2. Miniature Protector Non-standard parts

built-in type temperature thermal protector is assembled for KBS415

KBS422

This protector is embedded inside the motor coil. If the coil should overheat for

any reason, bending of the bimetal of the miniature protector triggers a

signal, which in turn causes an external circuit in the starting console or control

panel to shut off the motor current. When the temperature returns to normal,

the protector is automatically reset, but restarting is controlled from the starting

console or control panel.

A b-contact miniature protector is adopted, which is normally "closed" and goes

to "open" upon overheating.

To protect the motor from current surges, be sure to install a motor breaker,

thermal relay or similar device in the external starting console or control panel.

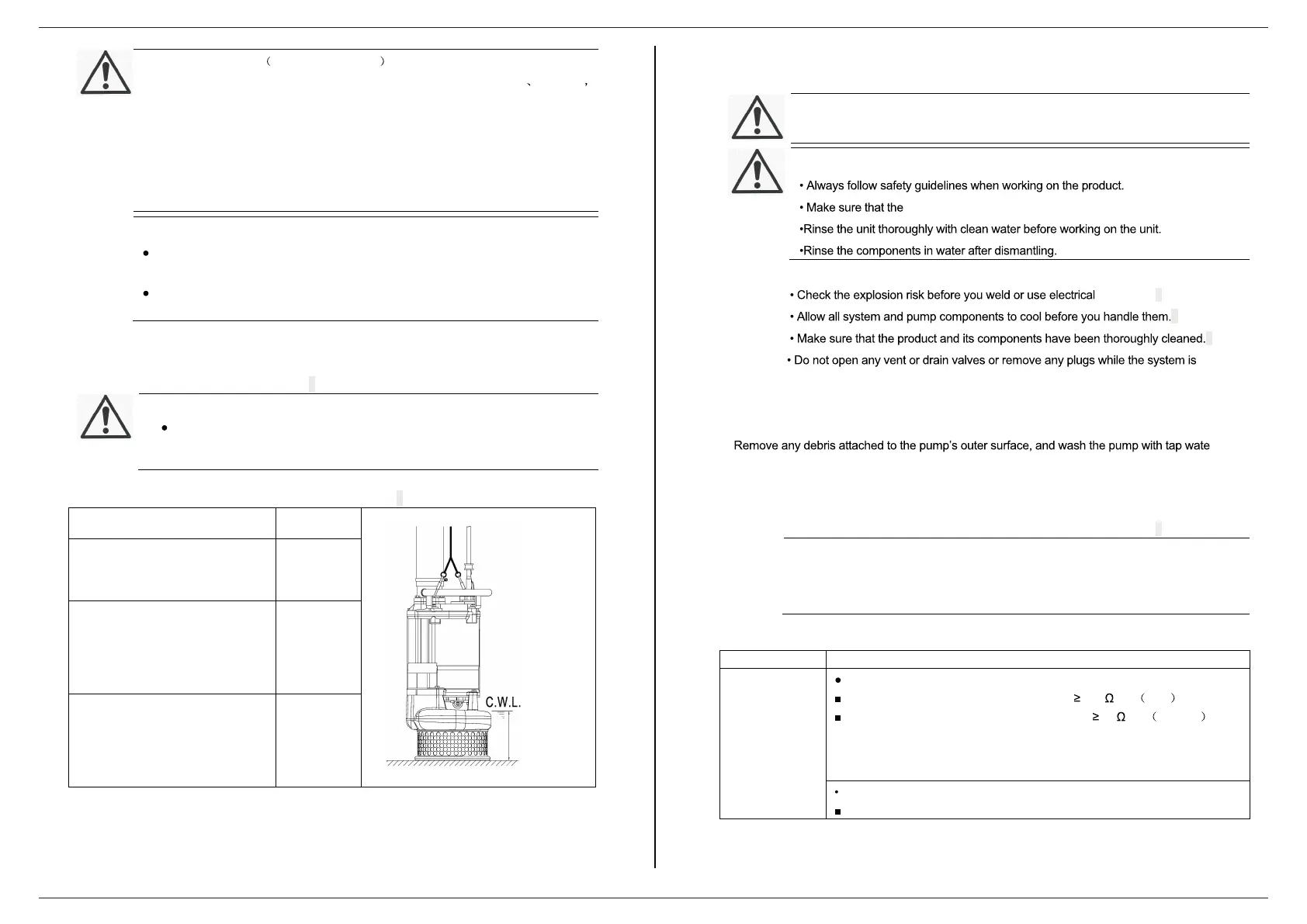

(5) Water level during operation

Pay attention to the water level during the pump operation. The pump will become

damaged if it is allowed to operate dry.

Do not operate the pump below Continuous running Water Level (C.W.L),

as doing so will damage the pump, causing current leakage and

The table below shows the water level during operation by output. Make sure

that the water level will not be under these levels.

MODEL C.W.L.

50TBZ(E)1.5 80TBZ(E)1.5

50TBZ(E)2.2 80TBZ(E)2.2

120 mm

50TBZ(E)3.7 80TBZ(E)3.7

100TBZ(E)3.7 80TBZ(E)5.5

100TBZ(E)5.5

150 mm

100TBZ7.5 150TBZ7.5

100TBZ11 150TBZ11

100TBZ15 150TBZ15

190 mm

The water level for the models which is not included in the tables: as per the picture

shown: the lowest water level should submerge the pump strainer

6. Maintenance and inspection

Precautions

DANGER:

Disconnect and lock out electrical power before installing or servicing the unit.

WARNING:

unit can not roll or fall over and injure people or damage property.

Make sure that you follow these requirements:

hand tools.

pressurized. Make sure that the pump is isolated from the system and that pressure is

relieved before you disassemble the pump, remove plugs, or disconnect piping.

Washing the pump

r. Pay

particular attention to the impeller area, and completely remove any debris from the impeller.

Inspecting the pump exterior

Verify that the paint is not peeled, that there is no damage, and that the bolts and nuts have not

loosened. If the paint has peeled, allow the pump to dry and apply touch-up paint.

Touch-up paint must be provided by the user. If the pump must be disassembled due

to damage or loose bolts or nuts, contact the dealer from whom you purchased

the equipment or the Solidpump sales office in your area.

(1) Inspection

Monthly

Measuring insulation resistance

cold Insulation resistance reference value 20M

min

cold .

thermal Insulation resistance reference value

1M min thermal

.

NOTE:

The motor must be inspected if the insulation resistance is considerably

lower than that obtained during the last inspection.

Measuring the loaded current

To be within the rated current

19 20

Loading...

Loading...