SERVICE

INSTRUCTIONS

FOR

COMPOUND

FEED

SYSTEM

591C

CLASS

MACHINES

Servicing instructions for

59ID

Gass Machines also apply

to

the

59IC

Gass with

the

exception

of

the following

special instructions.

NEEDLE

BAR

FRAME

DRIVING

LINKAGE

ADJUSTMENT

1.

Set

machine

feed

to

zero.

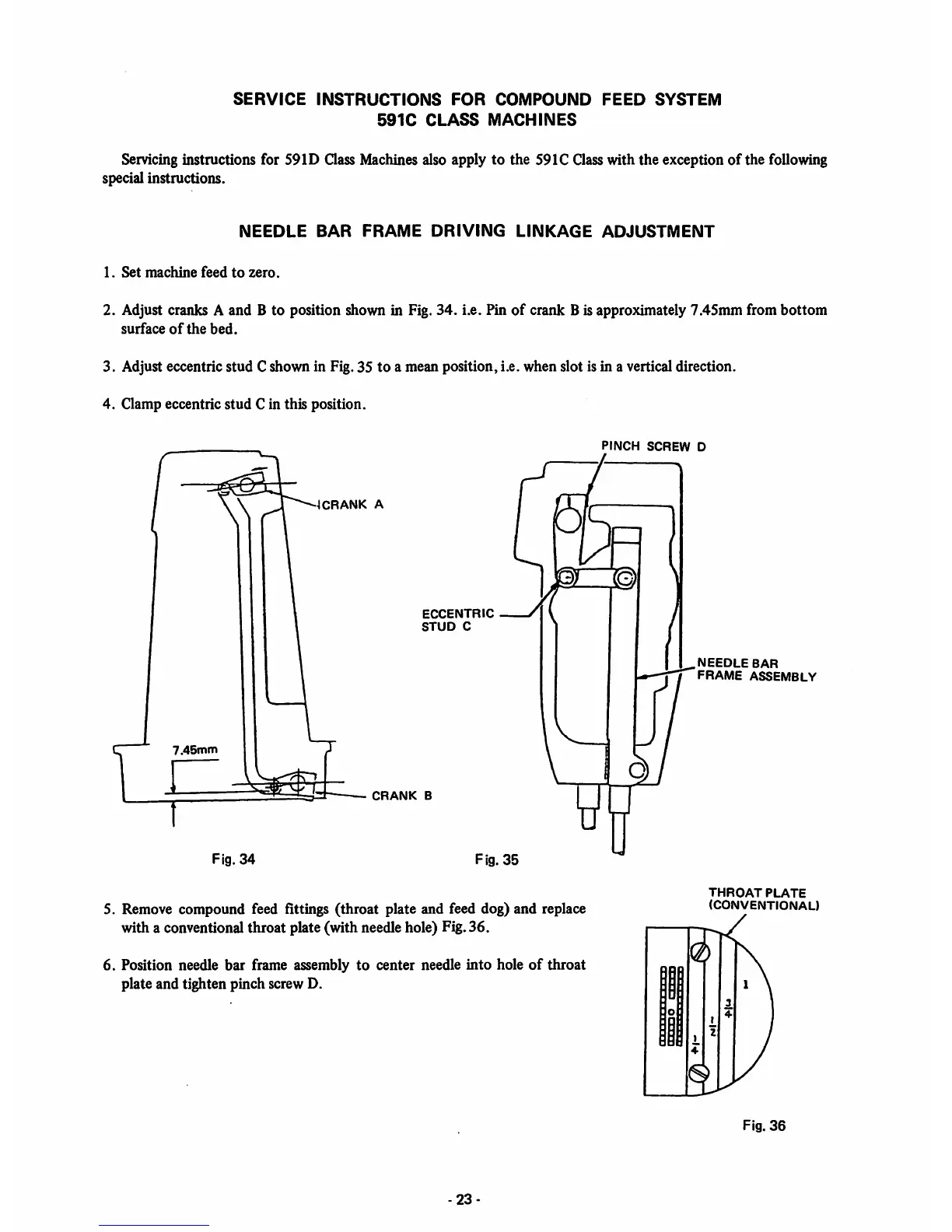

2. Adjust cranks A and B to position shown in Fig. 34. i.e. Pin

of

crank Bis approximately 7.45mm from bottom

surface

of

the

bed.

3. Adjust eccentric stud C shown in Fig.35 to a mean position, i.e. when slot is in a vertical direction.

4.

