BASIC OPERATION AND INSTALLATION MOUNTING INSTRUCTIONS

Micro Logic Timer (MLT) manages regeneration cycles by

energizing and de-energizing the air control valve at two-

minute intervals. However, when the air dryer is initially

powered on, the MLT begins a startup sequence of four ten-

second cycle intervals, and when completed, MLT begins

cycling every two minutes.

An LED on the MLT will be "on" during energized (charge)

cycle and "off" during de-energized (regeneration) cycle. When

LED is on, the left desiccant cartridge receives wet air and the

right desiccant cartridge regenerates. After two minutes MLT

(dryer) switches, LED is off as left canister now begins regeneration process and right desiccant cartridge

receives wet air. A light flow of air from the desiccant cartridge through dryer’s exhaust port is normal

during regeneration cycle. There should be no venting of air from desiccant cartridge when receiving wet

air.

When an SFD cycles, there will be a momentary burst of air from one SFD exhaust port (muffler). This is

normal and will occur each time dryer cycles. Four cartridge MLT systems will have two cartridges

regenerating one from each dryer unit, e.g., cartridges 1, 3 charge cycle, cartridges 2, 4 regeneration cycle

1. SFD dryer systems must be mounted with the exhaust ports positioned downward and desiccant

cartridges in upright position

2. Power source: 120 Volt AC (grounded) surge protected (recommended) electric receptacle

required for MLT and PLC dryer systems

3. Mount SFD down stream of air compressor reservoir

4. Mount SFD dryer with sufficient space around unit(s) to facilitate service and to provide visual

access for periodic inspection allowing at least a 2" clearance above desiccant cartridges for

removal

5. Installing a series of lines and shut-off valves in conjunction with installation of SFD dryer

systems provides a by-pass system providing the ability to maintain operation of air system, when

