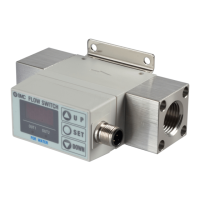

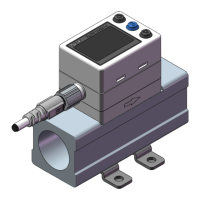

How to fix SMC Networks Switch when display is off?

- MMichael HarrisonAug 16, 2025

If the display of your SMC Networks Switch is off, it could be due to a wiring failure or a loose connector. Correct the wiring or check the connector to resolve the issue.