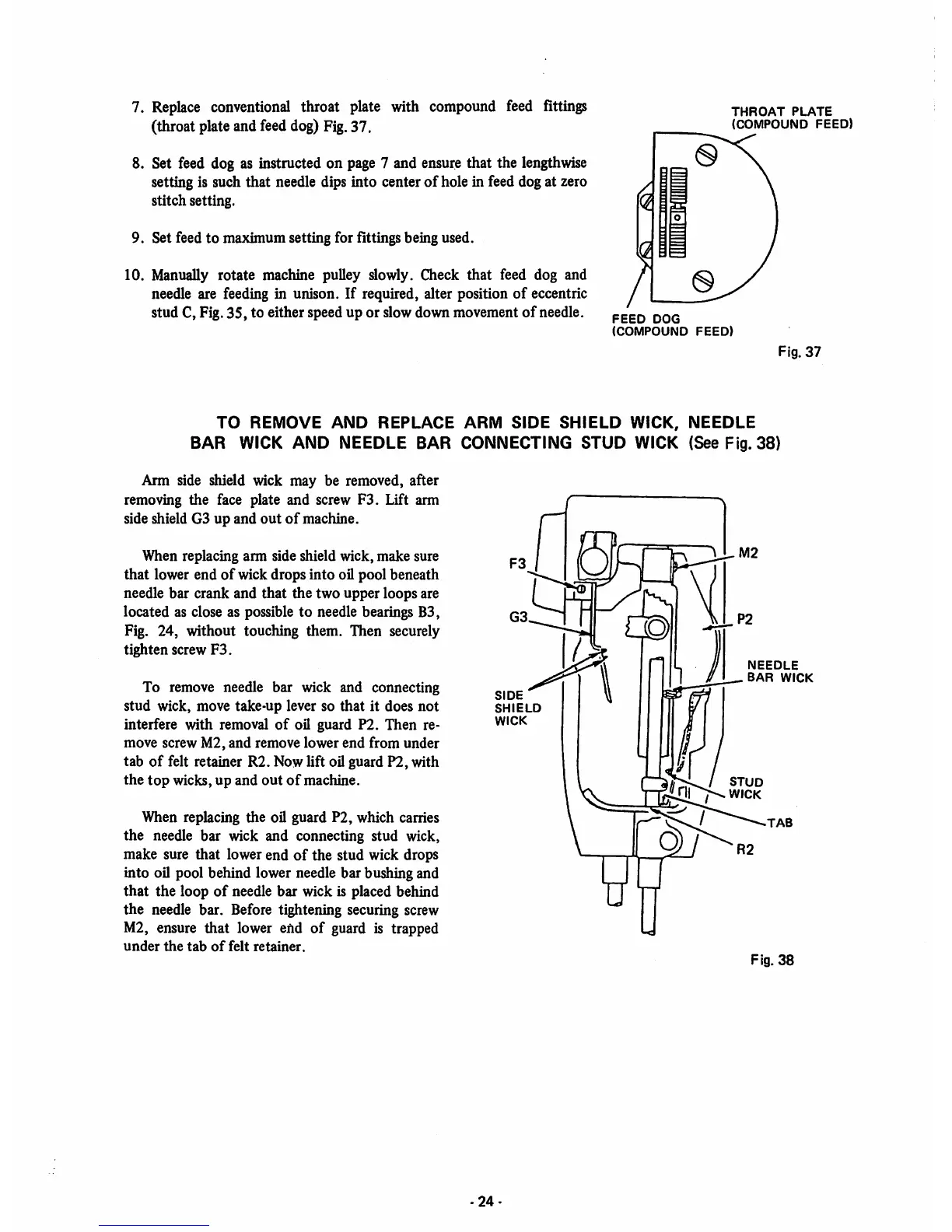

7.

Replace

conventional throat plate with compound feed fittings

(throat plate and feeddog) Fig.37.

8. Set feed dog as instructed on page 7 and ensure that the lengthwise

setting is such that needle dips into center

of

hole in feed dog at zero

stitch setting.

9. Set feed

to

maximum setting for fittings being used.

10. Manually rotate machine pulley slowly. Check that feed dog and

needle are feeding in unison. If required, alter position

of

eccentric

stud C, Fig.35, to either speed up or slow down movement of needle.

THROAT

PLATE

(COMPOUND

FEED)

FEED

DOG

(COMPOUND

FEED)

Fig.

