1. Turn the machine on “l” using the switch C . The warning

lamp D will light to indicate that the machine is on.

2. Press the torch trigger briefly to open the flow of compressed

air. Since the arc is not lit, air leaves the torch for only 5 sec.

3. Now adjust the pressure, shown on the pressure gauge F

to 4.7 bar or 68 psi Lift the knob to adjust. Clockwise will

increase and counterclockwise will decrease. Then lock the

knob by pressing it downward.

4. Connect the grounding clamp to the work piece. The cutting

circuit must not be deliberately placed in direct or indirect

contact with the protective wire except in the work piece.

If the work piece is deliberately grounded using the

protective conductor, the connection must be as direct as

possible and use a wire of at least the same size as the

cutting current return wire, and connected to the work piece

at the same point as the return wire using the return wire

clamp or a second grounding clamp placed in the immediate

vicinity. Every precaution must be taken to avoid stray

currents.

5. Use the knob M to adjust the cutting current from 20 to 55A

based on the work at hand. Use a 0.9mm nozzle up to 35A

and a 1.1mm nozzle for 35-55A. Be sure to use the two-point

spacer (PLASMA2504) with the 1.1mm nozzle.

6. Make sure that the ground clamp and the work piece are in

good electrical contact, especially with painted or oxidized

metal or with insulated coating; connect the clamp as close

as possible to the cutting area.

Do not connect the grounding clamp to the part of the

material that is to be removed.

7. Press the torch trigger to strike the pilot arc. If cutting does

not begin within 2 seconds, the pilot arc goes out; press the

trigger again to re-strike it.

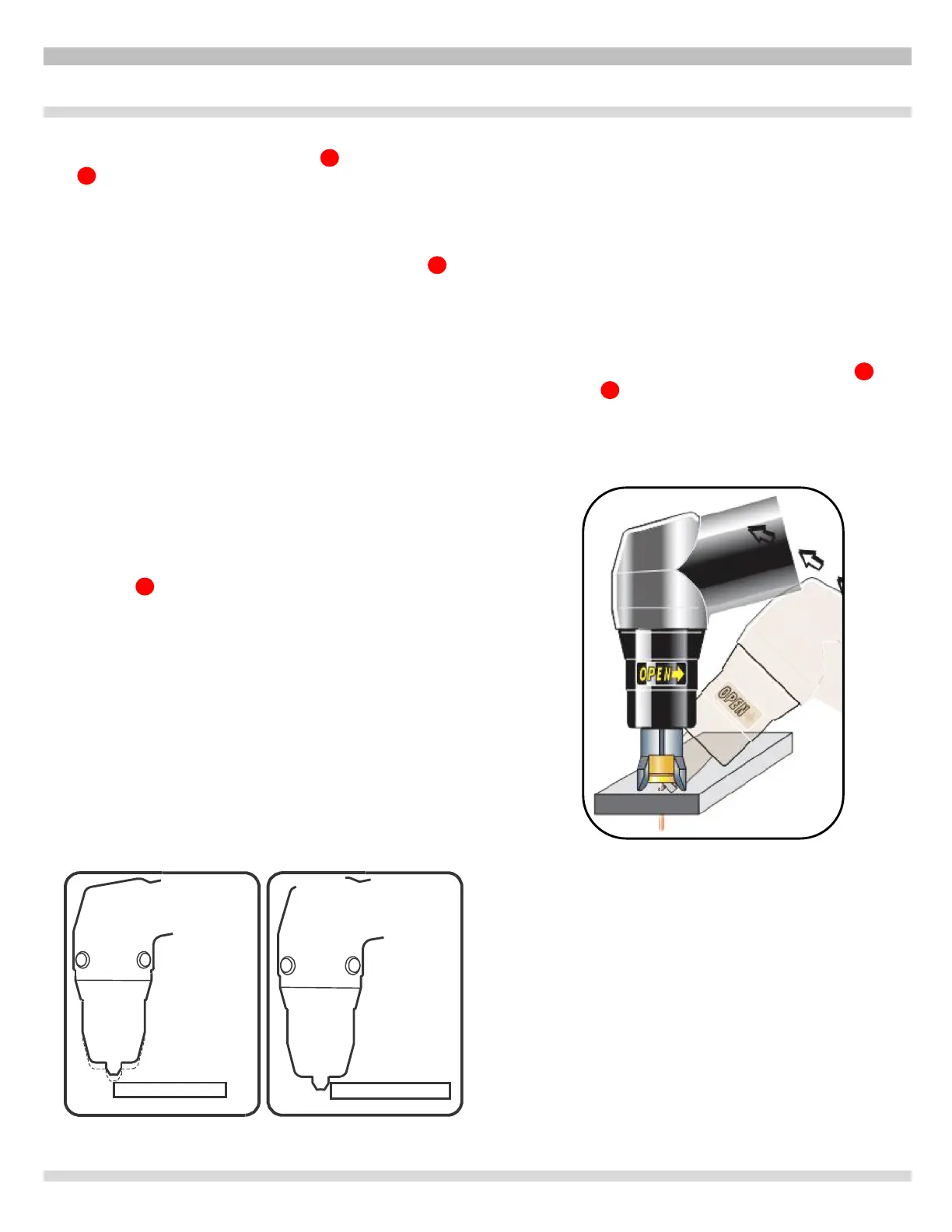

8. Begin cutting as shown in Fig. 2/A, avoid starting as

shown in Fig. 2/B

9. Hold the torch upright while cutting.

10. When you have finished cutting and released the

trigger, air will continue to leave the torch for

approximately 40 seconds to allow the torch to cool

down. It is best not to turn the machine off until

this cool- down period is complete.

