INSUFFICIENT PENETRATION

This error may be caused by the following:

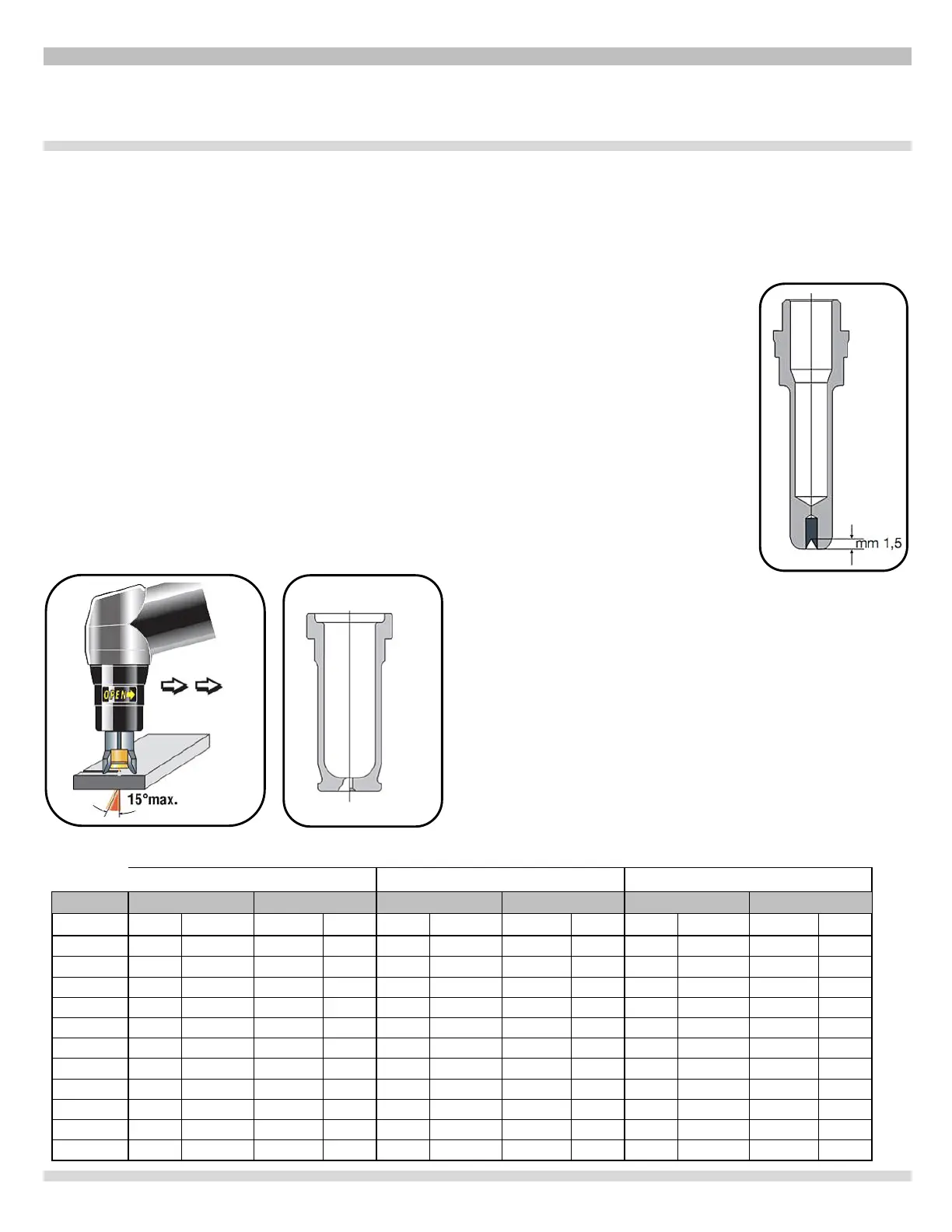

• High speed. Always make sure that the arc fully

penetrates the work piece and is never held at a forward

angle of more than 10 -15° (see Fig. 4). This will avoid

incorrect consumption of the nozzle and burns to the

nozzle holder (see Fig. 5).

• Excessively thick work piece (see “Cutting Thickness–

Speed” chart).

• Grounding clamp not in good electrical contact with the

work piece.

• Worn nozzle and electrode.

• Cutting current too low.

NOTE: When the arc does not penetrate, check the nozzle

for cutting slag blockage.

CUTTING ARC GOES OFF

This error may be caused by:

• Worn nozzle, electrode or swirl ring.

• Air pressure too high.

• Supply voltage too low.

REPLACING CONSUMABLE PARTS

Always shut off the machine before replacing

consumer parts.

