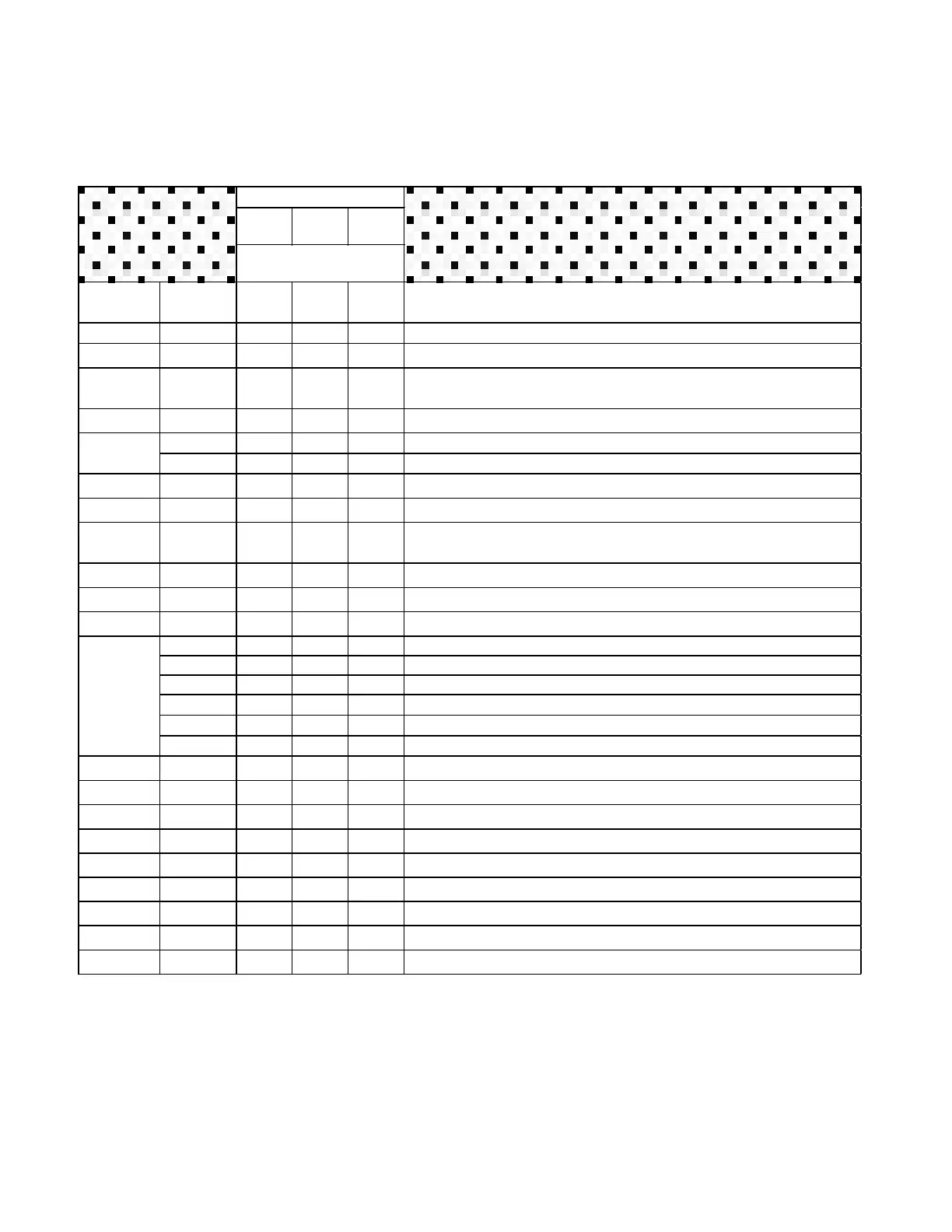

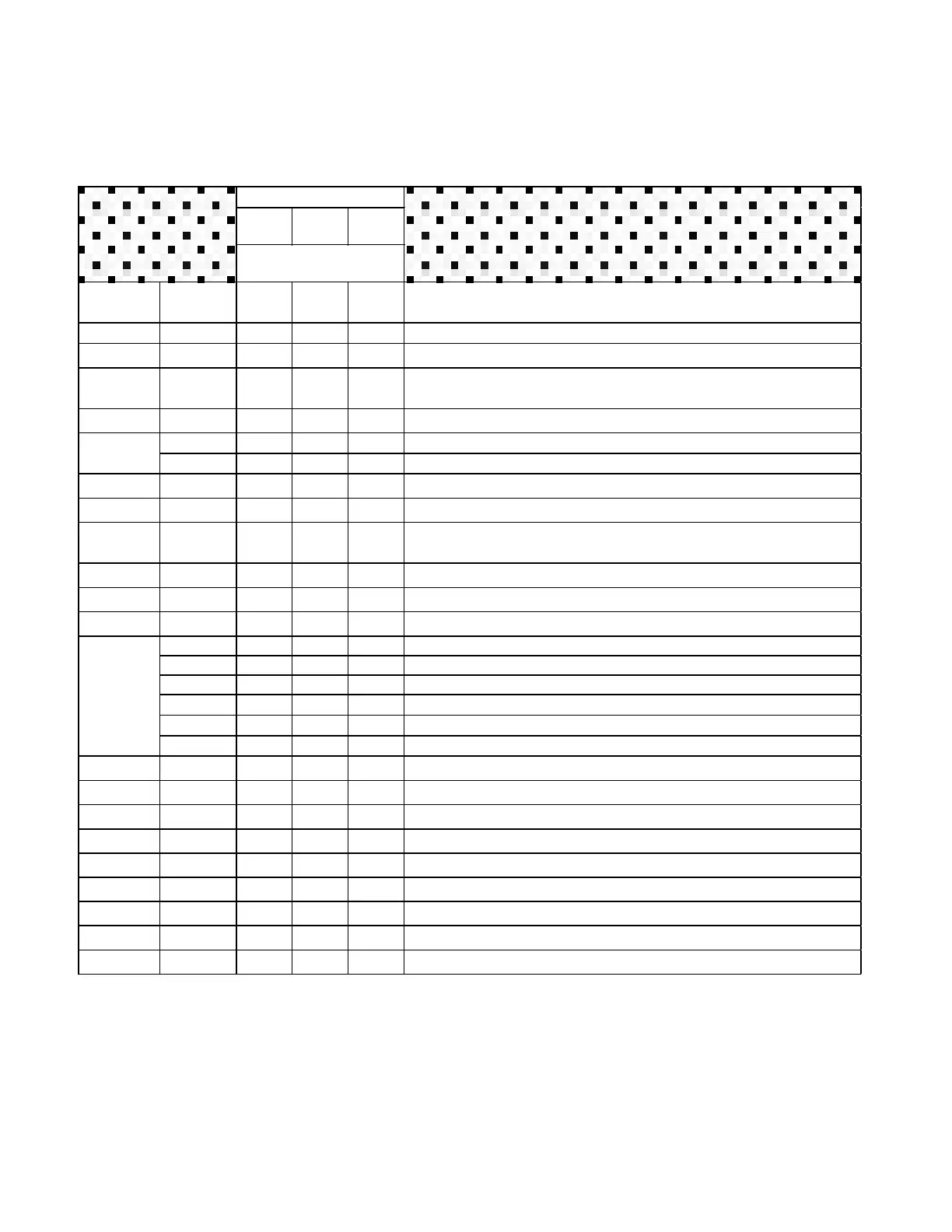

Pneumatically Controlled Applications

1. Identify dryer system by counting numbers of desiccant cartridges, e.g., 2,4,6

2. Locate service component identity, e.g., A, B, C, etc.

3. Under “Qty”, order appropriate number of kits specific to cartridge total

Full Service Kit - includes 2 cartridges, 2 inlet check valves, 2 purge

valves, 1 outlet check valve

Right hand adaptor plate with stud

Left hand adaptor plate with stud

Regeneration Valve Kit (includes 2 .030)

Regeneration Valve Kit (includes 2 .060)

Valve Service Kit - includes 2 inlet check valves, 2 purge valves, 1

outlet check valve

619985 1

- -

Pneumatic Control Valve

619987

-

1

-

Pneumatic Control Valve

619989

- -

1

Pneumatic Control Valve

619081 1

1 Max 80 cfm prefilter coalescer complete assembly

619160 1 Max 120 cfm prefilter coalescer complete assembly

619242 1

Max 200 cfm prefilter coalescer complete assembly

619245 1

1 1 Max 200 cfm prefilter coalescer complete assembly

619246 1

1 1

Max 20 cfm prefilter coalescer complete assembly

Inlet Check Valve Kit - Includes 2 inlet check valves

M 619990 1 2

3 Wall Mounting Bracket

Not Shown 619775 1

1 1 Moisture Minder (optional)

Not Shown

619942 1

- -

Wall Strut

Manifold/Mounting - two dryers (4 cartridges)

Manifold/Mounting - three dryers (6 cartridges)

21

Loading...

Loading...