By selecting TIG AC welding mode you may

weld

aluminum, aluminum alloys, brass and magnesium, while

selecting

TIG

DC allows you to weld steels,

stainless steel, iron and

copper

.

This welding machine is a direct and alternating

curr

ent

power source built using

INVERTER

technology, designed

to

weld covered electrodes

(not

including

cellulosic)

and for TIG

procedures, with contact starting and high

fr

equency

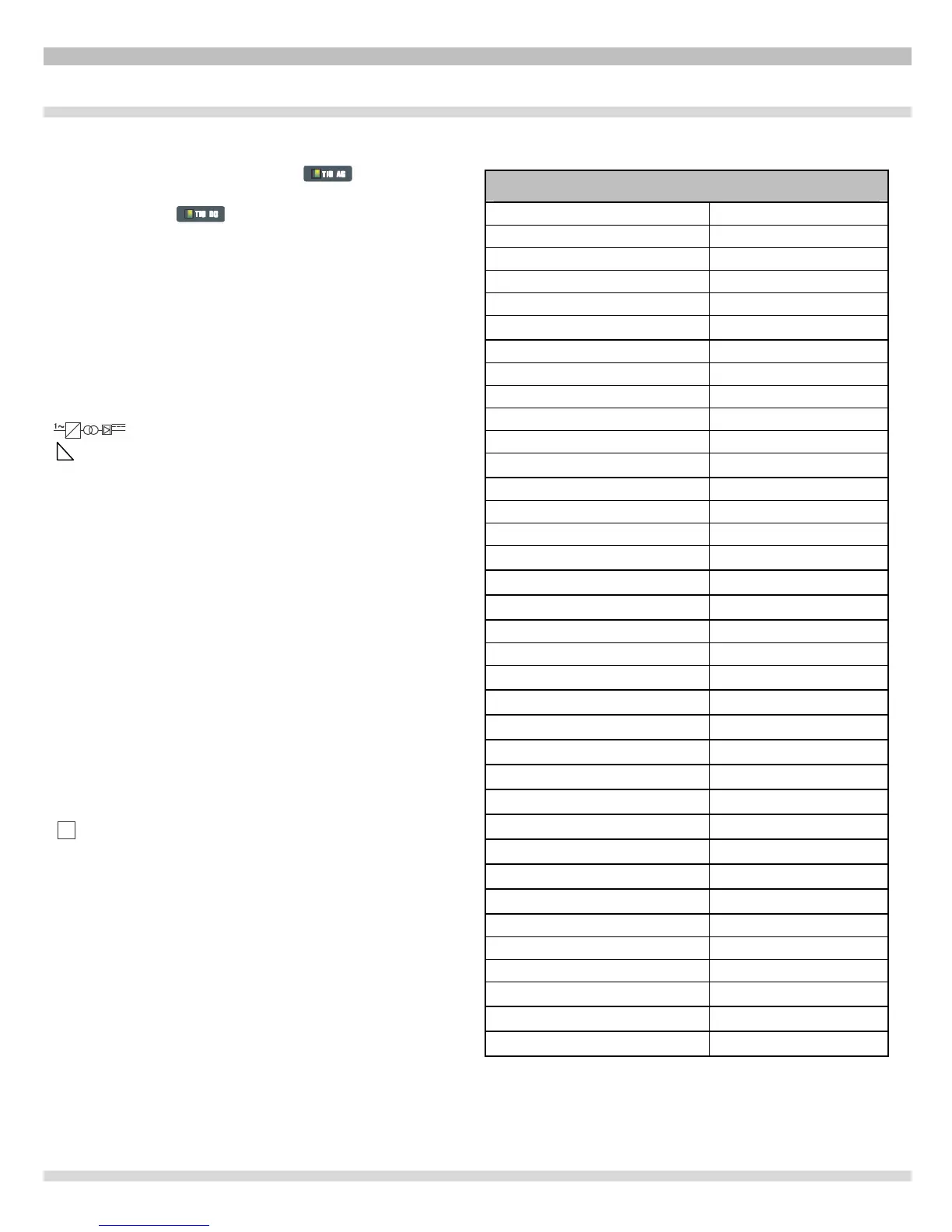

EXPLANATION OF THE TECHNICAL

SPECIFI

CATIONS

LISTED ON THE MACHINE PLATE.

N°. Serial number, which must be indicated on any type of

request regarding the welding machine.

Single Phase

Downslope.

TIG/MMA Suitable for TIG/MMA welding.

U0. Secondary open-circuit voltage (peak value)

X. Duty cycle percentage. % of 10 minutes

during

which the welding machine may run at a

certain

current without overheating.

I2. Welding

curr

ent

U2. Secondary voltage with current I2

U1. Rated supply

voltage

1~ 50/60Hz 50- or 60-Hz single-phase power

supply

I

1

Max Max. absorbed current at the

corr

esponding

current I

2

and voltage U

2

.

I

1

eff This is the maximum value of the actual

curr

ent absorbed, considering the duty

cycle.

This value usually corresponds to the

capa

city

of the fuse (delayed type) to be used as a

protection for the

equipment.

IP23S Protection rating for the housing. Grade 3 as

the second digit means that this machine may

be stored, but it is not suitable for use

out-

doors in the rain, unless it is

pr

otected.

S

Suitable for hazardous

envir

onments.

Loading...

Loading...