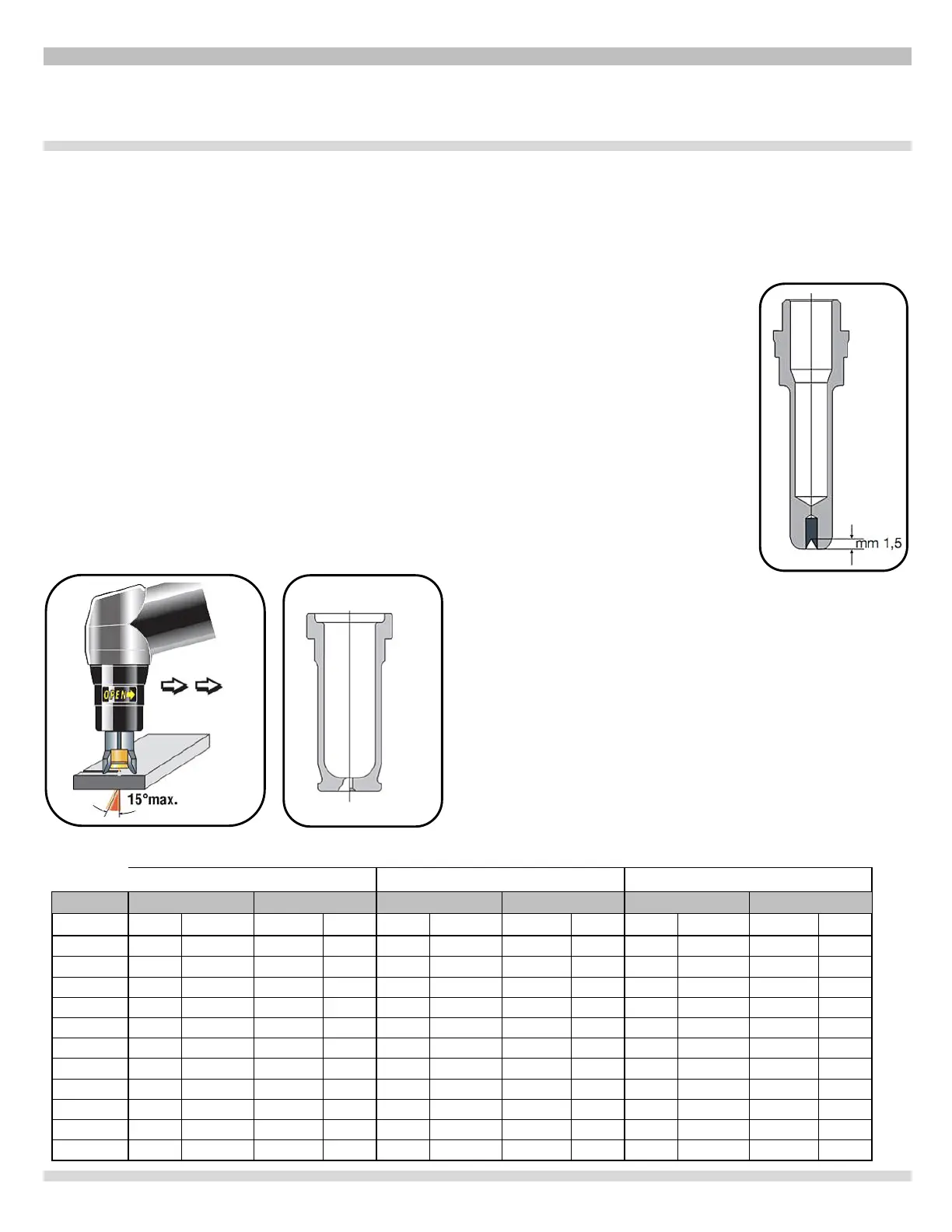

• The electrode must be replaced when it has a crater in the

center approximately 1 mm deep (.039”) or slightly over

1/32” (see Fig. 6).

• The gas nozzle must be replaced

when the hole is no longer smooth

and the cutting capacity is

diminished.

• The swirl ring must be replaced

when some areas are blackened.

Due to its small size, it is very

important to position it correctly

during assembly (see Fig. 4).

• The nozzle holder must be

replaced when the insulating part

is deteriorated

Make sure that the electrode T,

the swirl ring U and the gas

nozzle V are mounted correctly,

and that the nozzle holder W is

firmly tightened.

If any of these parts are missing, this will interfere with

smooth operation of the machine and, especially,

jeopardize operator safety

SHORTER LIFE OF CONSUMABLE PARTS

This error may be caused by:

• Oil or dirt in the arc intake,

• Unnecessarily long pilot arc,

• Low arc pressure.

Loading...

Loading...