14 snapperpro.com

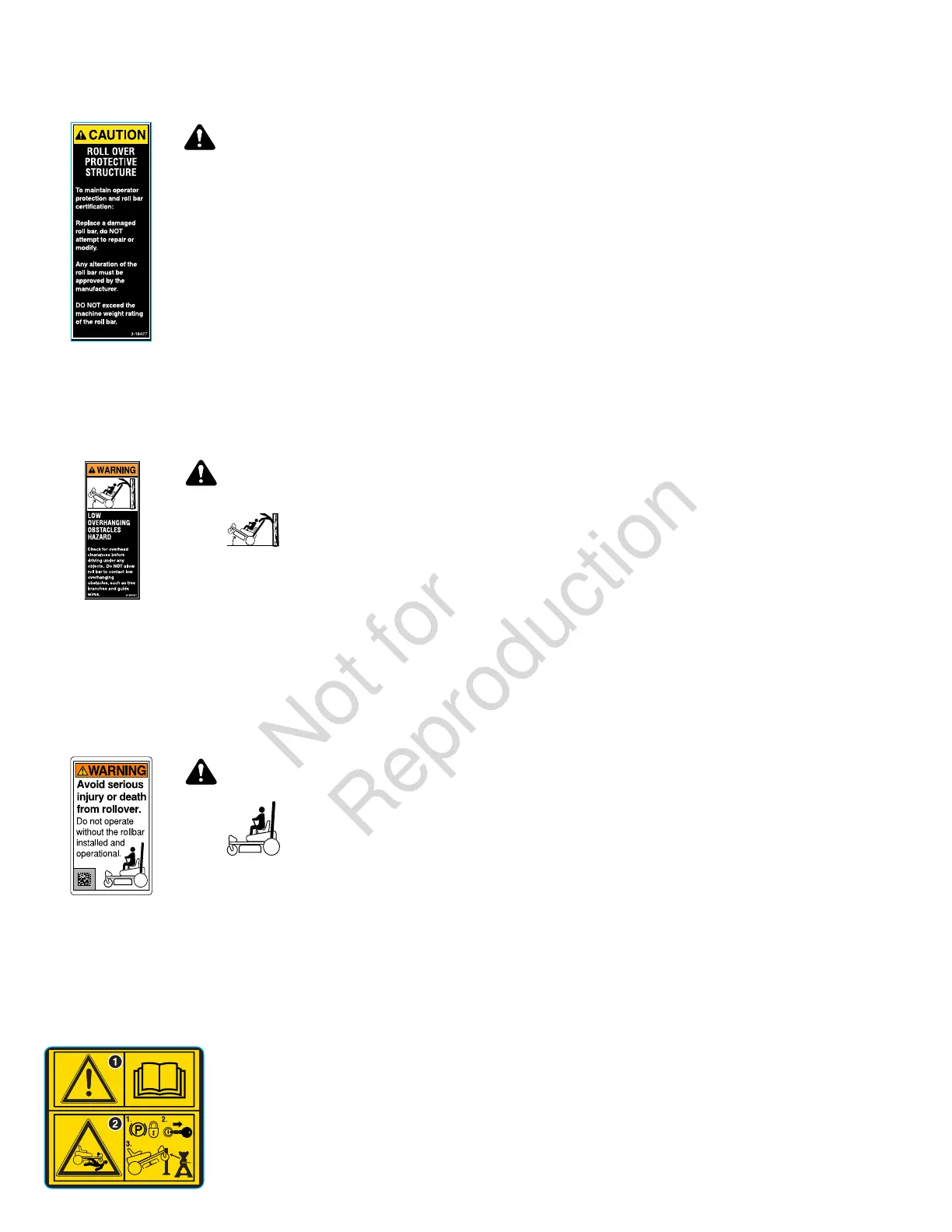

Decal, Caution, Folding Roll Bar

Part Number: 5104083YP

WARNING

Roll Over Protective Structure.

To maintain operator protection and roll

bar certification:

• Replace a damaged roll bar, do not

attempt to repair or modify.

• Any alteration of the roll bar must be

approved by the manufacturer.

• Do not exceed the machine weight

rating of the roll bar.

Decal, Warning, Roll Bar and Overhead

Obstacles

Part Number: 5100405YP

WARNING

Low overhanging

obstacles hazard.

• Check for overhead clearances

before driving under any objects.

Do not allow roll bar to contact low

overhanging obstacles, such as tree

branches and guide wires.

Decal, Warning, Roll Bar Removed

Part Number: 84008199

WARNING

Avoid serious

injury or death

from rollover.

• Do not operate without the roll bar

installed and operational.

