GD1 Page 43 of 76 850-816926-EN R06

6. TROUBLESHOOTING

Simtronics shall do all service and repairs. Troubleshooting ashould be performed by the

used as described below.

The detector can also give fault messages if the mounting brackets are not sufficiently

stable over time, for example with temperature changes or passing trucks resulting in the

GD1 coming temporarily out of alignment. Before troubleshooting is commenced the

rigidity of the mounting structure should be checked.

The most common issues are the following:

• Misinterpretation of ppm*m as ppm. Described in section 10.4.

• Poor alignment. Please be aware that it is the absolute transmission that should be

optimized, not the relative transmission (section 3.3).

• Interference from a second transmitter as described in section 6.3.

Troubleshooting should always start by inspecting the detector’s lenses for contamination

and/or defects. The following list may be helpful:

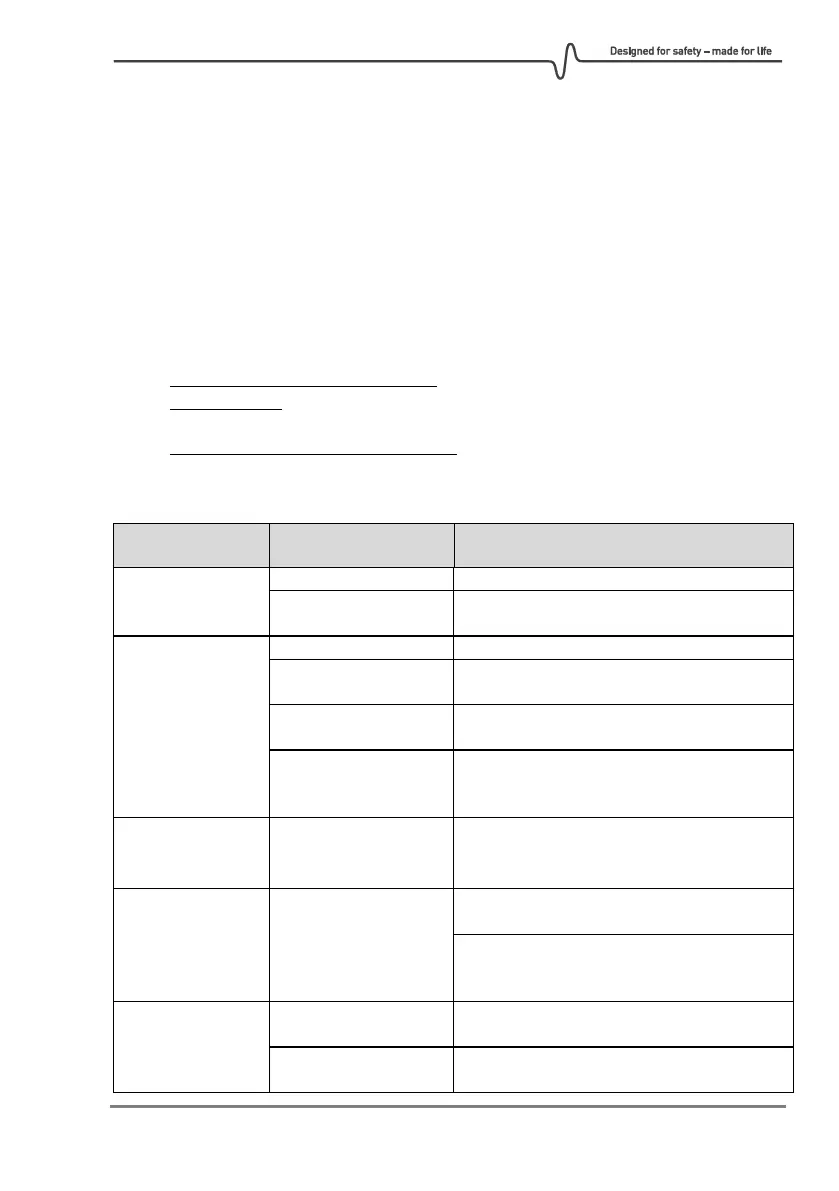

