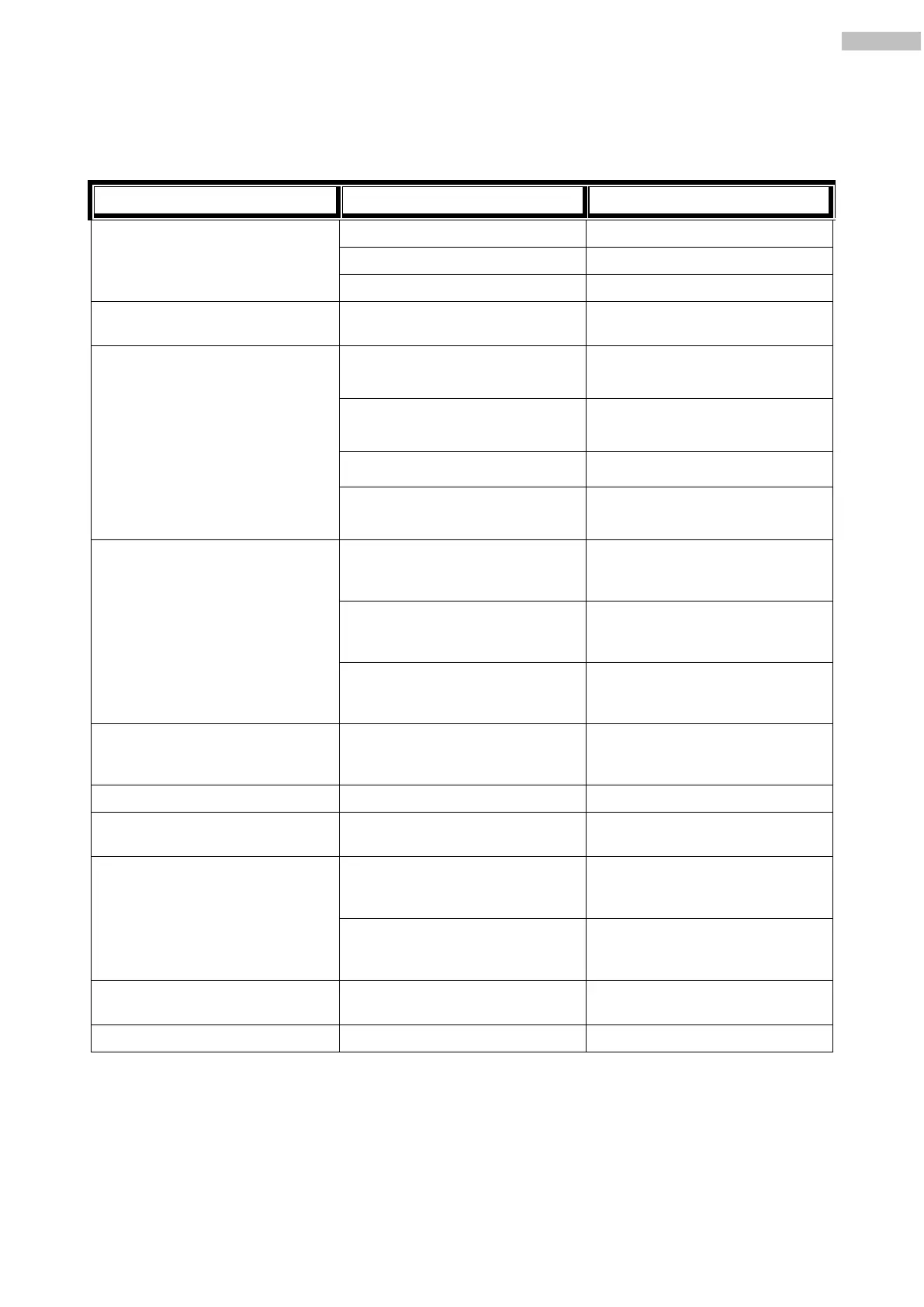

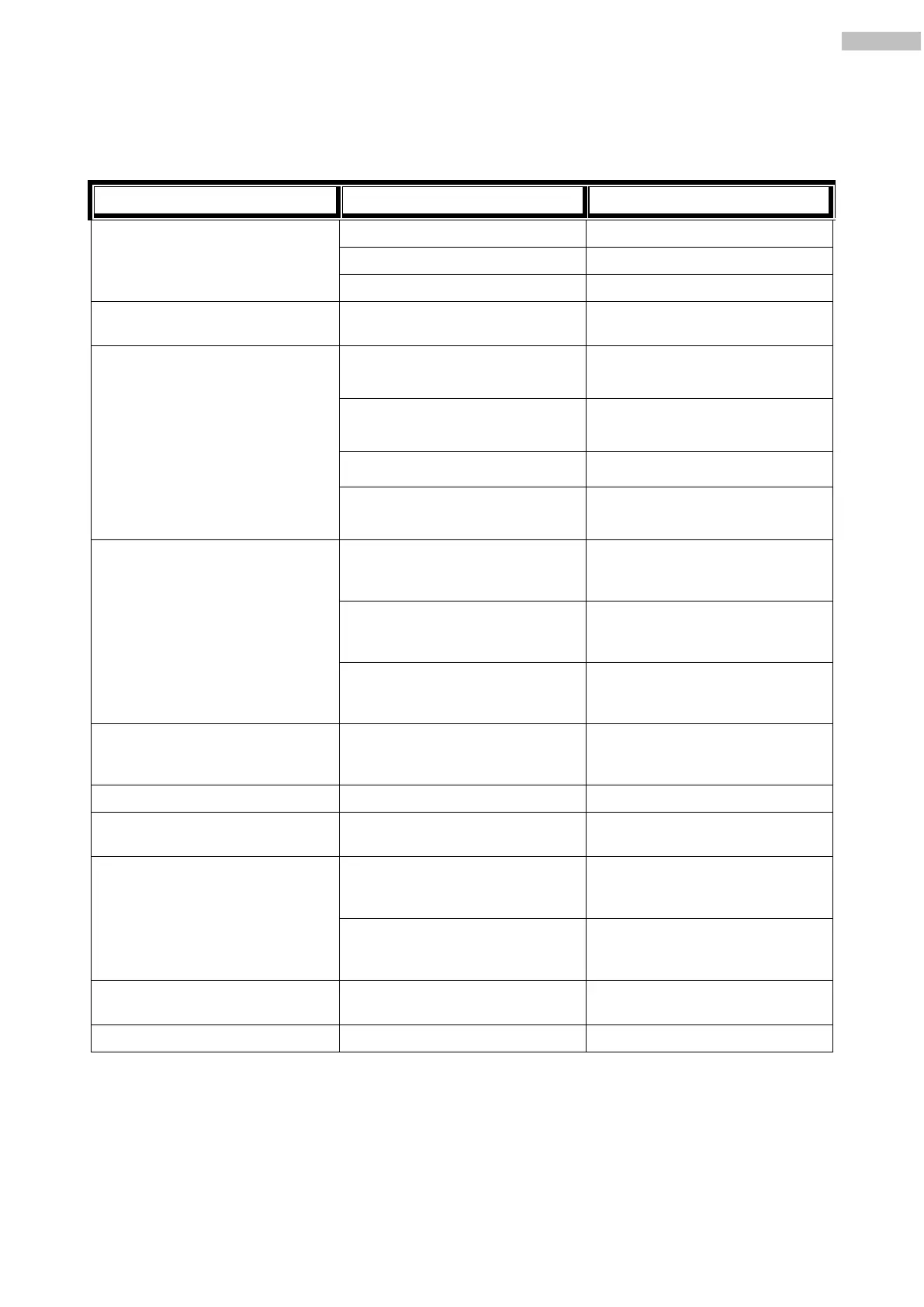

Not enough power to cut of bend

Replace blades or change cutting side

Motor not receiving correct current

Check engine for technical service

The bending plate doesn´t return to its original

position after the bend is complete

Defective inductive sensor

Check the sensor (1 open, 0 closed). Replace if

damaged

Not enough or un current reaching the machine,

the pilot light doesn´t come on

Lack of current reaching the electrical junction

box

Check site junction box to make sure electricity is

being produced

CHECK THE CURRENT FROM THE MAINS

FUSE HAS BLOWN ON THE JUNCTION BOX

The pilot light is on but the machine doesn´t work

The machine isn´t correctly connected

Check that all phases are complete. Check the

fuse in the machines electrical box

EMERGENCY STOP BUTTON IS DEPRESSED

SECURITY FEATURES ARE ACTIVATED

MAKE SURE ALL DOORS, EMERGENCY STOP

BUTTONS AND PLASTIC TABLE TOP GUARD ARE

IN CORRECT POSITION

230v or 400v connection. The connection is

correct but the machine doesn´t have enough

power.

Unstable electricity supply

Check the electricity supply if the voltage is

inferior to 230v or 400v the machine won´t work.

A tension stabiliser is recommended

The machine loses oil through the gear box

Rubber washer deteriorated.

When bend is finished the plate doesn´t stop at

the original position

Defective inductive sensor

Check the sensor (1 open, 0 closed). Replace if

damaged

The bending plate doesn’t stop immediately when

the pedal is released

Check the motor brake and tighten the springs

leaving a uniform gap between the disc and the

plate of .3 to .4mm.

THE MOTOR BRAKE IS NOT OPERATIONAL

Strange noise from within the gearbox

Deterioration of some of the internal components

Dismantle the gearbox and check bearings and

grooves. Replaced damaged elements

Strange noise from the motor

Misfunction of one of its components

Find out the source of the noise and repair

Loading...

Loading...