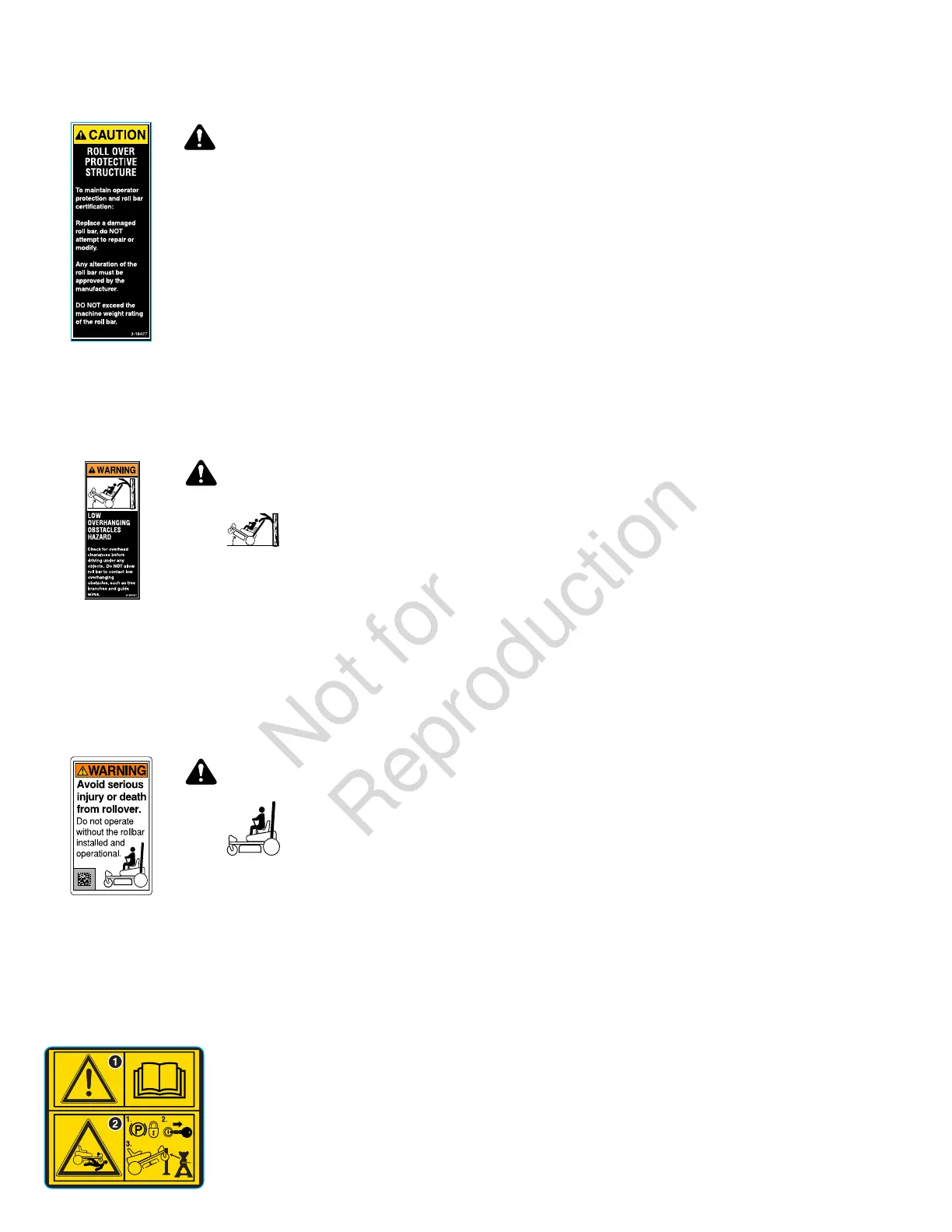

Safety Icons for Optional Jack Kit

Accessory

An optional jack kit is available as an accessory through your

normal parts source. Please see the explanations below for

the safety icons displayed on the jack kit.

Part Number:5105632 - Decal, Warnings, Svc Jack

1.) Warning - Read the Operator's Manual.

2.) Crushing Hazard, Mower:(1.) Park machine on flat

level ground and engage the parking brake; (2.) Stop the

engine and remove the ignition key; (3.) Properly jack the

machine and secure with jack stands before working under

the machine.

Safety Interlock System

This unit is equipped with safety interlock switches. These

safety systems are present for your safety, do not attempt

to bypass safety switches, and never tamper with safety

devices. Check their operation regularly.

Operational SAFETY Checks

Test 1 - Engine SHOULD NOT crank if:

• PTO switch is engaged, OR

• Parking brake is not engaged.

Test 2 - Engine SHOULD crank if:

• PTO switch is not engaged, AND

• Parking brake is engaged.

Test 3 - Engine should SHUT OFF if:

• Operator rises off seat with PTO engaged, OR

• Operator rises off seat with parking brake disengaged.

Test 4 - Blade Brake Check

The mower blades and mower drive belt should come to a

complete stop within seven (7) seconds after electric PTO

switch is turned off (or operator rises off seat).If the unit fails

the blade brake check, it is advised not to use the unit until it

is repaired and passes the blade brake check.

Note:Once the engine has stopped, PTO switch must be

turned off, parking brake must be engaged, and the ground

speed control levers must be locked in the NEUTRAL position

after the operator returns to the seat in order to start the

engine.

Features and Controls

Control Functions and Locations

The information below briefly describes the function of

individual controls. Starting, stopping, driving, and mowing

require the combined use of several controls applied in

specific sequences. To learn what combination and sequence

of controls to use for various tasks see the Operation section.

Loading...

Loading...