cycles pneumatically thereby cutting of continuous purge flow during compressor “off” or non-pumping

cycle.

When an SFD cycles, there will be a momentary burst of air from one SFD exhaust port (muffler). This is

normal and will occur each time dryer cycles. Four cartridge MLT systems will have two cartridges

regenerating one from each dryer unit, e.g., cartridges 1, 3 charge cycle, cartridges 2, 4 regeneration cycle

refer to pg. 15

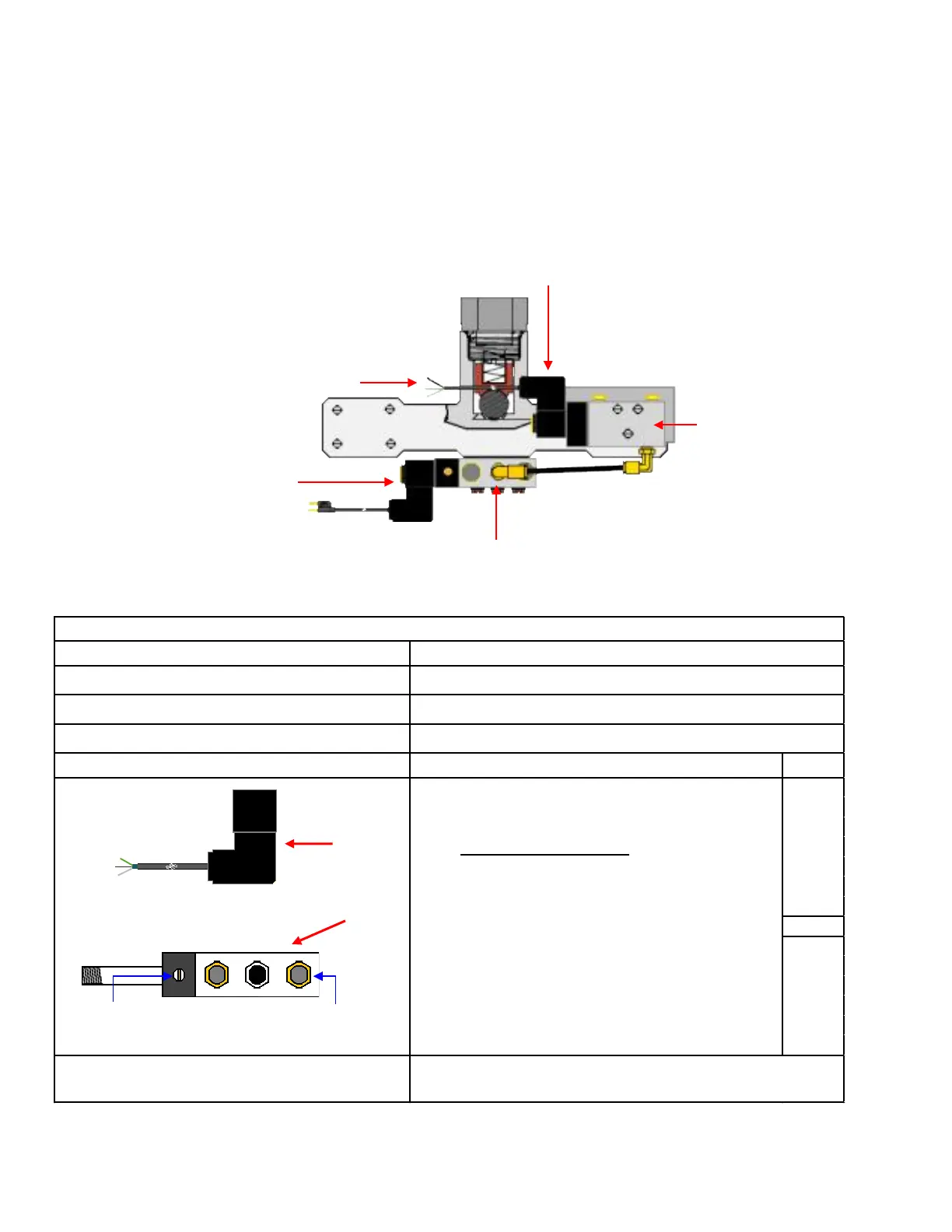

Regeneration Cutoff

Air Control Valve 1

Air Control Valve #2

Connect Wires to Air Compressor

Pressure Control Switch

Regen air does not stop when compressor pump is off

Cracked or broken pilot signal hose #1 to air control #2

Defective coil and/or air control valve

RCS and Air Control valve test procedures

Dryer does not cycle every two minutes when

compressor is on