servicing unit

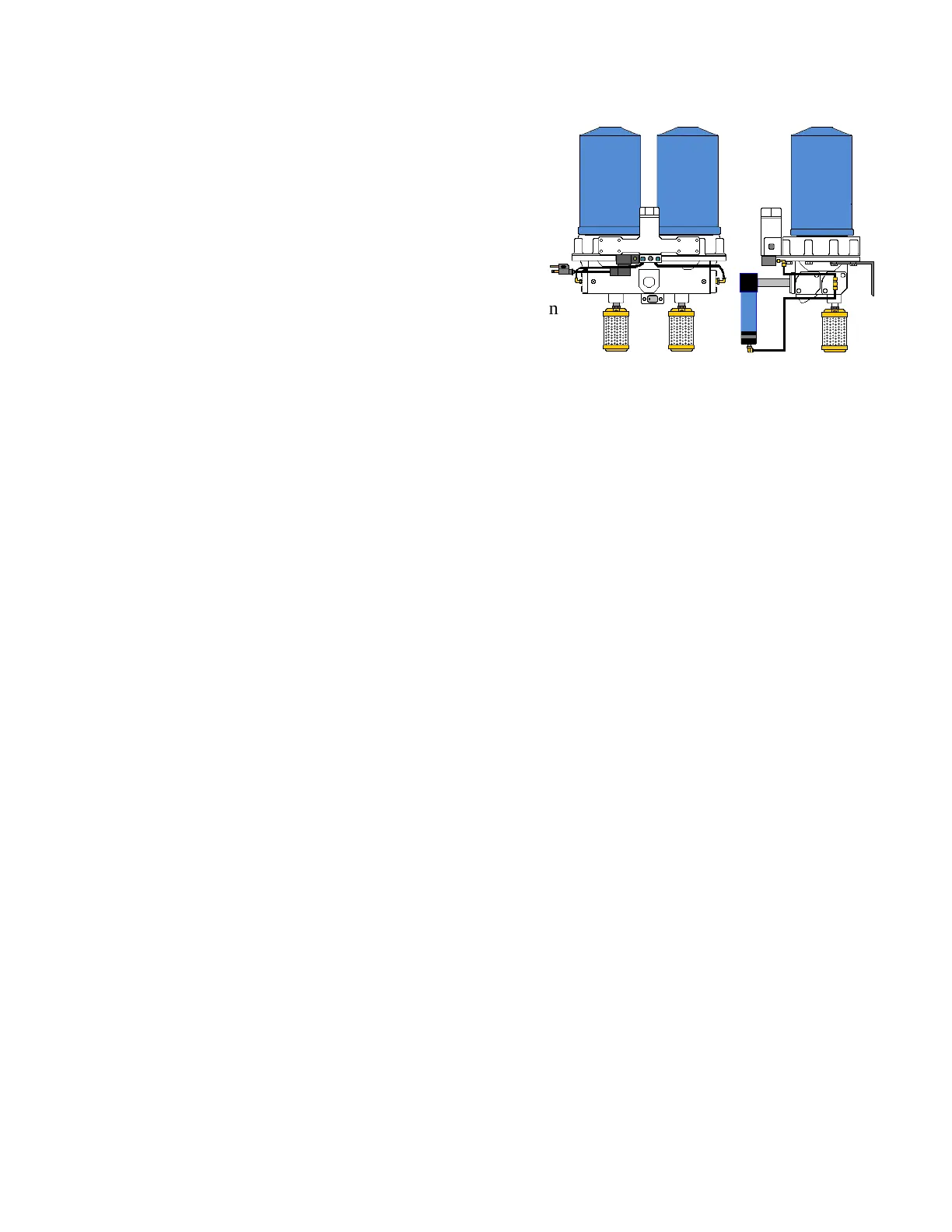

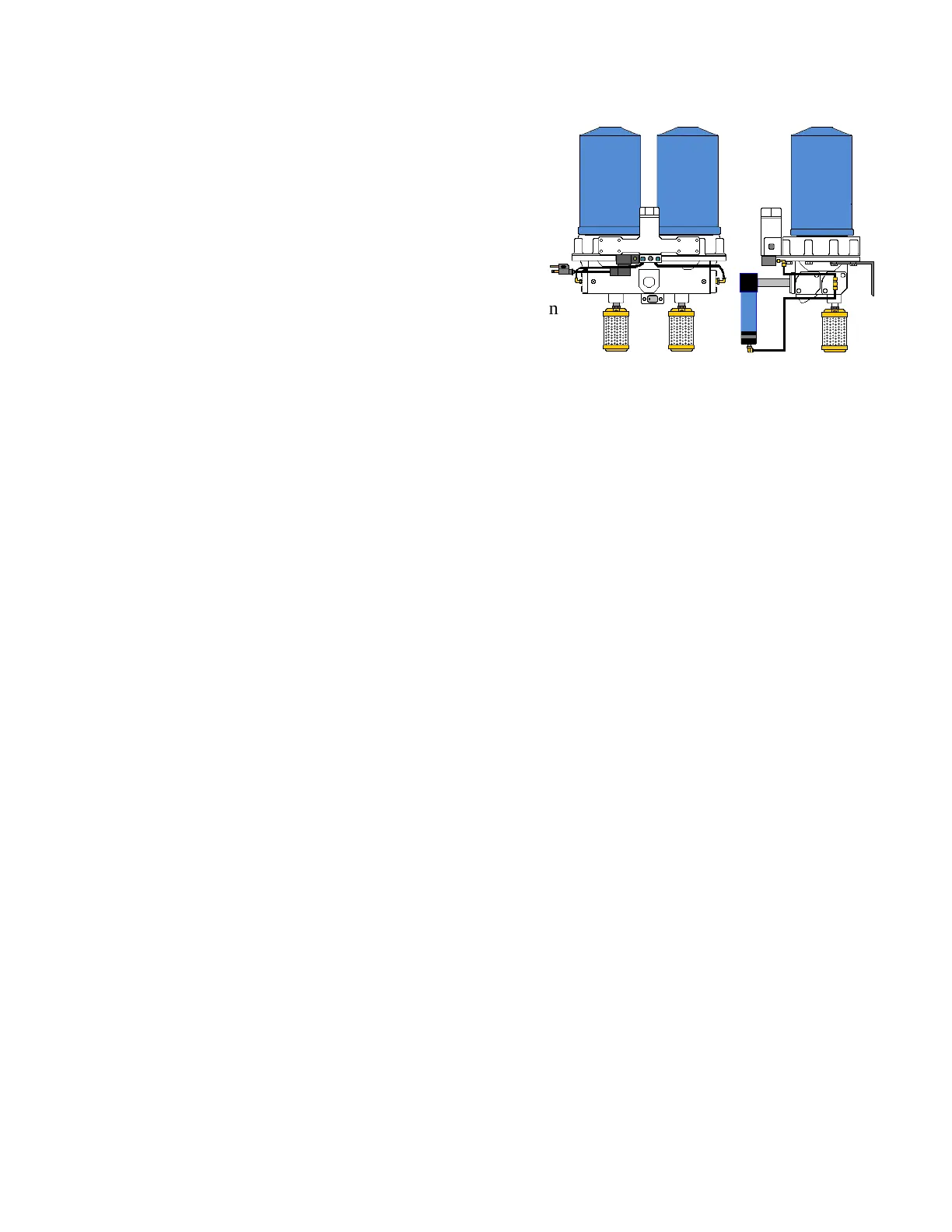

40 Max SFD Dryer Systems w/ MLT

Mounting

1. Determine proper location for SFD as described in “General Mounting Instructions” pg. 7

2. Universal mounting brackets may be inverted to adapt for mounting units as required

3. Mount base assembly at chosen location making certain a minimum 2" clearance above desiccant

cartridges for future service. Mark mounting hole locations and attach SFD to mounting location

with a minimum of two (2) 3/8” bolts, lock washers and nuts

4. Use thread sealant on air line fittings to prevent air leaks

a. Connect air line coming from compressor reservoir to SFD inlet port

b. Connect SFD outlet port to air system

5. Apply an anti-seize (included with dryer) onto muffler threads and install muffler into each

exhaust port of SFD

6. Plug-in MLT power cord to 110 -120 Volt AC grounded receptacle (surge protected

recommended) REMINDER: 12 & 24 VDC MLT’s device are polarity sensitive. MLT will not

operate if power (+) and neutral (-) leads are switched

8

Loading...

Loading...