SKYJACK, Page 32

February 2008

Mid Size & Full Size RT’s

Engine Powered

Section 2 - Operation Visual and Daily Maintenance Inspections

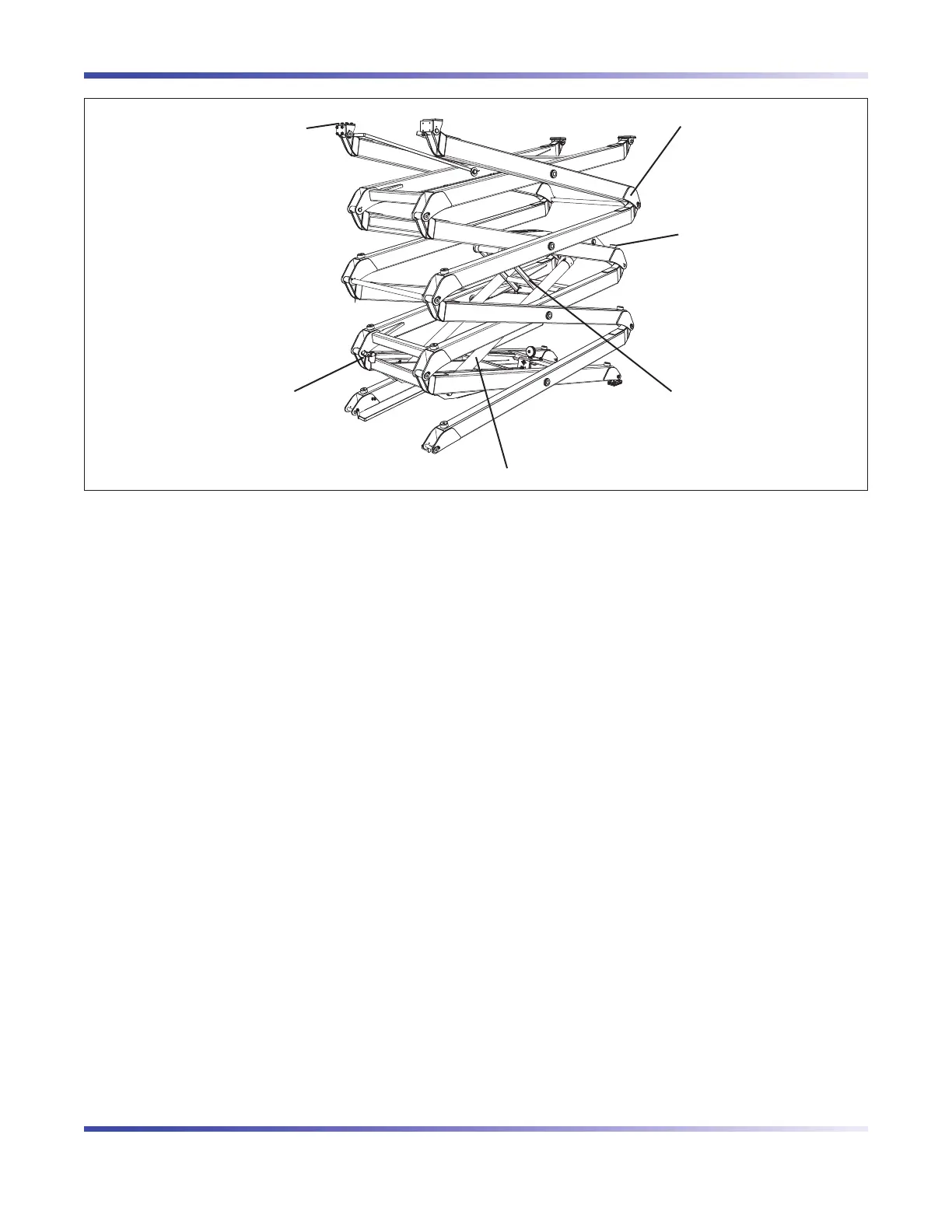

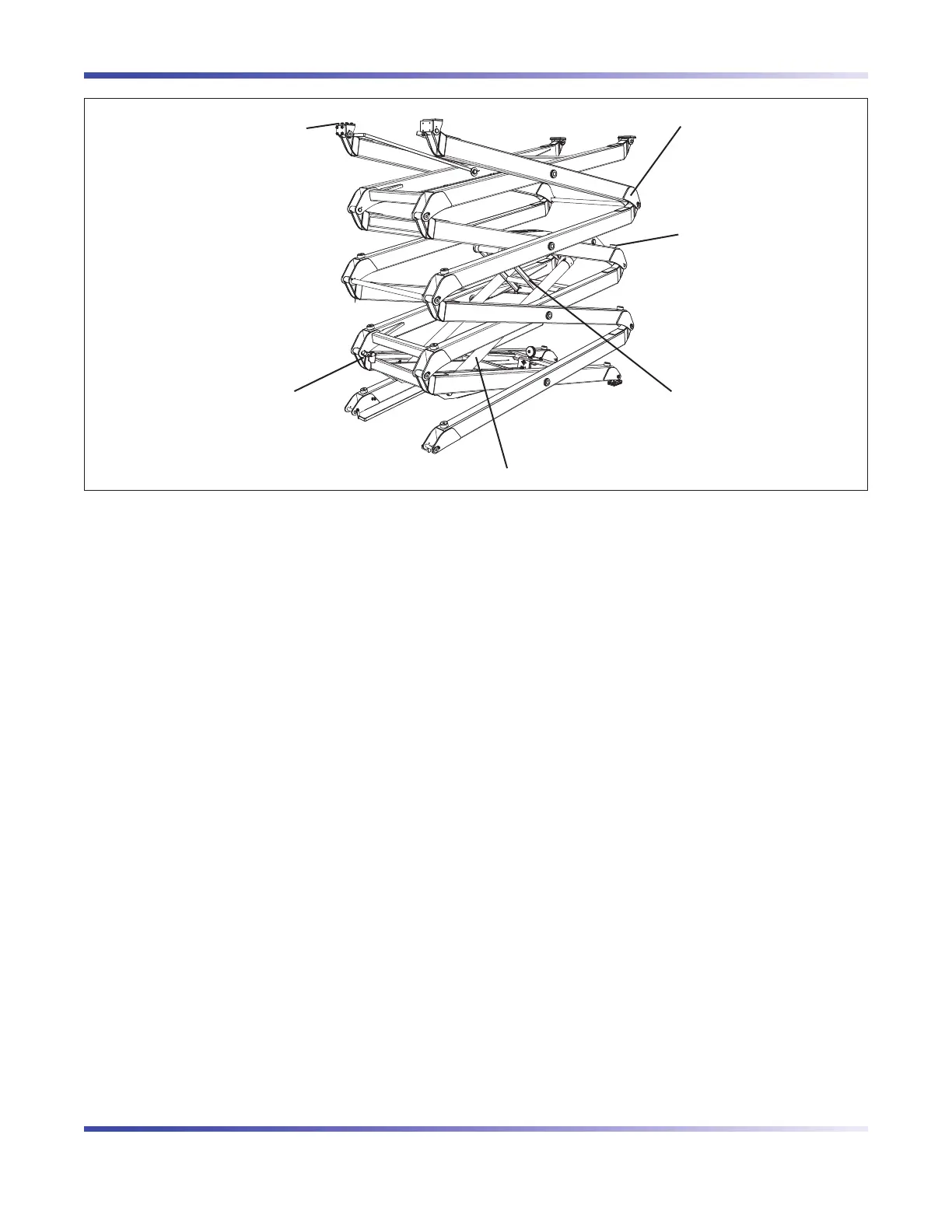

2.8-9 Lifting Mechanism

Scissor Guards•

Ensure there are no loose or missing -

parts and there is no visible damage.

Sliders•

Ensure sliders are secure and there is no -

visible damage.

Ensure sliders’ path of travel are free from -

dirt and obstructions.

1. Raise the platform (refer to Section 2.10-2)

until there is adequate clearance to swing

down the maintenance support (refer to

Section 2.16).

Maintenance Support•

Ensure maintenance support is properly -

secured and shows no visible damage.

Scissor Assembly•

Ensure scissor assembly shows no visible -

damage and no signs of deformation in

weldments.

Ensure all pins are properly secured. -

Ensure cables and wires are properly -

routed and shows no signs of wear and/

or physical damage.

Scissor Bumpers•

Ensure bumpers are secure and shows -

no sign of visible damage.

Lift Cylinder(s)•

Ensure each lift cylinder is properly -

secured, there are no loose or missing

parts and there is no evidence of

damage.

Ensure all fittings and hoses are properly -

tightened and there is no evidence of

hydraulic leakage.

2. Raise the platform until there is adequate

clearance to swing up the maintenance

support into storage bracket. Refer to

Section 2.16.

3. Fully lower the platform.

Scissor Assembly

Maintenance

Support

Lift Cylinder

Scissor Bumper

Slider

Limit Switch

Loading...

Loading...