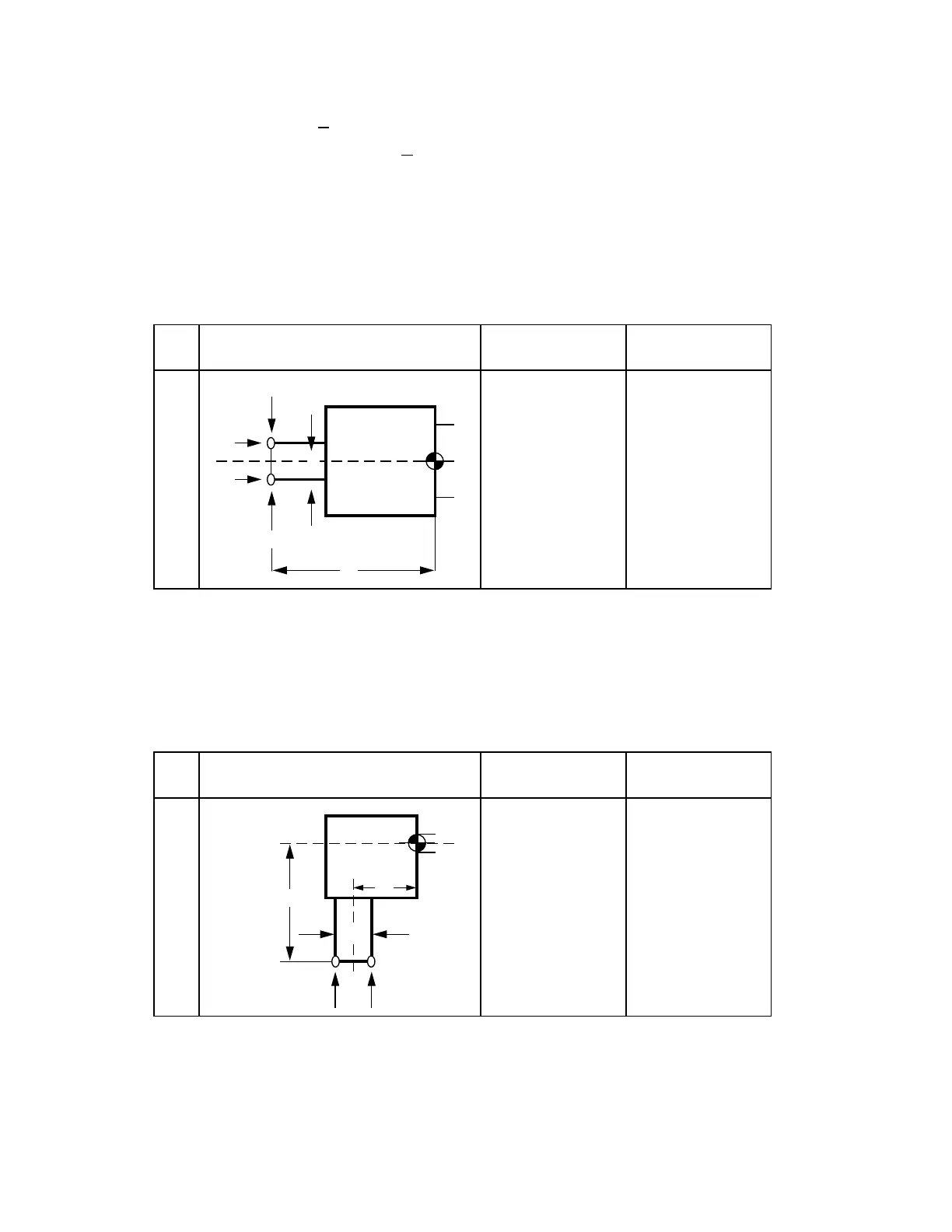

Radial tool

28

38

L1, L2=0, R

L1, L2, R

L1, R

L1, L2, R

Measuring

point 1

L1

R

Measuring

point 2

Axial tool form

Tool

type

Tool geometry

dimensions

Dimension

compensations

F

L2

Calculation of tool geometry:

L1=(L1,1+L1,2)/2 L2=(L2,1+L2,2)/2 R=ABS((L2,1 – L2,2)/2)

©

Siemens AG 1990 All Rights Reserved 6FC5197- AB70 4–7

SINUMERIK 840/850/880 (BN)

Loading...

Loading...