Programmable Logic Control (PLC) Applications (120, 240 400, 600, 800 CFM Dryer Systems)

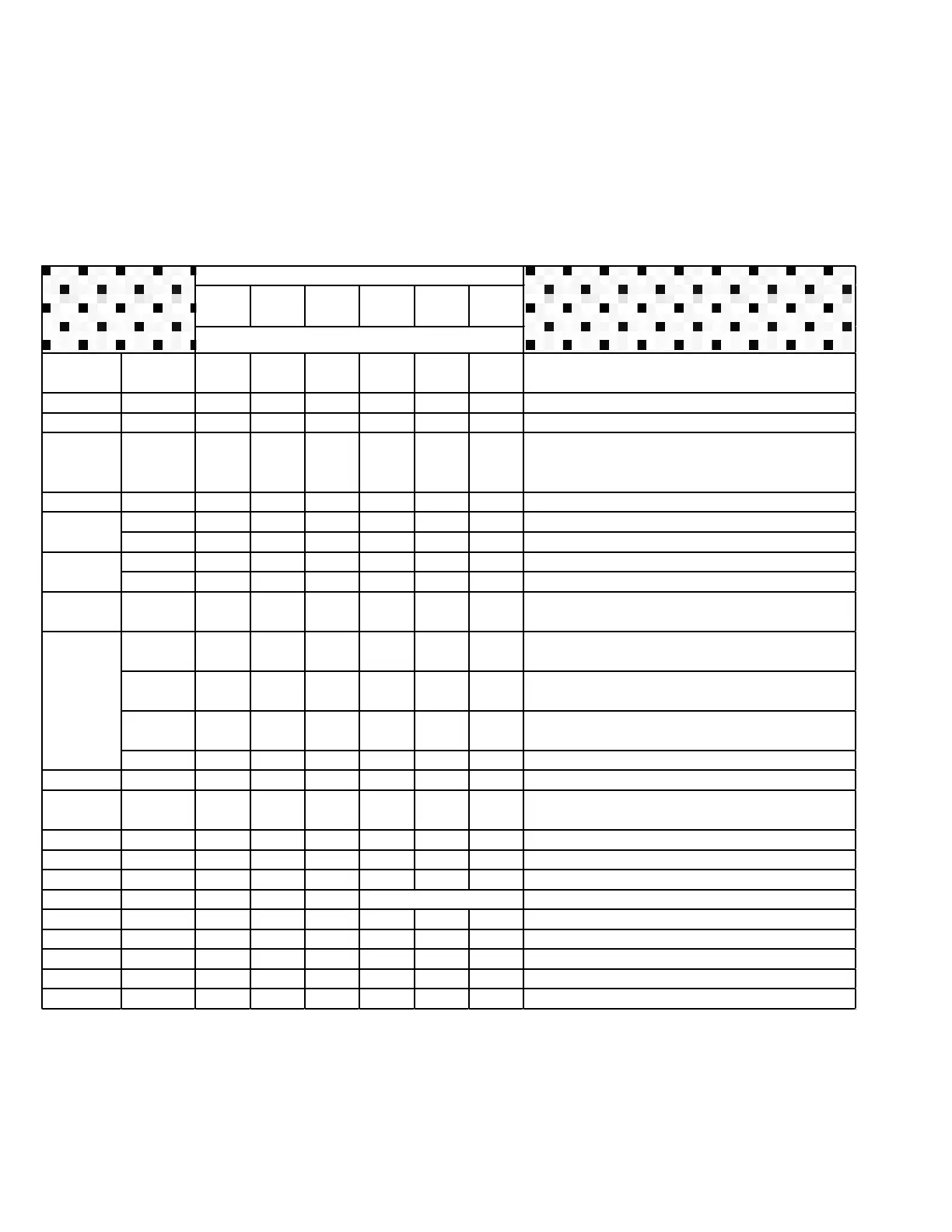

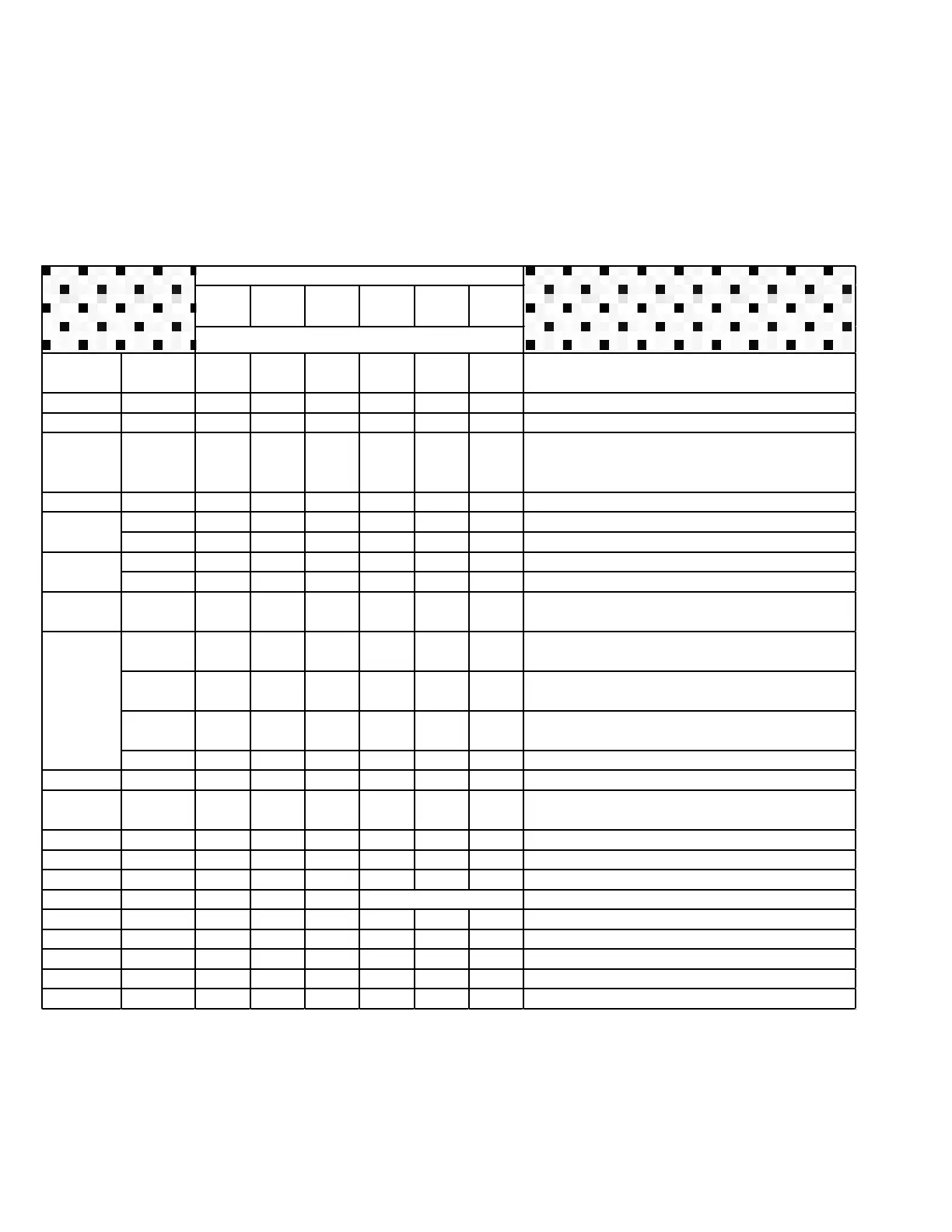

1. Identify dryer system by counting numbers of desiccant cartridges, e.g., 2, 4, 6

2. Locate service component identity, e.g., A, B, C, etc.

3. Under “Qty”, order appropriate number of kits specific to cartridge total

Qty Qty Qty Qty Qty Qty Descriptions

619704 2 3 4 6 9 12 Desiccant Cartridge Kit

A,I,J 619700 2 3 4 6 9 12

Full Service Kit - includes 2 cartridges, 2 inlet check

valves, 2 purge valves, 1 outlet check valve & 10

micron filter package

Desiccant Cartridge Kit (includes 2 cartridges

Right hand adaptor plate with stud

Left hand adaptor plate with stud

Regeneration Valve Kit (includes 2 .060)

Regeneration Valve Kit (includes 2 .090)

Valve Service Kit - includes 2 inlet check valves, 2

purge valves, 1 outlet check valve

Max 120 cfm .01 prefilter coalescer complete

assembly

Max 200 cfm .01 prefilter coalescer complete

assembly

Max 200 cfm oil coalescing .01 prefilter w/pneumatic

drain service kit

Inlet Check Valve Kit - Includes 2 inlet check valves

M 619990 2 3 4 6 12 24 Wall Mounting Bracket

Not Shown 619775 1 1 1 Moisture Minder

Manifold/Mounting - two dryers (4 cartridges)

Manifold/Mounting - three dryers (6 cartridges)

19

Loading...

Loading...