TO

REMOVE

OIL

WICK

HOLDER

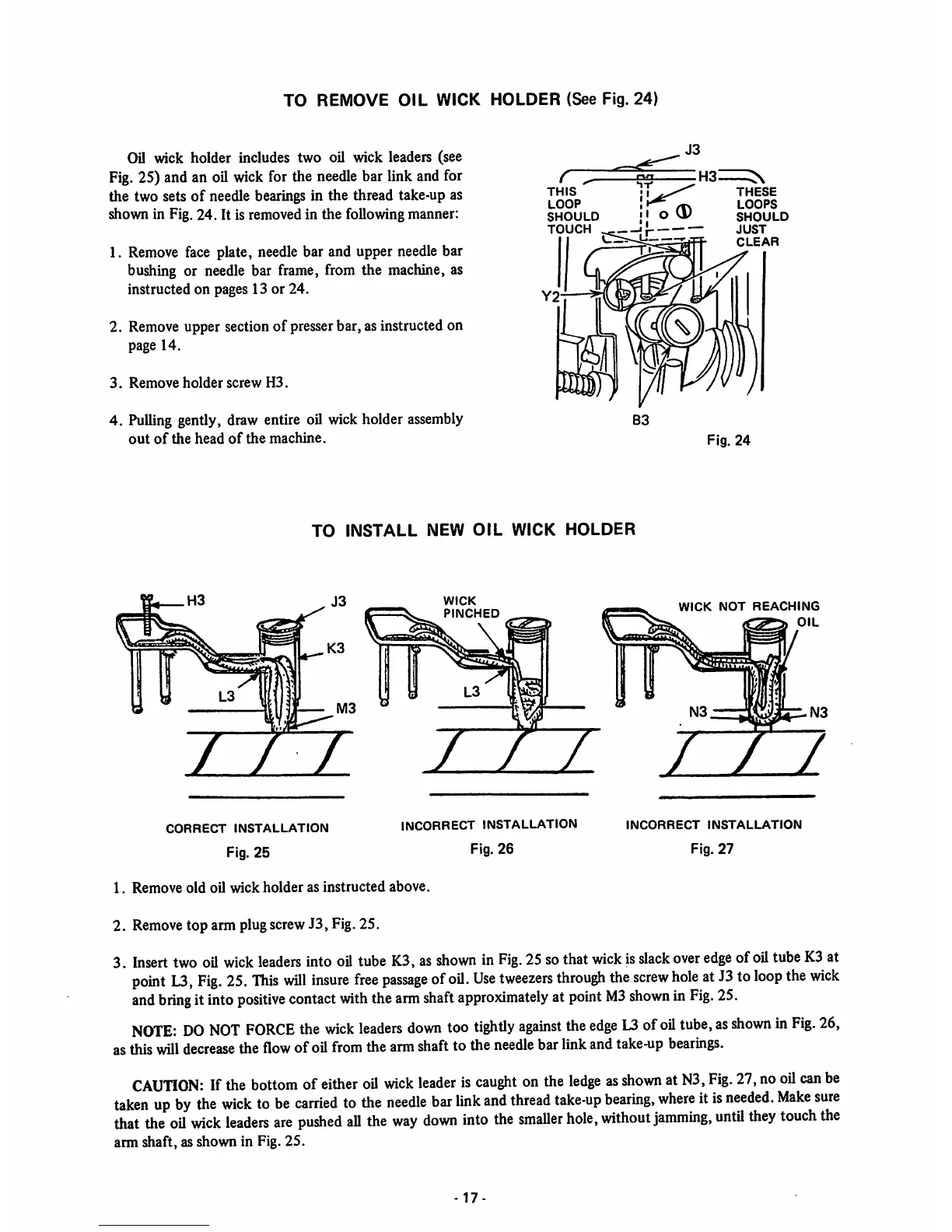

(See Fig.

24)

Oil wick holder includes two oil wick leaders (see

Fig. 25) and an oil wickfor the

needle

bar link and for

the two sets

of

needle bearings in the thread take-up as

shown in Fig.

24.

It is removed in

the

following manner:

1. Remove face plate, needle bar and upper needle bar

bushing or needle bar frame, from the machine, as

instructed on pages 13 or

24.

2. Remove upper section

of

presser bar, as instructed on

page 14.

3.

Remove

holder

screw

H3.

4.

Pulling

gently, draw entire oil wickholder

assembly

out

of

the

head

of

the

machine.

THIS

LOOP

SHOULD

TOUCH

THESE

LOOPS

SHOULD

JUST

CLEAR

Fig.

