11. Reinstall 8 screws (4 on each side) and torque to 5 – 6 ft. lbs.

12. Reattach the 6 bolts through valve body into adapter plate – do not tighten

13. Reattach 2 ⅜" allen head bolts through adapter plate into valve body

14. Torque all bolts to 50 – 60 ft. lbs.

15. Reinstall both regeneration valves and springs into adapter plates

16. Install 2 new O-rings onto shoulders of manifold and install into adapter plates

17. Reinstall 8 screws (4 on each side) into manifold and torque to 5 – 6 ft. lbs.

18. Reconnect air line to outlet port of manifold

19. Slowly apply air pressure and check for leaks

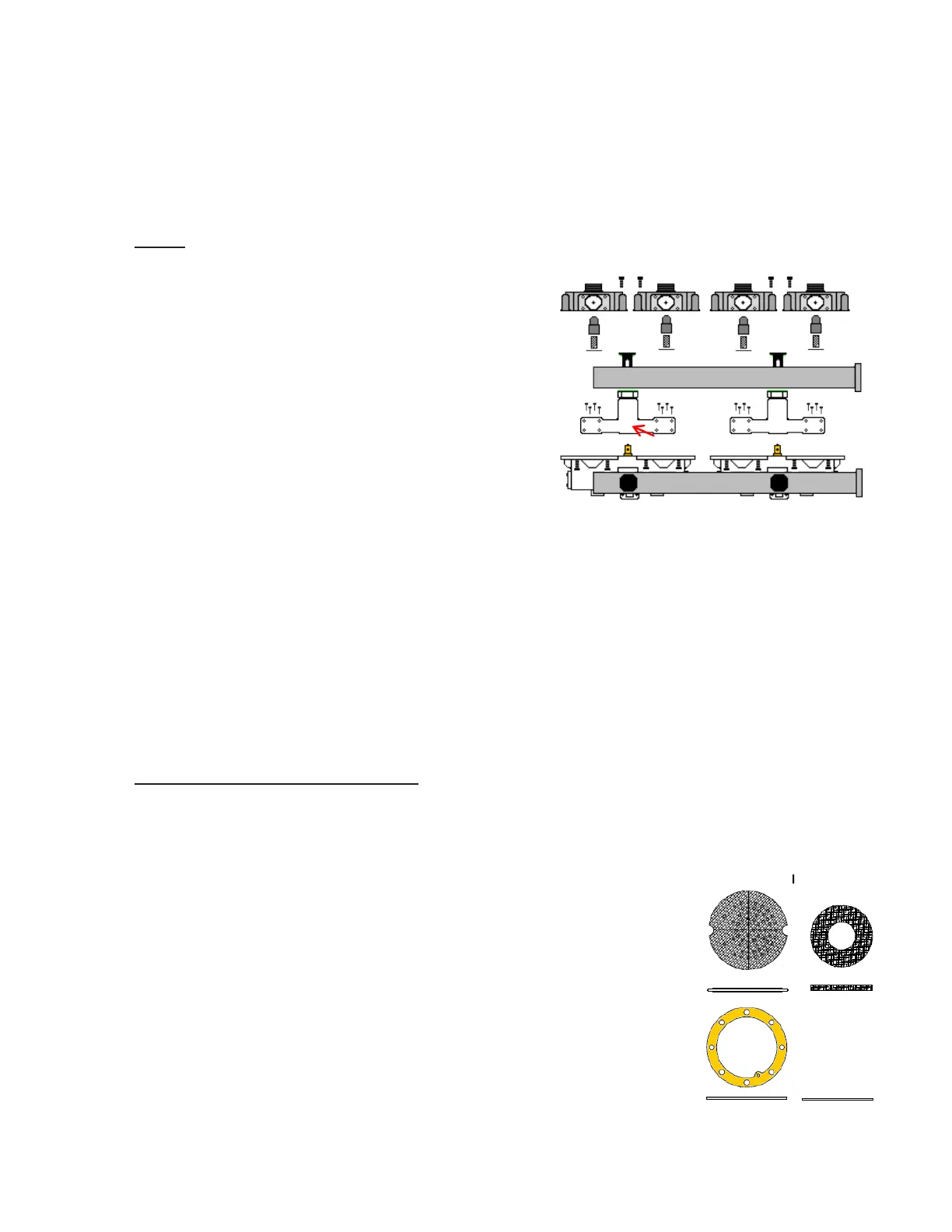

Instructions for 80- 800 cfm air dryer systems

1. WARNING: Relieve all system air pressure

2. Remove air line from outlet port manifold

3. Remove “T” bolts from outlet manifold, remove

manifold and discard green O-rings

4. Remove 8 screws (4 on each side) of dryer manifold,

remove manifold from dryer and discard O-rings

5. Remove spring and regeneration valve from defective

adapter plate and second adapter plate

6. Remove 6 - ⅜" bolts attaching defective adapter plate

to valve body

7. Remove 2 ¼” allen head bolts from top of adapter plate and remove adapter plate, gasket and/or

O-ring

8. Remove all remaining gasket material from valve housing and clean sump of valve house

9. Position gasket and/or O-ring onto valve body

