SKF Machine Condition Advisor 23

User Manual

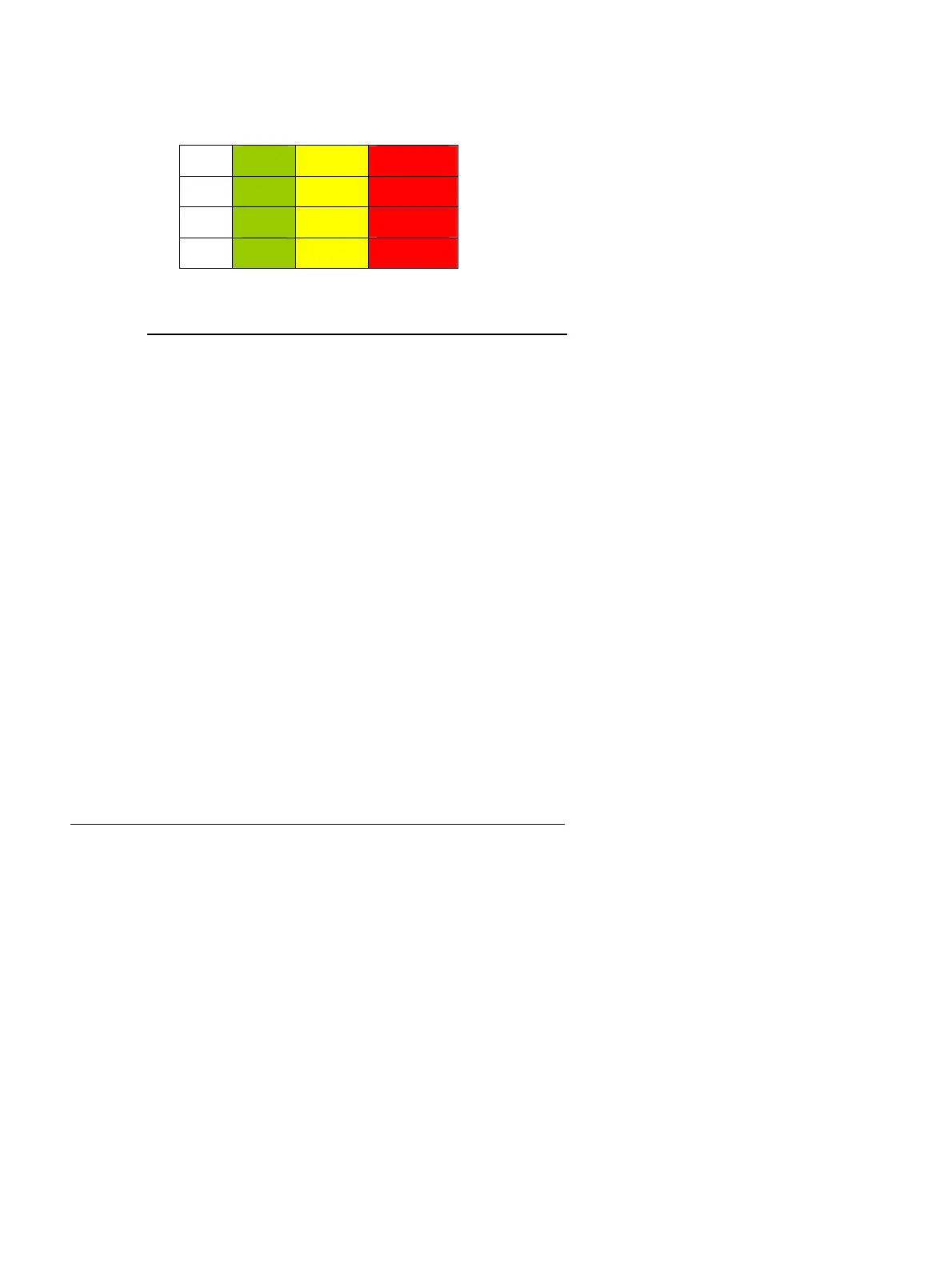

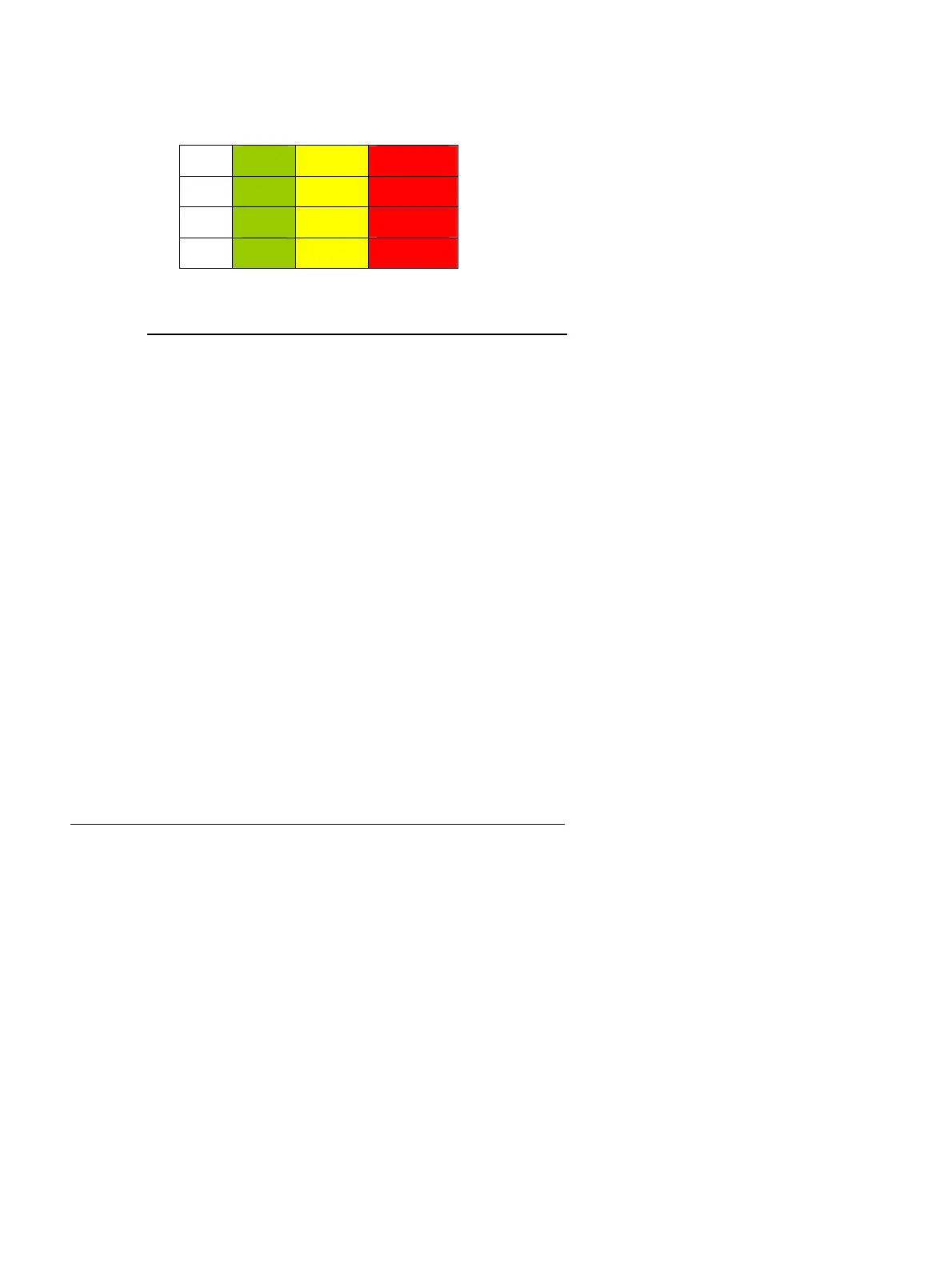

Class

OK Alert Danger

CL1 0-1 gE

1-2 gE over 2 gE

CL2 0-2 gE

2-4 gE over 4 gE

CL3 0-4 gE

4-10 gE over 10 gE

Sensor Placement Techniques

Proper hand-held sensor technique is vital to the

accuracy of Machine Condition Advisor

measurements! In general, it is critical that you

perform consistent readings.

Perform measurements with the machine operating

under normal conditions. For example, when the

machinery has reached its normal operating

temperatures and is running under its normal rated

condition (at rated voltage, flow, pressure and load).

On machines with varying speeds or loads, perform

measurements at all extreme rating conditions, in

addition to selected conditions within these limits.

When placing the sensor on the machine, generally

avoid greasy, oily, wet, or painted surfaces, housing

splits, and structural gaps. Select the best

measurement POINT (specifically avoid unloaded

bearing zones), and be consistent in sensor position,

sensor angle, and contact pressure.

Sensor Position - If possible, choose a flat surface in

the bearing’s load zone to press the sensor tip against.

Measurements should be taken at the same precise

Loading...

Loading...