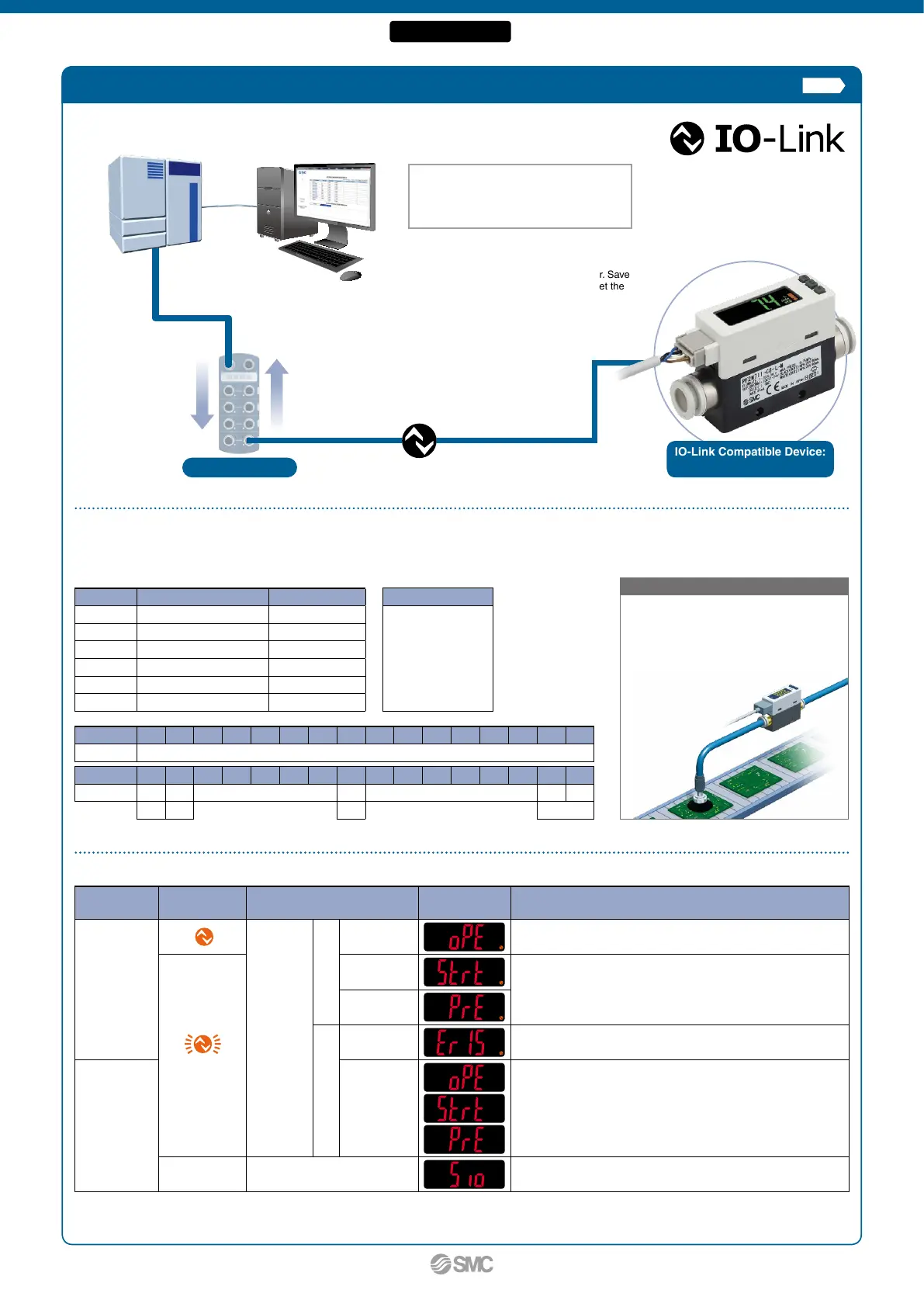

Implement diagnostic bits in the process data.