10. Align adapter plate with holes onto valve body

11. Reattach the 6 bolts through valve body into adapter plate – do not tighten

12. Reattach 2 ⅜" allen head bolts through adapter plate into valve body

13. Install new O-rings onto air dryer manifold and position into adapter plates

14. Reinstall 8 screws (4 on each side) and torque to 5 – 6 ft. lbs.

15. Install a new O-ring to connections between manifold and dryer and “T” bolts and manifold

16. Torque bolts attaching new adapter plate to 50 – 60 ft. lbs

17. Torque “T” bolts to 50 – 60 ft. lbs.

18. CAUTION: Slowly pressurize system and check for any air leaks

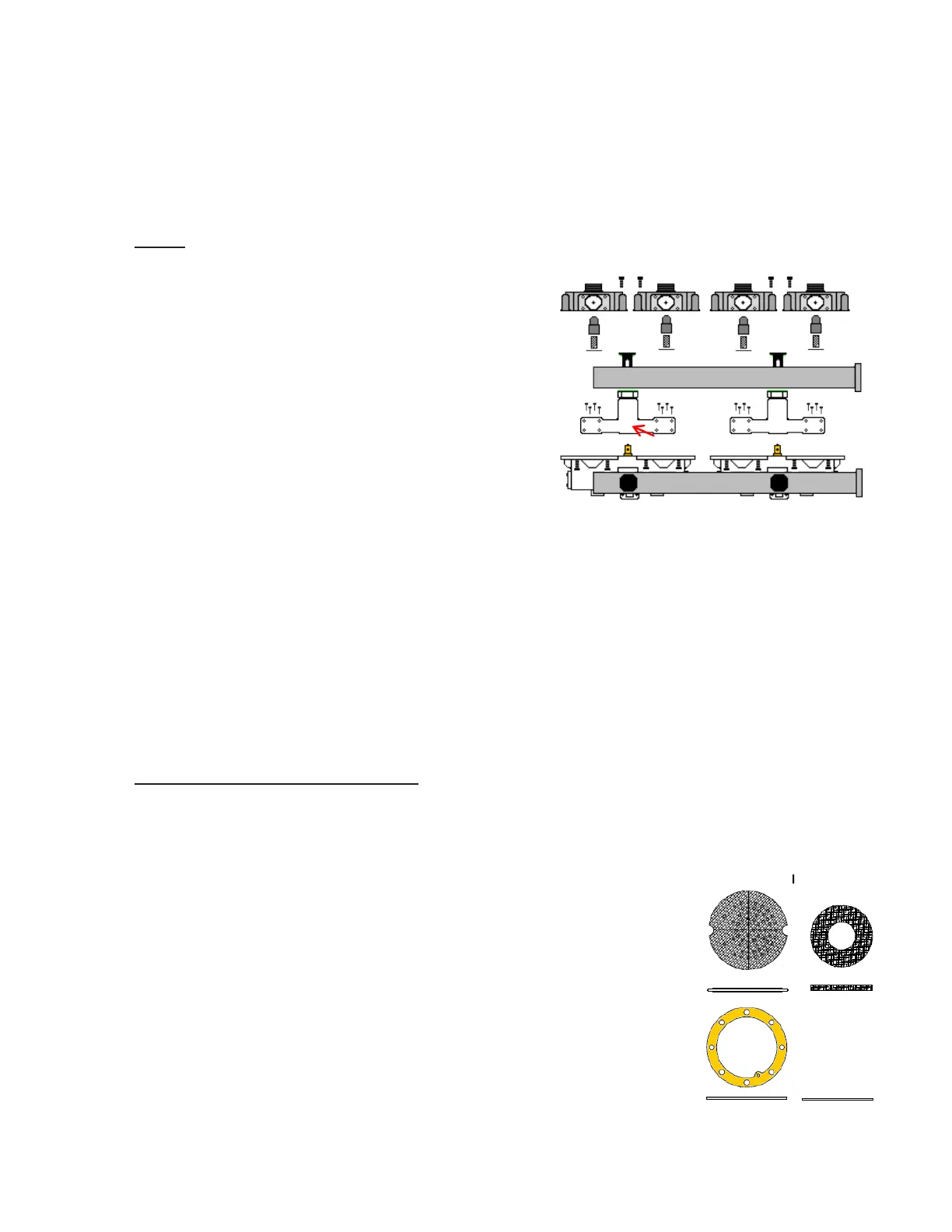

Desiccant Cartridge, Filter Pad Element and Filter Plate Replacement “F”

#619710, #619860

1. WARNING: Relieve all system air pressure

2. Disconnect air line from inlet port of dryer

3. Using a strap wrench, turn the desiccant cartridge counterclockwise,

remove, and discard

4. Remove and discard O-ring from adapter plate stud and filter elements

5. Remove four (4) 3/8" allen head bolts located at top of adapter plate

castings

6. Remove twelve (12) 3/8" hex head bolts attaching bottom valve housing

to adapter plate castings

7. Remove bottom valve housing assembly

8. Remove two filter plates, gaskets and O-rings (late model version only)

and discard

to Serial # xxxxxx

28

Loading...

Loading...