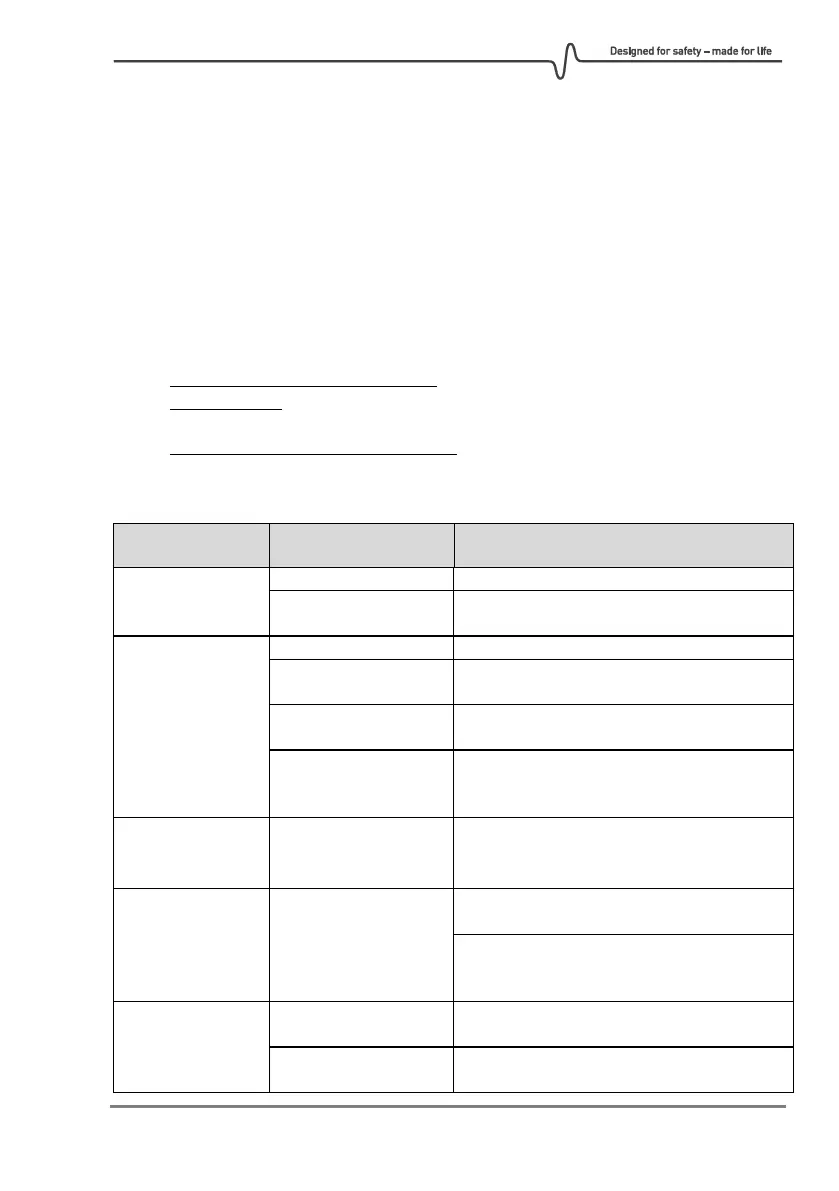

Possible source of

problem

Clean optics

warning

(3 mA)

Clean optics (see section 5.2).

Detector out of

alignment.

Realign detector (see chapter 0).

Clean optics (see section 5.2).

Detector out of

alignment.

Realign detector (see chapter 0).

Objects that block the

measuring path.

Remove objects that block.

Detector in alignment

or service mode

Reboot detector by Service Interface

(Ethernet), HART®, or by

cutting/reconnecting power.

Check error code in

the Service interface

Status screen.

See section 0 for a description and

suggestion on how to solve the issue.

No power to the

detector.

Verify with multi meter in the Junction box

that detector has power.

Check both detector and system cable

wires on terminal 1 and 2 in the junction

box.

No wireless or

cable Ethernet

connection

Make sure your browser is connected to

the GD1 wireless network.

Check that the terminal adapter is securely

connected to terminals 3 – 6

Loading...

Loading...