24

TO

INSTALL

NEW

OIL

WICK

HOLDER

i~r-T

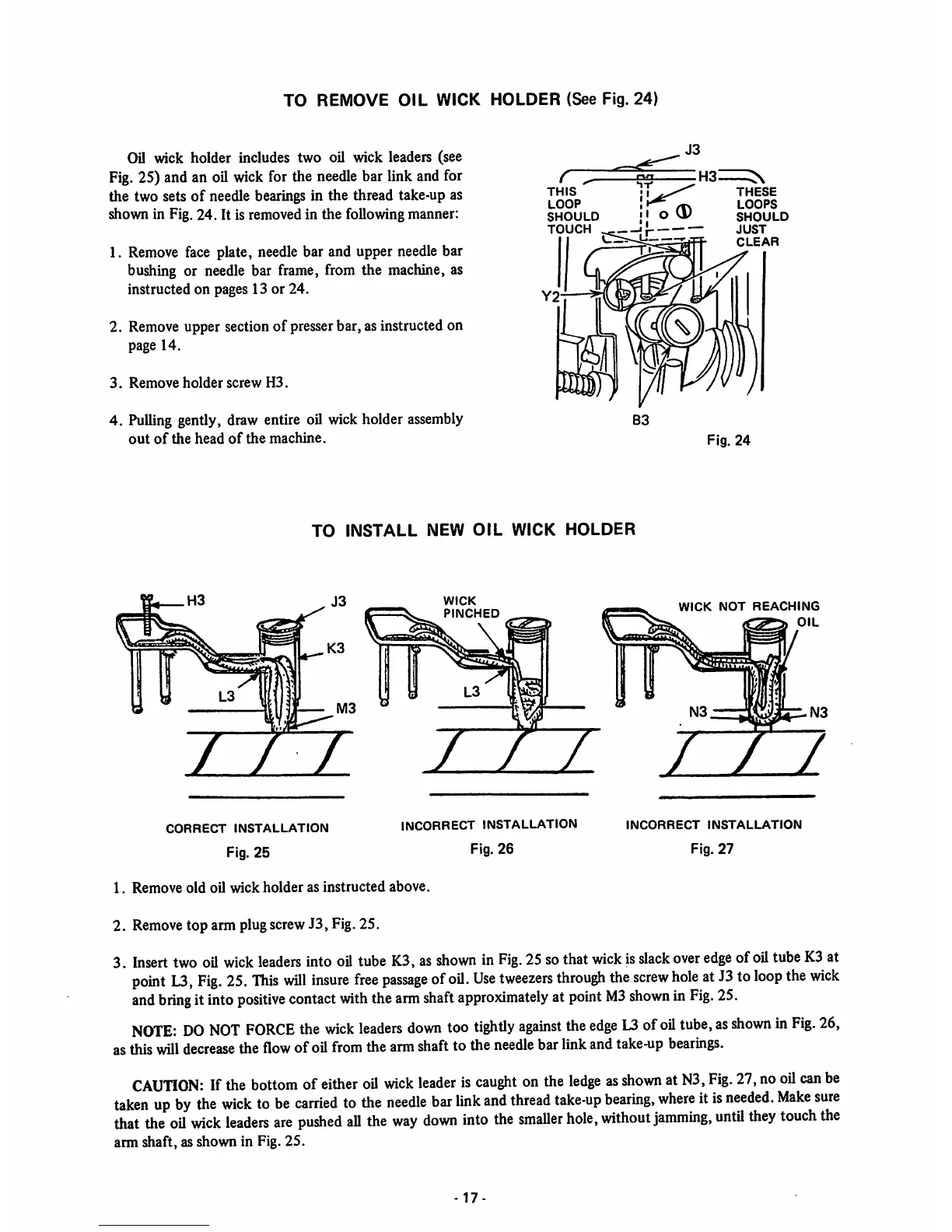

CORRECT

INSTALLATION

Fig.

25

WICK

PINCHED

7

INCORRECT

INSTALLATION

Fig.

26

WICK

NOT

REACHING

OIL

TTl

INCORRECT

INSTALLATION

Fig.

27

1.

Remove

old

oil

wick

holder

as

instructed

above.

2.

Remove

top arm plugscrewJ3, Fig.25.

3.

Insert

two

oil

wick

leaders

into

oil

tube

K3,

as

shown

in

Fig.

25sothat

wick

is

slack

over

edge

ofoil

tube

K3

at

point

L3,

Fig.

25.

This

will

insure

free

passage

of

oil.

Use

tweezers

through

the

screw

hole

at

J3

to

loop

the

wick

and

bring

it

into

positive

contact

with

the

arm

shaft

approximately

at

point

M3

shovm

in

Fig.

25.

NOTE:

DO

NOT

FORCE

the

wick

leaders

down

too

tightly

against

the

edge

L3

of

oil

tube,

as

shown

in

Fig.

26,

as

this

will

decrease

the

flow

ofoil

from

the

arm

shaft

to the

needle

bar

link

and

take-up

bearings.

CAUTION:

If

the

bottom

of

either

oil

wick

leader

is

caught

on

the

ledge

as

shown

at

N3,

Fig.

27,

no

oil

can

be

taken

up

by

the

wick

to

be

carried

to

the

needle

bar

link

and

thread

take-up

bearing,

where

it

is

needed.

Make

sure

that

the

oil

wick

leaders

are

pushed

all

the

way

down

into

the

smaller

hole,

without

jamming,

untU

they

touch

the

arm

shaft, as shown in Fig.

25.

17-

Loading...

Loading...