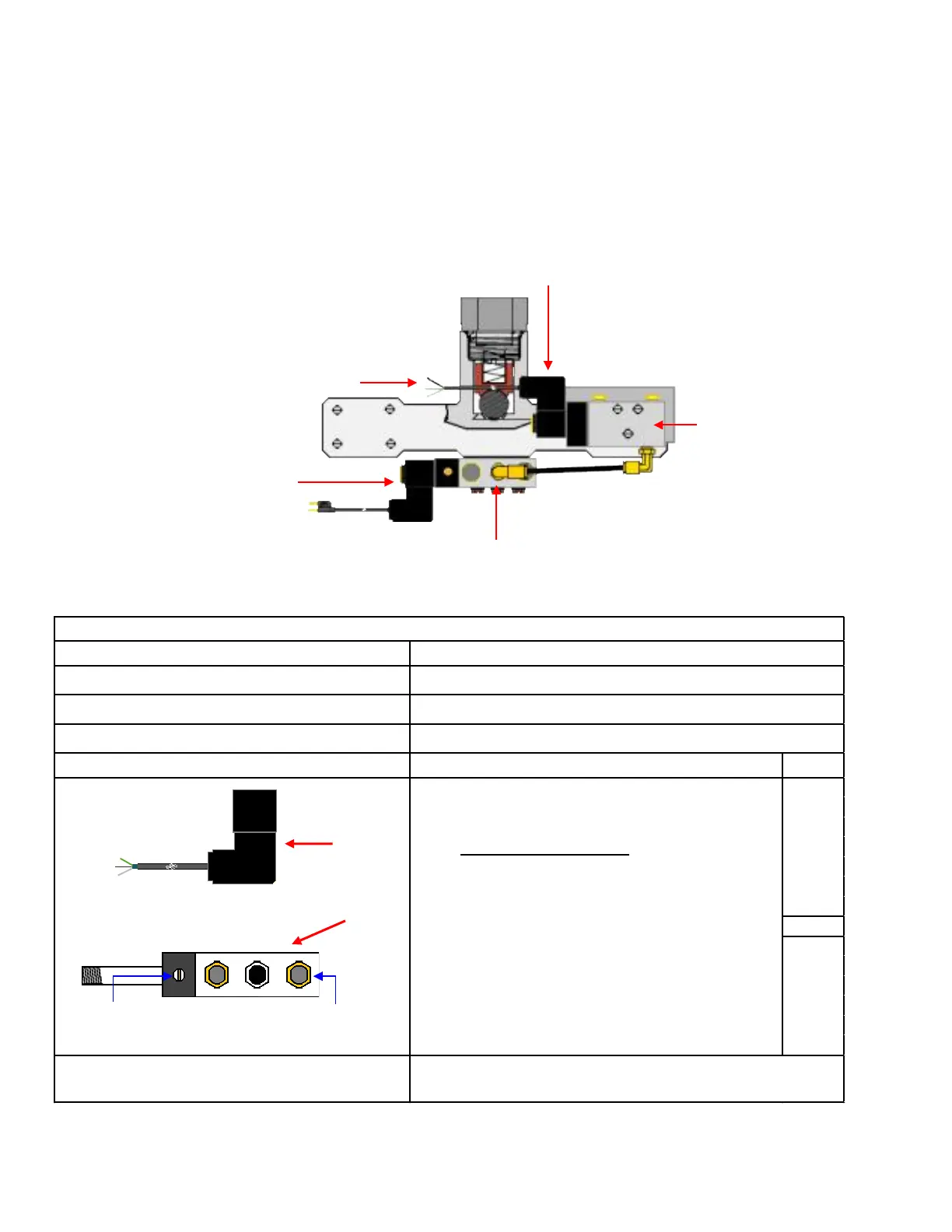

RCS (Regeneration Cutoff Solenoid)

Refer to Micro Logic Timer (MLT) section: Dryer will not cycle

(switch) every two minutes w/Micro Logic Timer on pg. 15

Step 1: Disconnect coil from air compressor pressure

control switch.

Step 2:

With compressor pumping , manually cycle air

control valve by turning brass screw in air control valve to

2

o’clock (1

/4

turn right) and back to 12

o’clock position. If

regen stops flowing, replace coil assembly "G". If regen

does not stop flowing, proceed next step

Step 3: Replace air control valve "E", reinstall RCS onto air

contol vlave and reconnect electrical connections to

pressure control switch. Note: make sure brass screw is in

12 - 6 o'clock position for normal operation

Check ekectrical connection on compressor pressure switch

Remove vents, clean and reinstall

50

Loading...

Loading...