Monthly

Measuring the power supply voltage

Power supply voltage tolerance

a. continuous running: max±5% of the rated voltage.

b. intermittent running: max±10% of the rated voltage .

If the performance level has decreased considerably, the impeller may

Semi-annually

Inspection of lifting chain or rope

Inspecting and changing oil.

Yearly

Changing the oil and replacing the mechanical seal in the chamber.

Every 12 months or after 6,000 hours of use, whichever comes first.

NOTE:

Contact the dealer from whom you purchased the equipment or the

Solidpump sales office in your area to inspect and replace the

Once every

2 to 5 years

The pump must be overhauled even if the pump appears normal during

operation. The pump may need to be overhauled earlier if it is used

continuously or repeatedly.

NOTE:

Contact the dealer from whom you purchased the equipment or the

Solidpump sales office in your area to overhaul the pump.

(2)Storage

If the pump will not be operated for a long period of time, pull the pump up, allow it to dry, and store it indoors.

Be sure to perform a trial operation before reinstalling the pump. If the pump

remains immersed in water, operate the pump on a regular basis (i.e. once a

week) to prevent the impeller from seizing due to rust.

(3) Maintenance

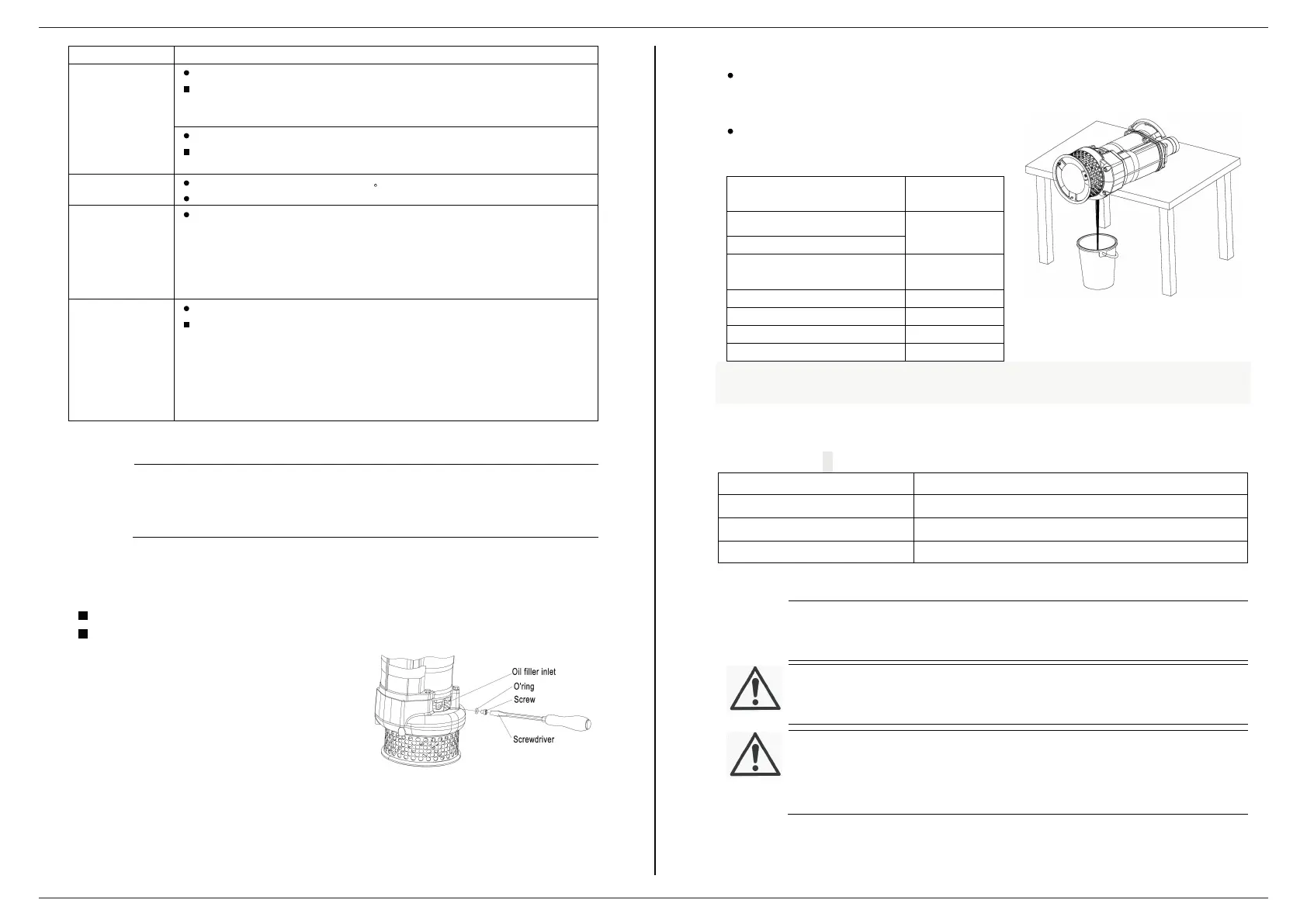

Inspecting oil and Changing oil

Inspecting oil

Designated oil: Turbine oil VG32.

Oil volume : Specified volume.

