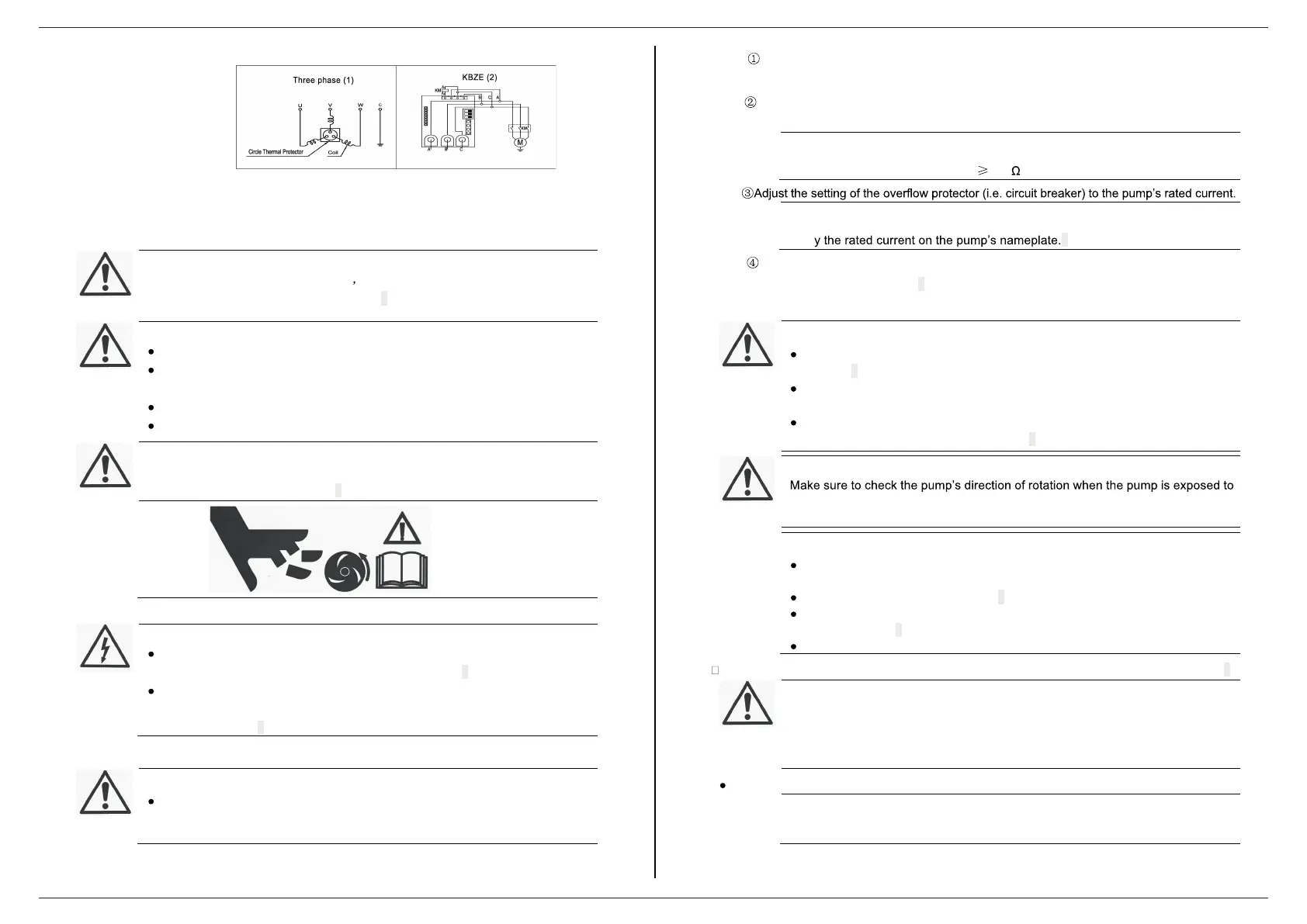

Electric circuit

diagrams

5. Operation

Precautions

If you need to work on the pump make sure that it is isolated from the

power supply and can not be energized.

Never operate the pump without safety devices installed.

Never operate the pump with the discharge hose blocked, or the discharge

valve closed.

Make sure you have a clear path of retreat.

Never work alone.

If the pump is equipped with automatic level control and/or internal contactor,

there is a risk of sudden restart.

Distance to wet areas

Risk of electrical shock. Make sure no one gets closer than 20 m to the unit

when being in contact with the pumped or mixed liquid.

Risk of electrical shock, This unit has not been investigated for use i n

swimming pools. If used in connection with swimming pools special safety

(1) Before operation

CAUTION:

Improper voltage and frequency of the power supply will prevent the pump from

attaining its full potential, and may also lead to current leakage, electrical

Once again, check the nameplate of the pump to verify that its voltage and

frequency are correct.

Check the wiring, power supply voltage, the capacity of the ground leakage circuit

breaker, and the insulation resistance of the motor.

NOTICE:

Insulation resistance reference value 30M . Please refer page 10 for the test method

NOTICE:

Verif

When using a generator, as much as possible avoid operating the pump in conjunction

with other types of equipment.

(2) Trial operation

WARNING:

Make sure that the unit can not roll or fall over and injure people or damage

property.

In some installations, the pump and the surrounding liquid may be hot. Bear in

mind the risk of burn injuries.

Make sure nobody is close to the unit when it is started. The unit will jerk in the

opposite direction of the impeller rotation.

atmosphere. Operating the pump in reverse while it is submerged in water will

damage the pump, which may lead to current leakage, electrical shock, or fire.

NOTE:

Inspect the pump. Check that there is no physical damage to the pump or

cables.

Check the oil level in the oil housing.

Remove the fuses or open the circuit breaker, and check that the impeller can

be rotated freely.

Check that the monitoring equipment (if any) works.

Operate the pump for a short time (1 to 2 seconds), and then check the correct pump rotation.

WARNING:

Before changing the connections for reverse rotation, make sure that the power

supply (i.e. circuit breaker) is properly disconnected and that the impeller has

stopped completely. Failure to observe this may lead to serious accidents,

including electrical shock, short, or injury.

Use a phase rotation indicator to check the correct pump rotation.

NOTICE:

When using a phase rotation indicator, please read the operation manual with it.

15 16

Loading...

Loading...