37

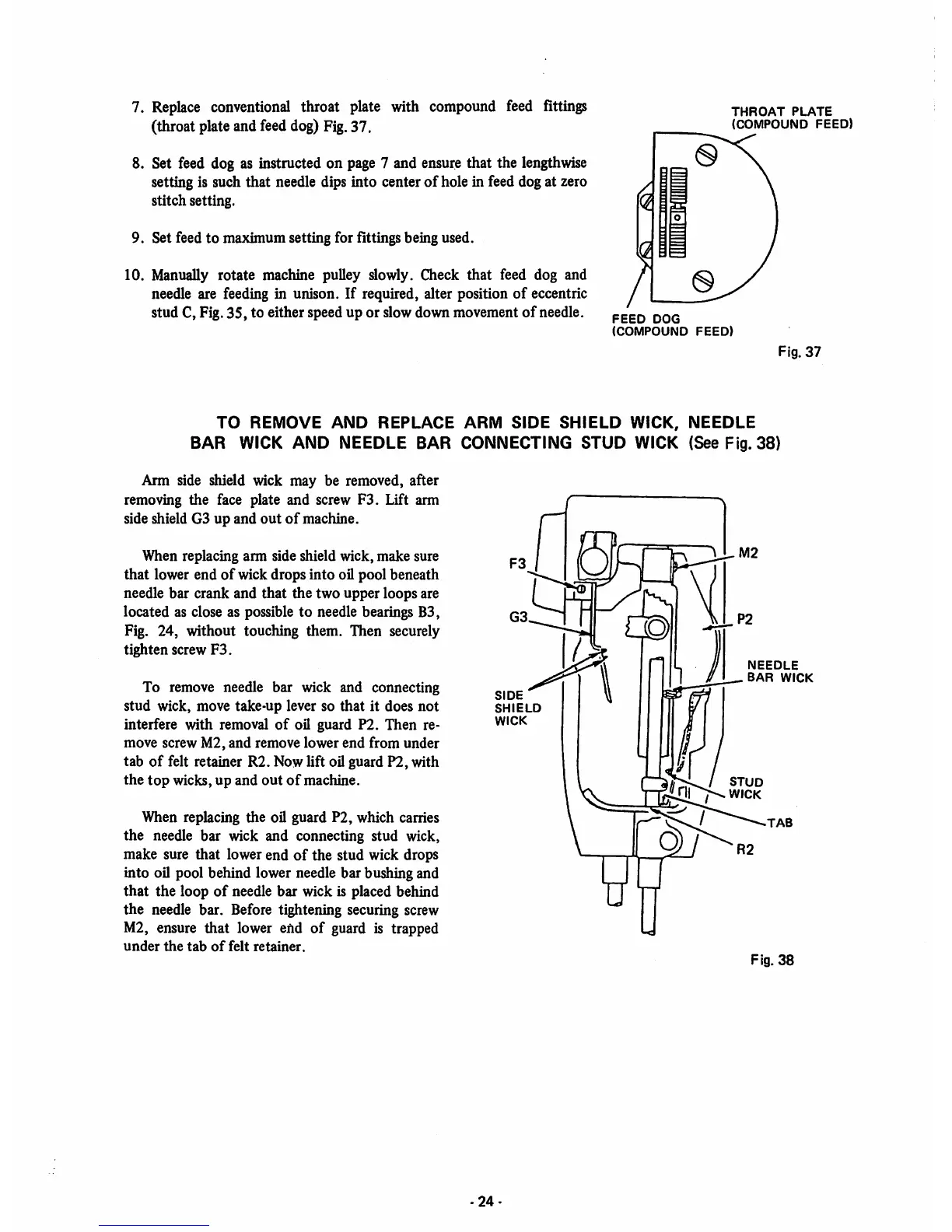

TO

REMOVE

AND

REPLACE

ARM

SIDE

SHIELD

WICK,

NEEDLE

BAR WICK AND NEEDLE BAR CONNECTING STUD WICK (See Fig. 38)

Arm side shield wick may be removed, after

removing the face plate and screw F3. Lift arm

side shield G3 up and

out

of

machine.

When replacing arm side shield wick,

make

sure

that

lower end

of

wick drops

into

oil pool beneath

needle bar crank and

that

the two upper loops are

located as close as possible to needle bearings B3,

Fig. 24, without touching them. Then securely

tighten screw

F3.

To remove needle bar wick and connecting

stud

wick, move take-up lever so

that

it does

not

interfere with removal

of

oil guard P2. Then re

move screw M2,

and

remove lower

end

from

under

tab

of

felt retainer R2. Now lift oil guard P2, with

the

top

wicks, up and

out

of

machine.

When replacing the oil guard P2, which carries

the needle bar wick and connecting stud wick,

make sure that lower end

of

the stud wick drops

into oil pool behind lower needle bar bushing and

that

the loop

of

needle

bar

wick is placed behind

the needle bar. Before tightening securing screw

M2, ensure

that

lower end

of

guard is trapped

under

the

tab

of

felt

retainer.

SIDE

SHIELD

WICK

-24-

NEEDLE

BAR

WICK

„ STUD

ni WICK

TAB

Fig.

38

Loading...

Loading...