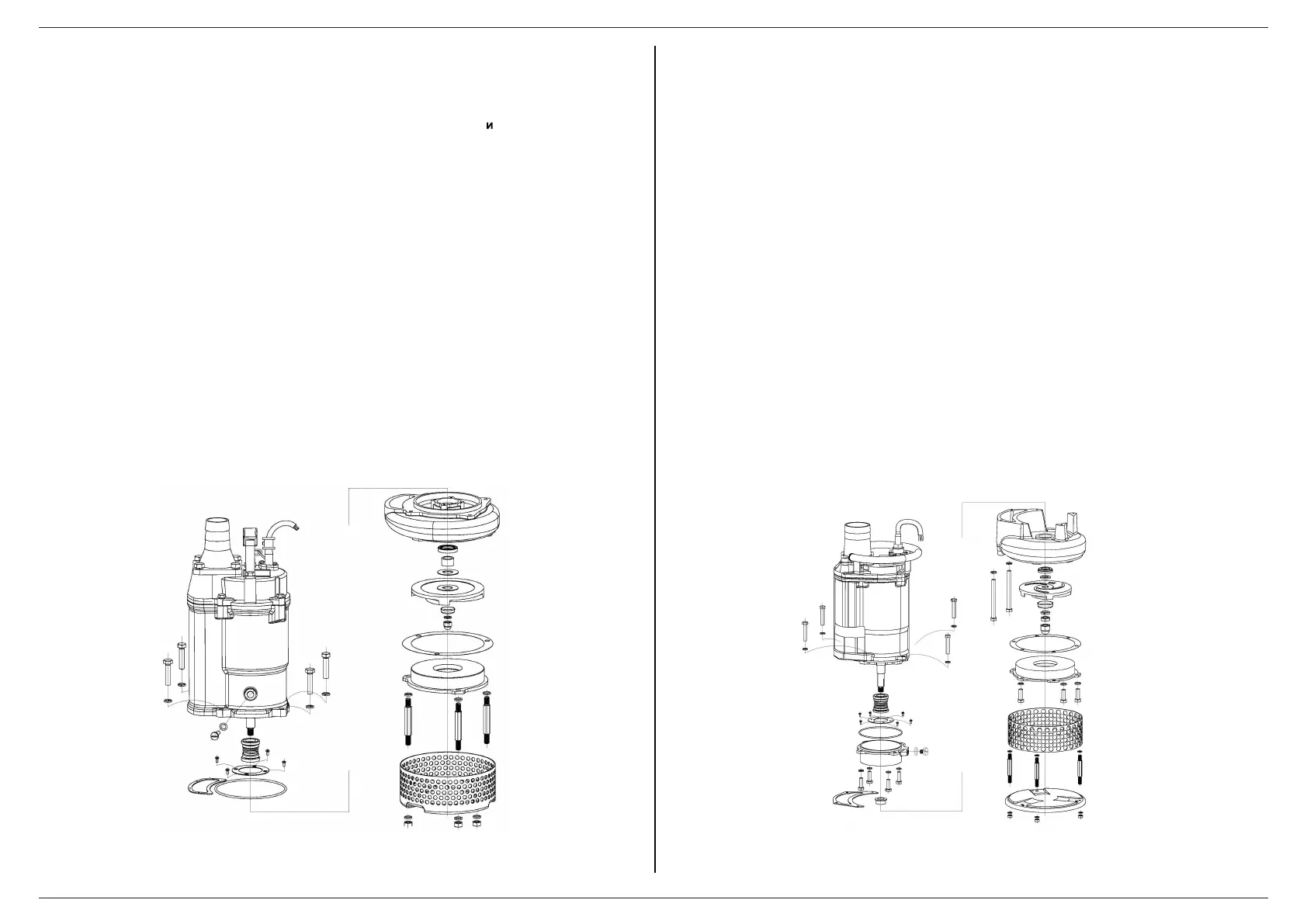

Disassembly Procedure for TBZ(E) 2.2~5.5kW

Note: before disassembling, be sure to drain the oil from the pump. Models

50TBZ(E)1.5, 80TBZ(E)1.5, 50TBZ2.2, 50TBZ(E)3.7, 80TBZ(E)3.7, 100TBZ(E)3.7,

80TBZ(E)5.5 and 100TBZ(E)5.5 have the same construction. However, models

50TBZ(E)3.7, 80TBZ(E)3.7, 100TBZ(E)3.7, 80TBZ(E)5.5, and

100TBZ(E)5.5 are

constructed without a shaft sleeve.

(1) Removing the strainer stand

Remove the hexagonal nut and the plain washer from the bottom and remove the

strainer stand from the pump.

