and below work.

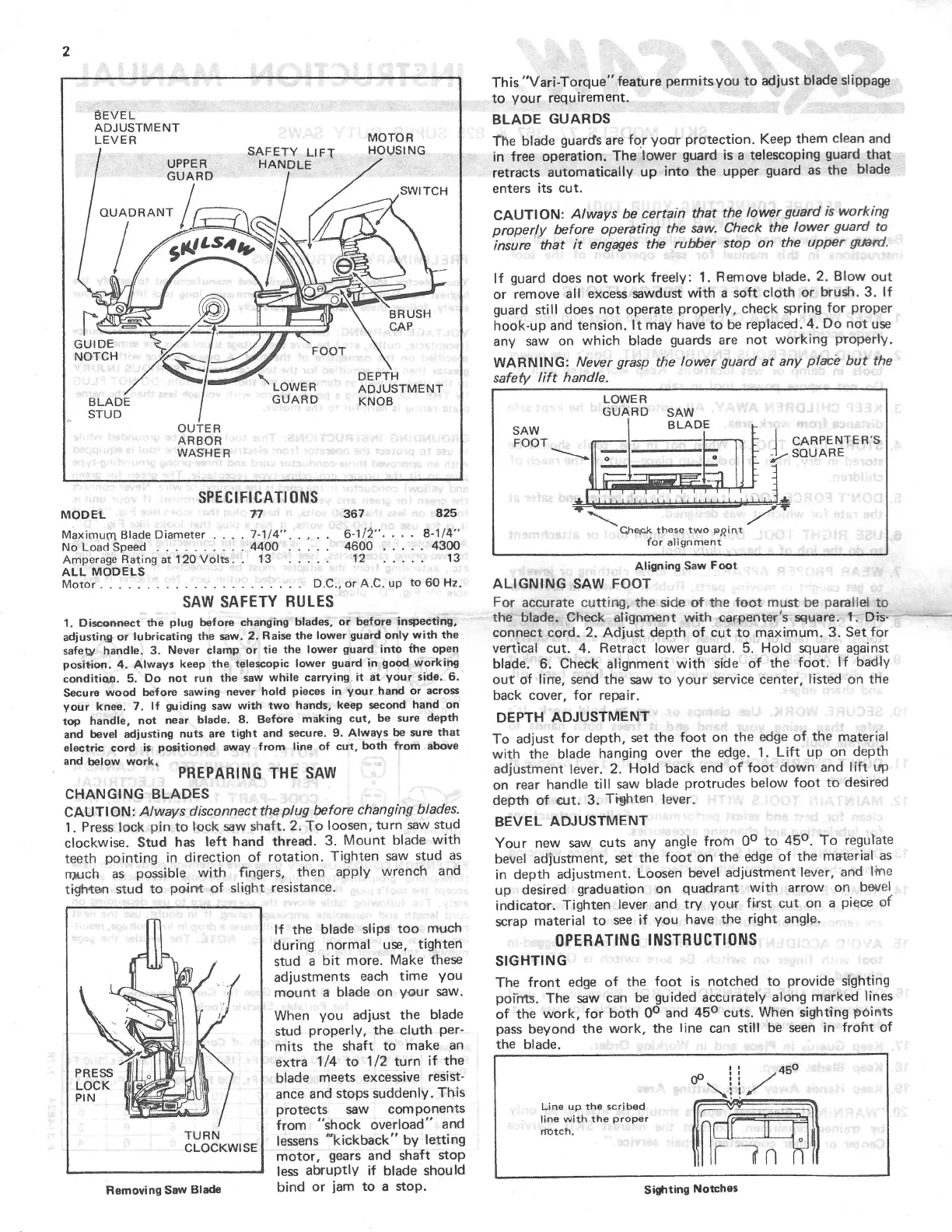

BEVEL

ADJUSTME NT

LEVER MOTOR

SAFETY LIFT HOUSING

UPPER HANDLE

GUARD

SWITCH

OUADRANT

4

\

FOOT

DEP

\

TH

LOWER ADJUSTMENT

BLADE GUARD KNOB

STUD

OUTER

ARBOR

WASHER

SPECIFICATIONS

MODEL 77 367 825

Maximum Blade Diameter

.

.

.

.

7-1/4".

.

.

.

.

6-‘l/2".

.

.

.

8-1/4"

NoLoadSpeed

. . .

. .

.

.

.

..4400

4600

.....4300

Amperage Rating

at

120’Volts.

.

13

.

. .

. .

12

.

.

.

. .

13

ALL

MODELS

Motor

.

.

. .

.

.

.

.

.

.

.

.

.

.

. .

. . . . .

.

