TO

TIME

THE

SEWING

HOOK

AND

ALSO

SET

THE

SEWING

HOOK

SIDEWISE

IN

RELATION

TO

THE

NEEDLE

PREPARATION:

Remove presser foot, slide plate, throat plate and

feed dog.

On compound feed varieties, set stitch length

to

zero (setting feed to zero is not required on drop

feed machine).

CHECK:

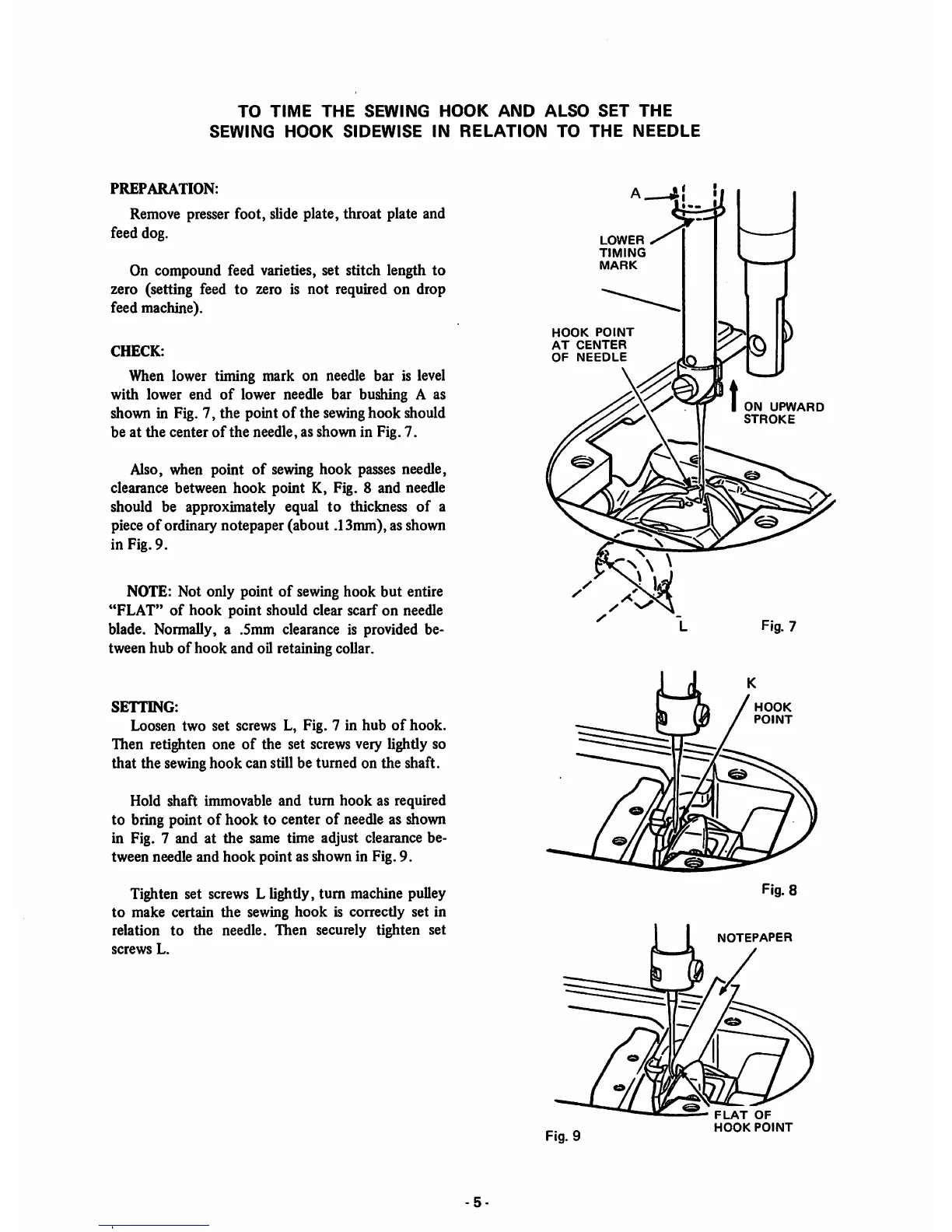

When lower timing mark on needle bar is level

with lower end

of

lower needle bar bushing A as

shown in Fig. 7, the point

of

the sewing

hook

should

be at

the

center

of

the

needle, as shown in Fig. 7.

