INTRODUCTION

8

The capacitive leakage is an inherent characteristic of the device controlled primarily by

design details. The resistive leakage is a characteristic of insulating materials used and the

amount of resistive leakage is generally an indication of the quality of the insulation. This

is particularly true when identical devices are being comparatively tested. Both capacitive

and resistive leakages vary, almost linearly, with the applied test voltage.

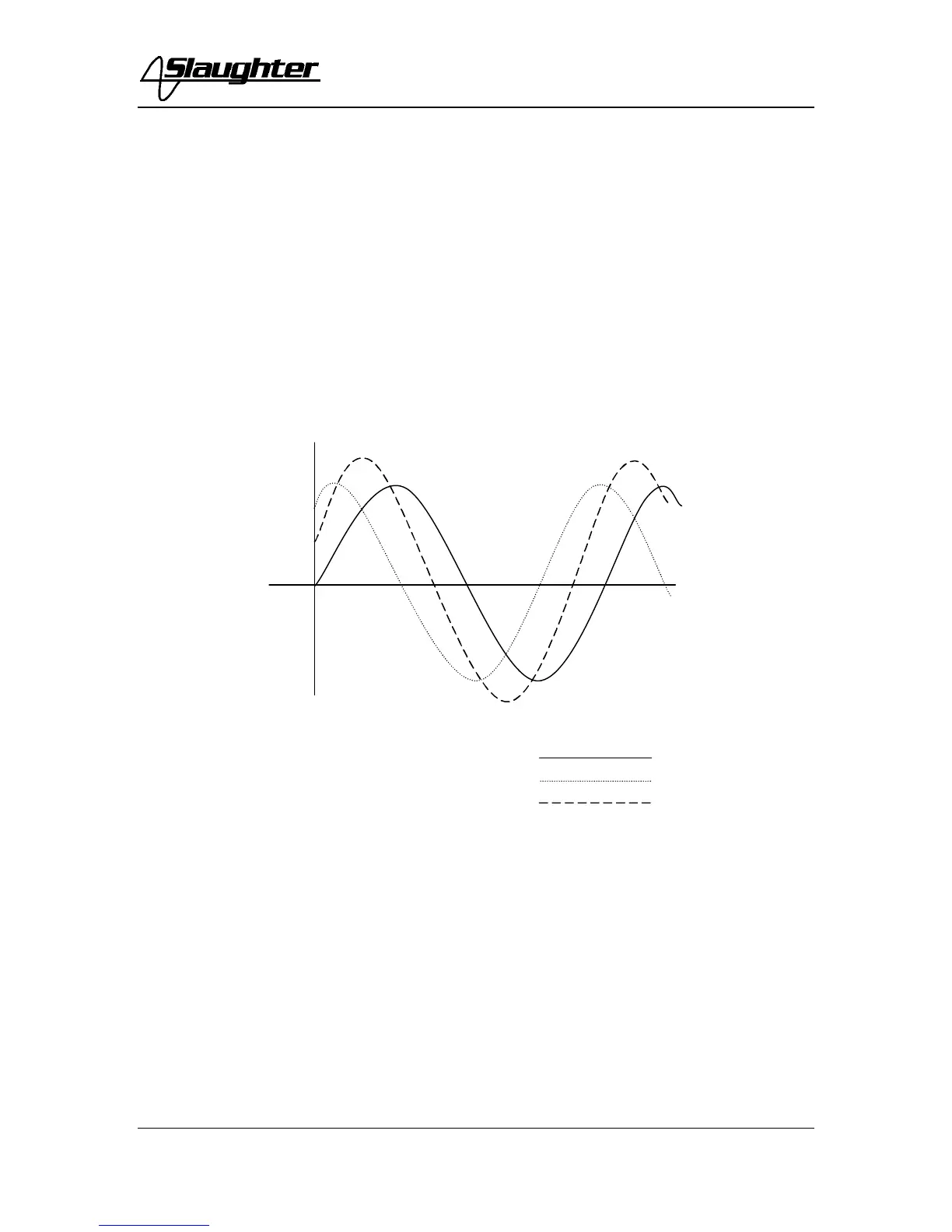

In the average electrical device during AC hipot tests, the resistive current flow is

normally much smaller than the capacitive current flow, so changes in the resistive current

do not have a significant effect on the total current. The capacitive current, however, is

out of phase with the resistive current and can be cancelled in the measurement (figure 2.).

With this type of test arrangement, the masking effect of the capacitive current is greatly

reduced or eliminated and small variations in insulation resistance become detectable.

RESISTIVE CURRENT

CAPACITIVE CURRENT

TOTAL CURRENT

figure 2.

Breakdown is also a flow of current. However the term is usually used to denote an

actual insulation failure. It is readily distinguishable from leakage because the current does

not vary linearly with the applied voltage, but instead rises suddenly when the critical or

breakdown voltage is reached. Often, but not always, arcing is associated with

breakdown.

Arcing occurs in solids and liquids as well as gases. Arcing typically involves currents on

the order of 0.4 amperes or more and indicates a potentially dangerous breakdown of

insulation or abnormal current flows inside a device.

Loading...

Loading...