Gamp

eccentric stud C in this position.

7.45tnm

Fig.

34

I

CRANK

A

ECCENTRIC

STUD

C

CRANK

B

Fig.

35

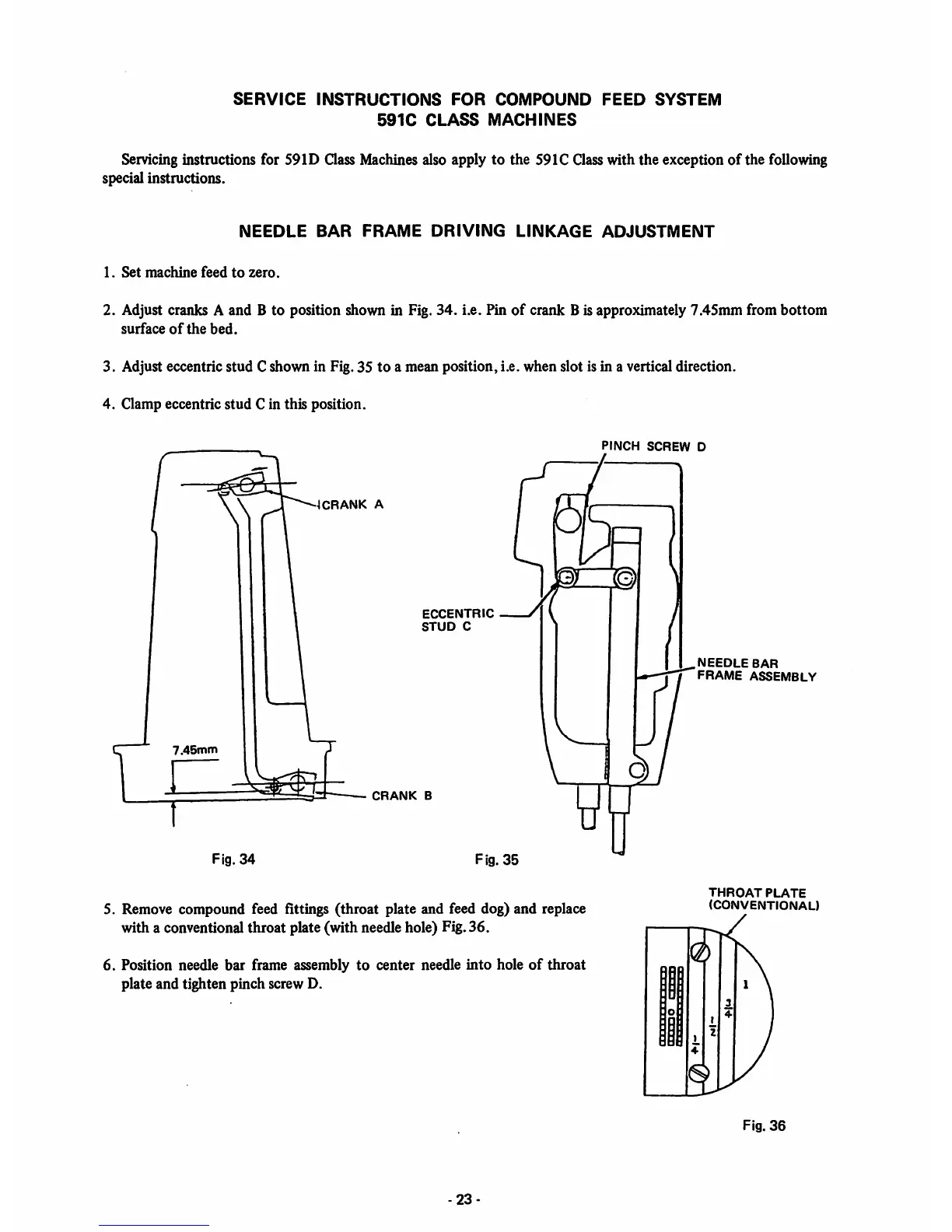

5. Remove compound feed fittings (throat plate and feed dog) and replace

with a conventional throat plate (with needle hole) Fig.36.

6. Position needle

bar

frame assembly to center needle into hole

of

throat

plate and tighten pinch screw D.

23

PINCH

SCREW

D

NEEDLE

BAR

FRAME

ASSEMBLY

THROAT

PLATE

(CONVENTIONAL)

Fig.

36

Loading...

Loading...