Remove the oil plug and take out a small amount

of oil. The oil can be extracted easily by tilting the

pump so that the oil plug faces downward. If the oil

appears discolored or intermixed with water, a

likely cause is a defective shaft sealing device

(i.e. mechanical seal), which requires that the

pump be disassembled and repaired.

Changing oil

Remove the oil plug and drain the oil completely.

Pour a specified volume of oil into the oil filler inlet.

NOTE:

The drained oil must be disposed of by waste

disposal contractors in compliance with the

laws of the located where the pump is being used.

The gasket and the O-ring for the oil filler plug

must be replaced with a new part at each oil

inspection and change.

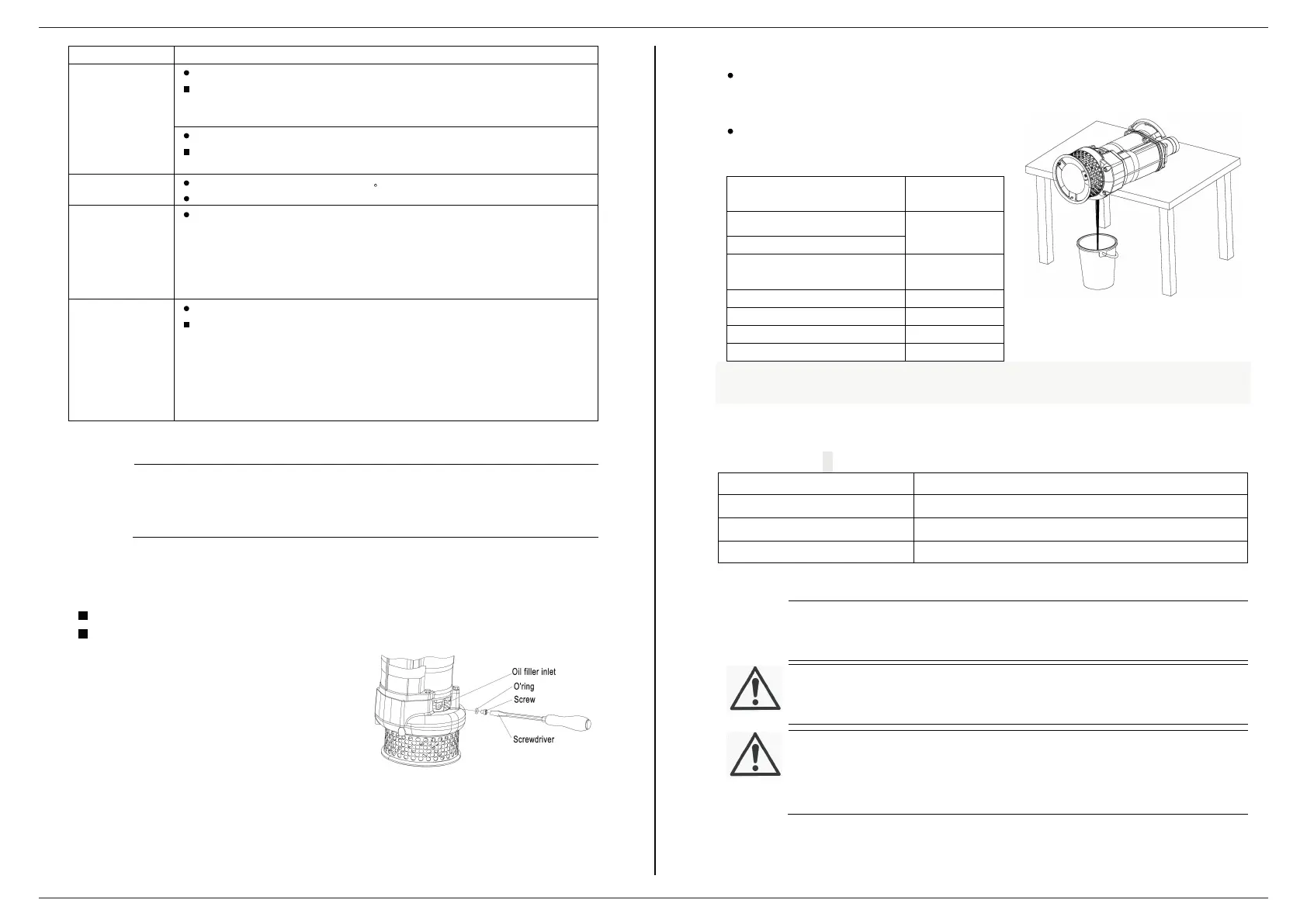

Model

50TBZ(E)1.5 80TBZ(E)1.5

620

50TBZ(E)3.7 80TBZ(E)3.7

100TBZ(E)3.7

1100

The oil volume for the models which is not included in the tables :about 80% of

the total oil cylinder capacity (theoretically, the oil level should cover the mating ring)

The parts listed below are dispensable items. As a rule of

thumb, Use the replacement period as a guide to replacing

these parts.

Gasket and O-ring Each disassembly or inspection

Oil seal Each disassembly or inspection or if the sealing lip is worn

(4)

Disassembly and reassembly procedure

Disconnect and lock out electrical power before installing or servicing

A worn impeller and/or pump housing can have very sharp edges.

Make sure to perform a trial operation when starting the pump after a

reassembly. If the pump was assembled improperly, it may lead to

abnormal operation, electrical shock, or water damage.

21 22

Loading...

Loading...