Supports the IO-Link communication protocol

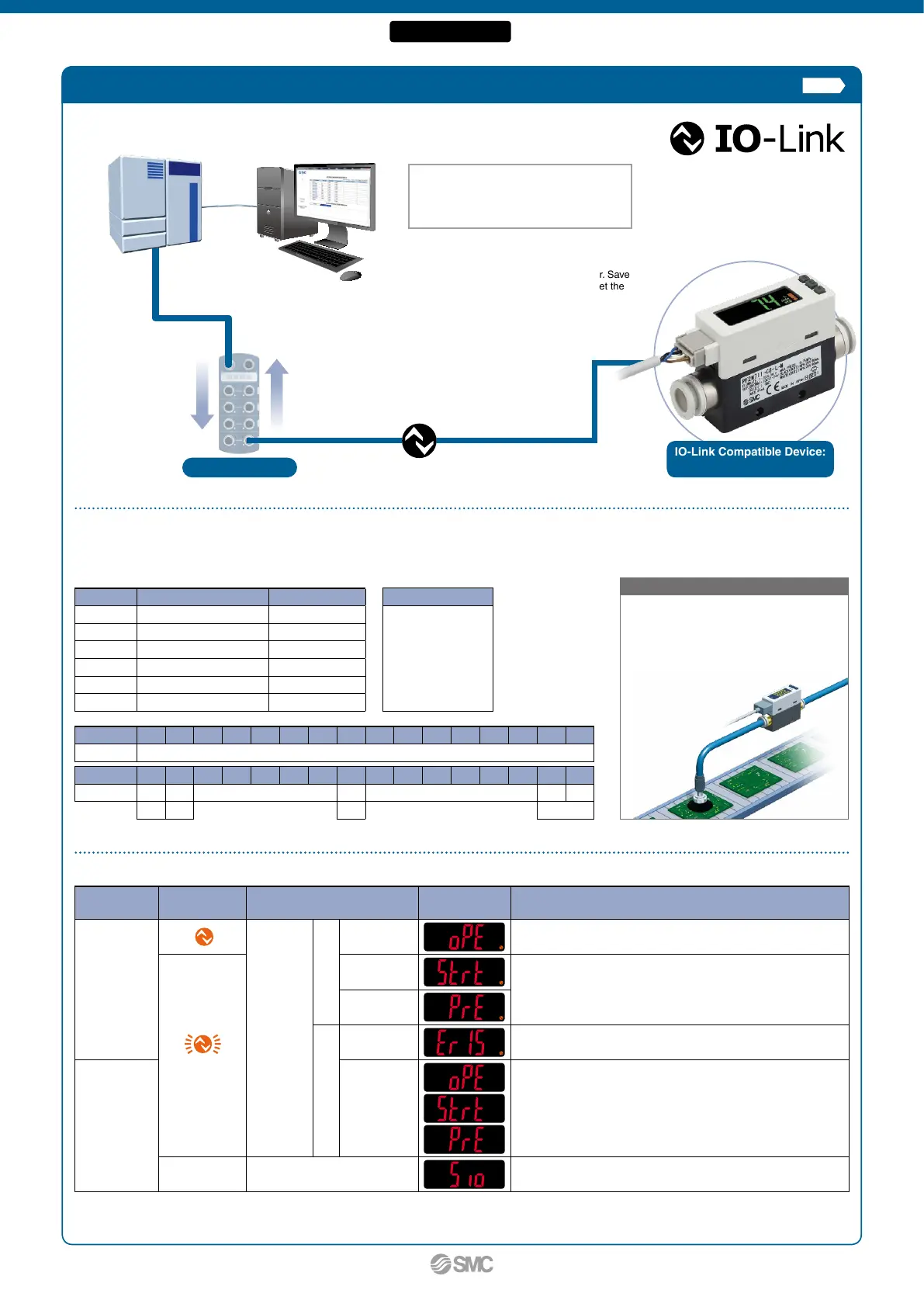

IO-Link is an open communication

interface technology between the sensor/

actuator and the I/O terminal that is an

international standard: IEC61131-9.

IO-Link Master

Device settings

can be set by the

master.

• Threshold value

• Operation

mode, etc.

Read the device data.

• Switch ON/OFF signal and analog value

•

Device information:

Manufacturer, Product part number, Serial number, etc.

• Normal or abnormal device status

• Cable breakage

Application Example

Configuration File (IODD File

*

1

)

· Manufacturer · Product part no.

· Set value

*1 IODD File:

IODD is an abbreviation of IO Device

Description. This file is necessary for setting

the device and connecting it to a master. Save

the IODD file on the PC to be used to set the

device prior to use.

For the predictive maintenance of

suction verification

The flow rate “switch ON/OFF signals” and

“analog values” are monitored to determine

the suction status. The process and

suction status can then

be compared.

IO-Link Compatible Device:

Digital Flow Switch

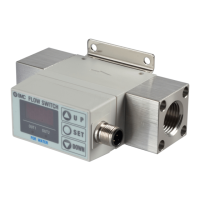

Operation and Display

Communication

with master

IO-Link status

indicator light

Status

Screen display

*

2

Description

Ye s

*

1

IO-Link

mode

Normal

Operate Normal communication status (readout of measured value)

*

1

(Flashing)

Start up

At the start of communication

Preoperate

Abnormal

Version does

not match

The IO-Link version does not match that of the master.

The master uses version 1.0.

No

Communication

disconnection

Normal communication was not received for 1 s or longer.

OFF SIO mode

General switch output

*1 In IO-Link mode, the IO-Link indicator is ON or flashing.

*2 “LoC” is displayed when the data storage lock is enabled. (Except for when the version does not match or when in SIO mode)

The display color can be set to red or green.

Diagnosis items

· Over current error

· Outside of rated flow

range

· Accumulated flow

error

· Internal product

malfunction

Process Data

Bit offset Item Note

0 OUT1 output 0: OFF 1: ON

1 OUT2 output 0: OFF 1: ON

8 Diagnosis (flow rate) 0: OFF 1: ON

14 Fixed output 0: OFF 1: ON

15 Diagnosis (error) 0: OFF 1: ON

16 to 31 Measured flow rate value Signed 16 bit

Bit offset 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

Item Measured flow rate value (PD)

Bit offset 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Item

Error Fixed

Reservation

Flow rate

Reservation

OUT2 OUT1

Diagnosis

Output

Diagnosis

Switch output

The diagnostic bit in the cyclic process data makes it easy to find problems with the equipment.

It is possible to find problems with the equipment in real time using the cyclic (periodic) data and to monitor such problems in detail with the noncyclic (aperiodic) data.

p. 10

Fieldbus

PLC

PC

IO-Link Compatible PF2M7mm-m-Lm-mmm

4

2-Color Display

Digital Flow Switch PF2M7(-L) Series

Loading...

Loading...