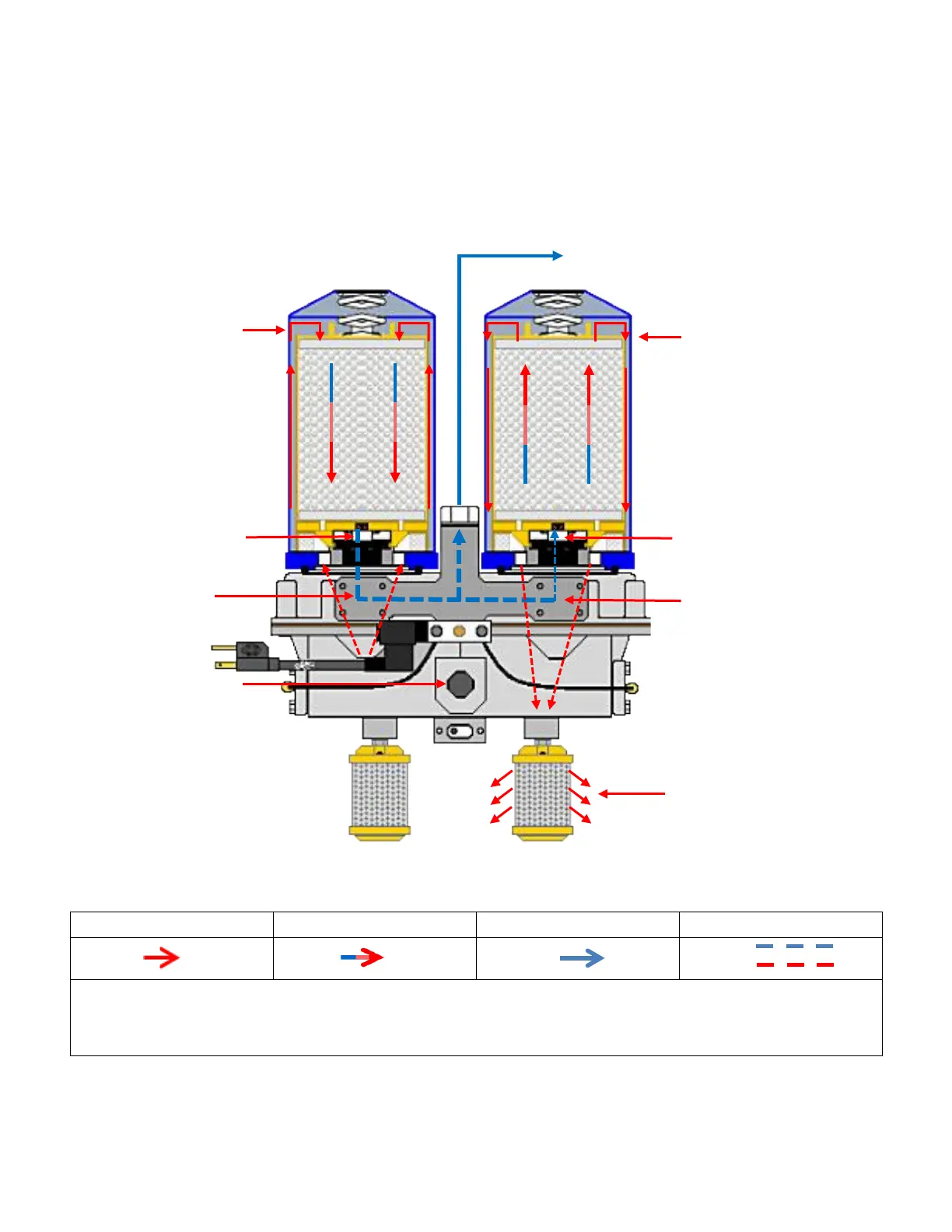

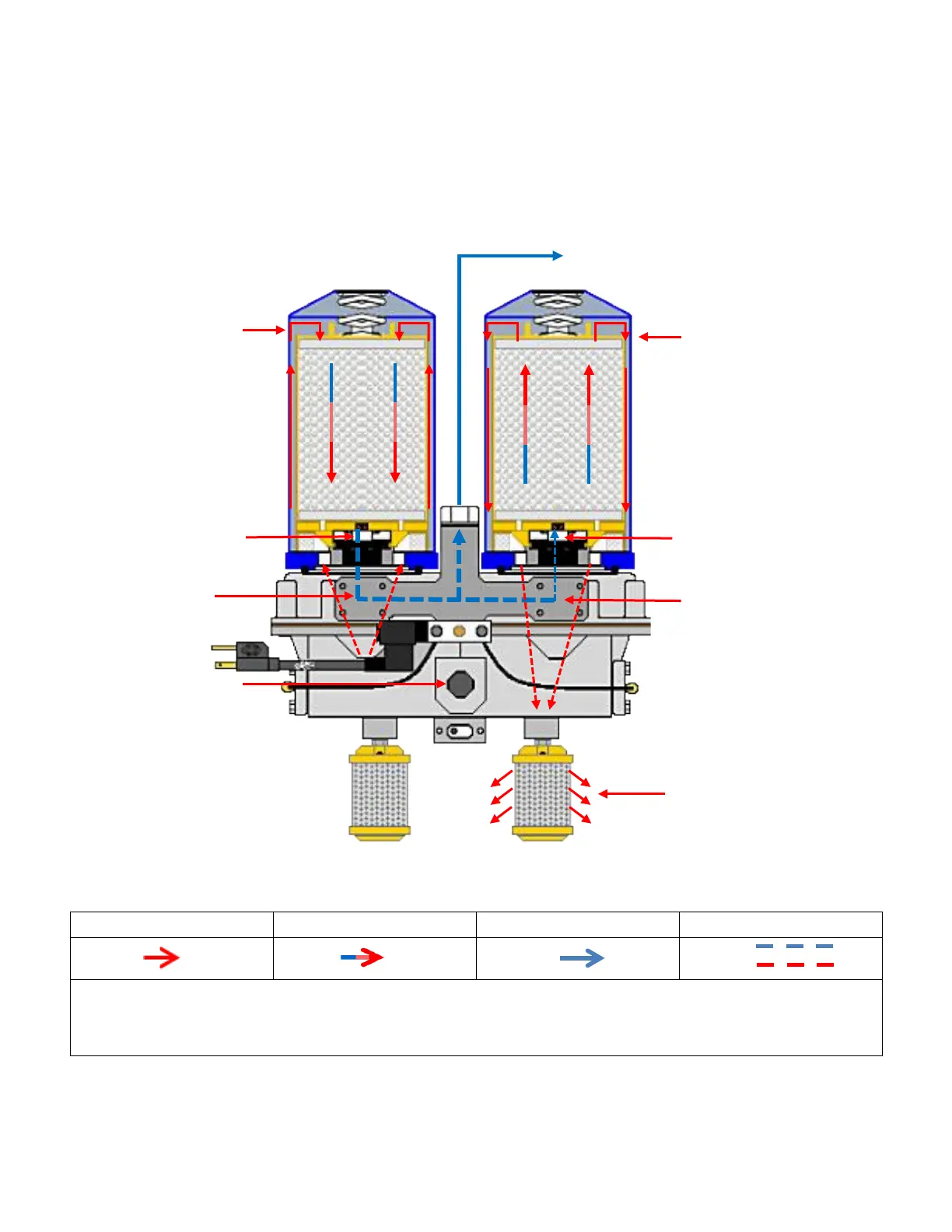

Twin Tower w/MLT

The descriptions detailed in this twin tower schematic represent the sequencing of airflow as it relates to

the actual drying process and transition - wet to dry - within all dryer systems including both

Programmable Logic (PLC) and Pneumatically Controlled (PC) systems

Total Cycle Sequence 240 sec.

Cartridge 1 receives wet air for 120 sec. while cartridge 2 regenerates for 120 for sec. - MLT switches

Cartridge 2 receives wet air for 120 sec. while cartridge 1 regenerates for 120 for sec. - MLT switches

enters dryer

4b Regen valve

"2" closed

2b Wet air removed from

"2" desiccant bed

1b Outlet Port dried air

flows to system

"1" desiccant bed

"2" desiccant bed

1b Outlet Port wet air

exhausted from dryer

2a Wet air enters

"1" desiccant bed

14

Loading...

Loading...