• To cut perforated or grid metal, activate the "Pilot

self restart" function using the push-button P

(LED O lit). When you have finished cutting,

holding this push-button down will cause the pilot

arc to restart automatically. Use this function

only if necessary to avoid unnecessary wear

on the electrode and nozzle.

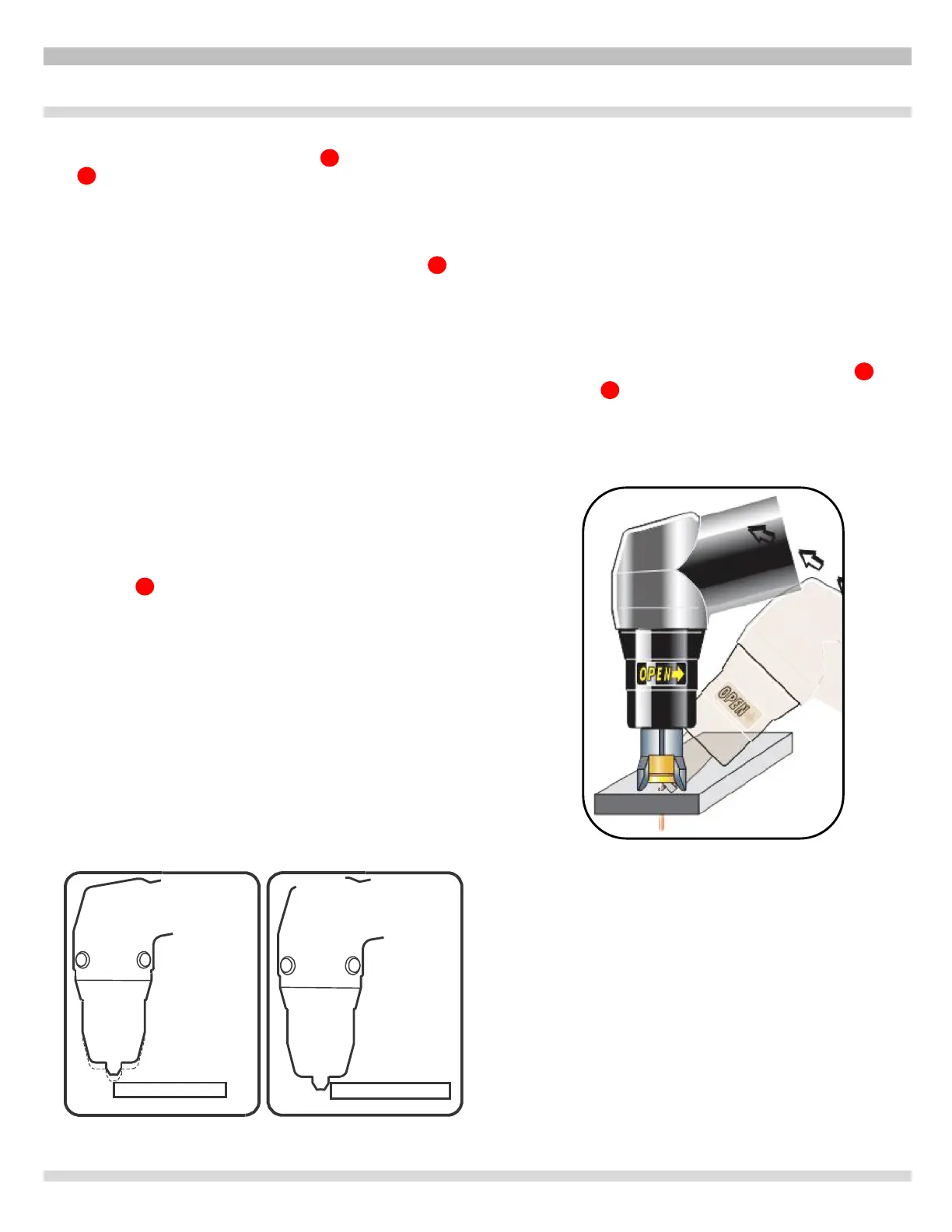

Should you need to make holes or begin cutting from

the center of the work piece, you must hold the torch

at an angle and slowly straighten it so that the nozzle

does not spray molten metal (see fig. 3). This must be

done when making holes in pieces more than 3 mm

or .118” thick. (12 gauge = .105”)

Should you need to cut several layers of metal, adjust

the cutting current to the minimum values.

Turn the machine off when the task is complete

Loading...

Loading...