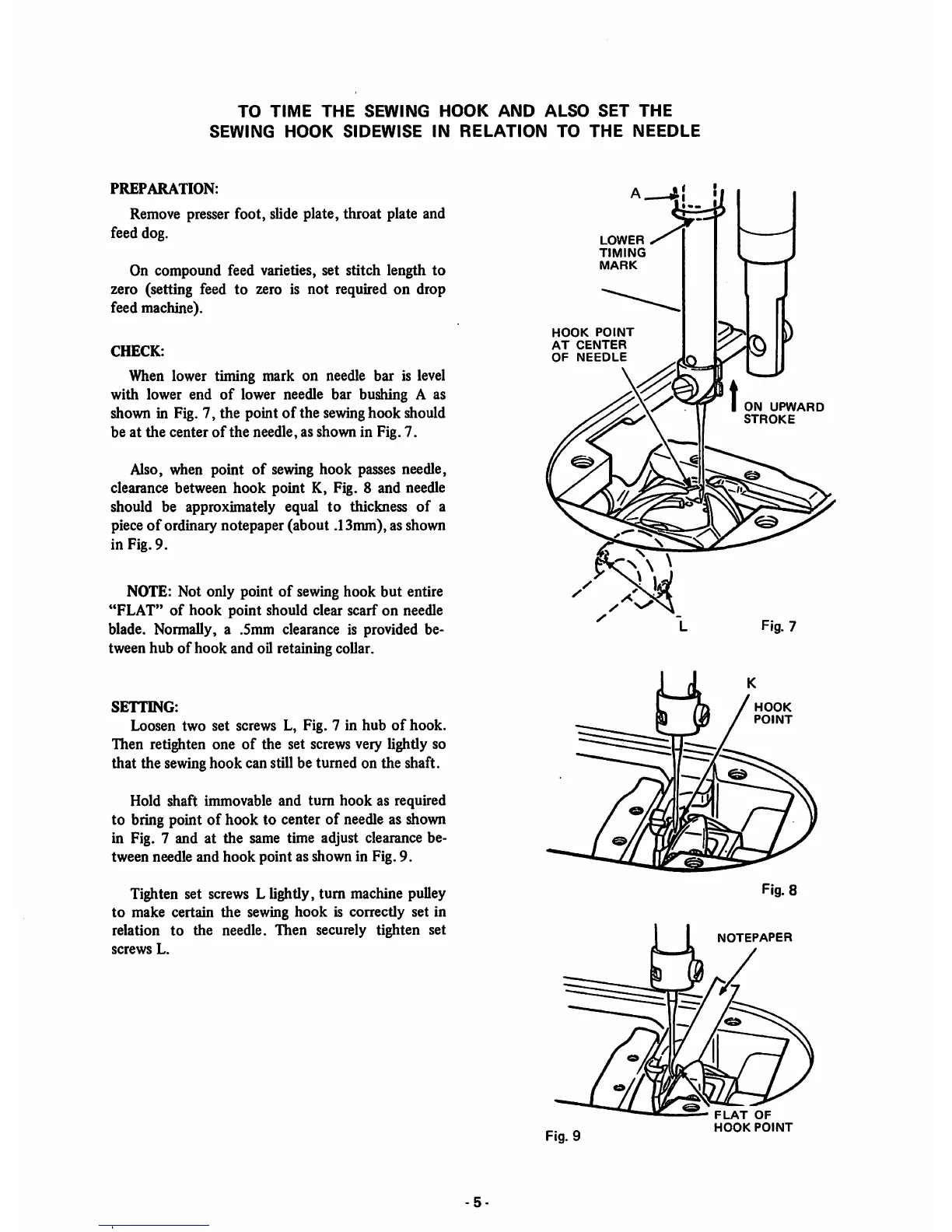

Also, when point

of

sewing hook passes needle,

clearance between

hook

point K, Fig. 8 and needle

should be approximately equal to thickness

of

a

piece

of

ordinary notepaper (about .13mm), as shown

in Fig. 9.

NOTE: Not only point

of

sewing hook

but

entire

"FLAT"

of

hook

point

should clear scarf on needle

blade. Normally, a .5mm clearance is provided be

tween hub

of

hook

and oil retaining collar.

SETTING:

Loosen two set screws L, Fig. 7 in

hub

of

hook.

Then retighten one

of

the set screws very lightly so

that the sewing hook can still be turned on the shaft.

Hold shaft immovable and turn

hook

as required

to bring point

of

hook to center of needle as shown

in Fig. 7 and at the same time adjust clearance be

tween needle and

hook

point as shown in Fig. 9.

Tighten set screws L lightly, turn machine pulley

to

make certain the sewing

hook

is correctly set in

relation

to

the

needle.

Then

securely tighten set

screws

L.

LOWER

TIMING

MARK

HOOK

POINT

AT

CENTER

OF

NEEDLE

Fig. 9

ON

UPWARD

STROKE

Fig. 7

HOOK

POINT

Fig. 8

NOTEPAPER

FLAT

OF

HOOK

POINT

Loading...

Loading...