D.C.,

or

A.C.up

to

60 Hz.

SAW SAFETY RULES

1. Disconnect

the

plug before changing blades,

or

before

inspecting,

adjusting

or

lubricating the

saw.

2. Raise the lower guard only

with

the

safety handle. 3. Never clamp

or

tie

the lower guard

into

the open

position. 4. Always keep the telescopic lower guard in good working

condition. 5. Do

not

run

the

saw

while

carryingit

at

your

side. 6.

Secure wood before sawing

never

hold pieces in

your

hand

or

across

your

knee. 7.

If

guiding

saw

with

two

hands, keepvsecond hand

on

top handle,

not

near

blade. 8. Before making cut, be

sure

depth

and bevel adjusting

nuts

are

tight and

secure.

9. Always be

sure

that

electric cord is positioned away

from

line

of

cut, both

from

above

PREPARING THE SAW

CHANGING BLADES

CAUTION: Always disconnect theplug before changing blades.

1. Press lock pin

to

lock

saw

shaft. 2. To loosen,

turn

saw

stud

clockwise. Stud has

left

hand thread. 3. Mount blade

with

teeth pointing in direction of rotation. Tighten

saw

stud as

much as possible with fingers, then apply wrench and

tighten stud

to

point

of

slight resistance.

If

the blade slips

too

much

during normal use, tighten

stud a

bit

more.

Make these

adjustments each time you

mount

a blade

on

your

saw.

When

you

adjust the blade

stud properly,

the

cluth per-

mits the shaft

to

make

an

extra

1/4

to

1/2

turn

if

the

blade meets excessive resist-

ance

and stops suddenly. This

protects

saw

components

TURN from "shock overload" and

CLOCKMSE lessens kickback by letting

motor, gears and shaft stop

less abruptly

if

blade should

Removing saw Blade bind

or

jam

to

a stop.

This "Vari-Torque" feature permitsyou

to

adjust blade slippage

to

your

requirement.

BLADE GU AR DS

The blade guards

are

for

your

protection. Keep them clean and

in free operation. The lower guard is a telescoping guard that

retracts

automatically up into the upper guard

as

the blade

enters

its

cut.

CAUTION: Always be certain that the lower guard is working

properly before operating the

saw.

Check the lower guard

to

insure that

it

engages the rubber stop

on

the

upper

gt/am’.

If

guard does

not

work freely: 1. Remove blade. 2. Blow

out

or

remove

all

excess

sawdust with a soft cloth

or

brush. 3.

If

guard still does

not

operate properly, check spring

for

proper

hook-up and tension.

It

may have

to

be replaced. 4. Do

not

use

any

saw

on

which blade guards

are

not

working properly.

WARNING: Never grasp the lower guard

at

any place

but

the

safety

lift

handle.

LOWER

GUAR D SAW

BLADE

SAW

FOOT I CARPENTEITS

;/

SQUARE

Qheic.l< these

two

ppint

for

alignment

Aligning Saw Foot

ALIGNING SAW FOOT

For

accurate

cutting, the side

of

the

foot

must

be parallel

to

the blade. Check alignment

with

carpenter's square. 1. Dis-

""-*-—-

connect

cord. 2. Adjust depth of

cut

to

maximum. 3. Set for

vertical

cut.

4. Retract lower guard. 5. Hold square against

blade. 6. Check alignment with side of the

foot.

If

badly

out

of line, send the

saw

to

your

service center, listed

on

the

back cover,

for

repair.

DEPTH ADJUSTMENT

To adjust

for

depth, set the

foot

on

the edge of the material

with

the blade hanging

over

the edge. 1.

Lift

up

on

depth

adjustment lever. 2. Hold back end of‘

foot

down and

lift

up

on

rear

handle

till

saw

blade protrudes below

foot

to

desired

depth of

cut.

3. Tighten lever.

’

BEV EL ADJUSTMENT

Your

new

saw

cuts

any angle from 0°

to

45°. To regulate

bevel adjustment, set the

foot

on

the edge of the material as

in depth adjustment. Loosen bevel adjustment lever, and line

up desired graduation

on

quadrant

with

arrow

on

bevel

indicator. Tighten lever and try

your

first

cut

on

a piece of

scrap material

to

see

if

you have the right angle.

OPERATING INSTRUCTIONS

SIGHTING

The front edge of the foot is notched

to

provide sighting

points. The

saw

can

be guided accurately along marked lines

of

the work,

for

both 0° and 45°

cuts.

When sighting points

pass beyond the work, the line

can

still be

seen

in

froht

of

the blade.

Line

up

the

scribed

line

with

the

proper

match.

Sighting Notches

Loading...

Loading...