(2) Removing the suction cover

Remove the hexagonal bolt (except 1.5/2.2 kW), plain washer, and the stud bolt,

plain washer, and remove the suction cover, suction cover packing from the

pump.

(3) Removing the impeller

Using a box wrench, remove the impeller nut, spring washer, and impeller thread

protective cover; then remove the impeller, impeller adjusting washer, shaft

sleeve (except 3.7/5.5 kW) from the

main shaft.

(4) If necessary, remove the pump casing, oil seal, O-ring and remove the

mechanical seal. After removing the hexagonal bolt and the spring washer,

remove the pump casing from the pump. At this time, be careful not to damage

the sliding surface of the mechanical seal. Remove the mechanical seal from

the main shaft.

NOTE:

The Exchange or maintenance of mechanical seal must be handled by the

qualified staff. If

you find any omissions, contact Solidpump sales office in your area.

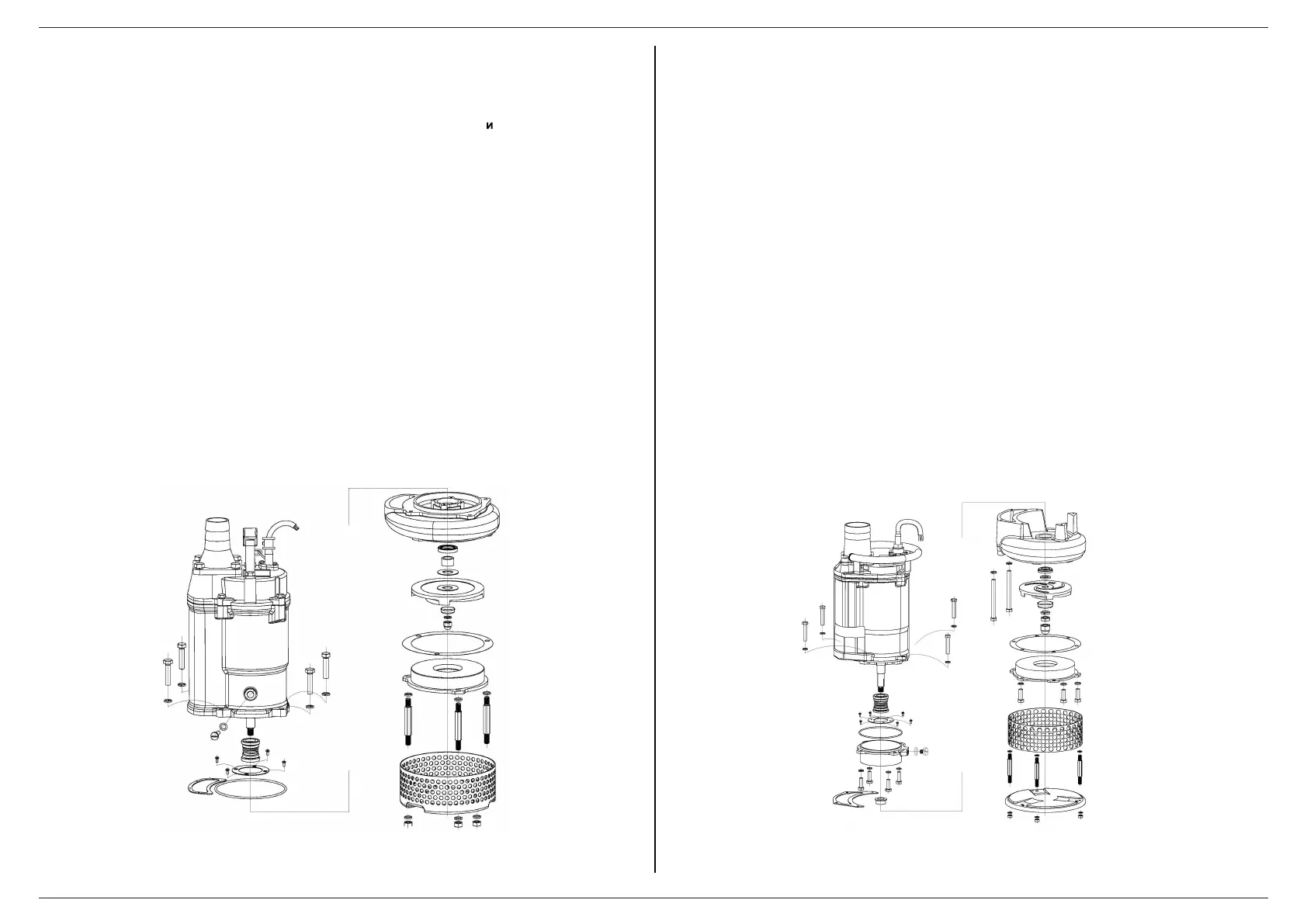

Disassembly procedure for TBZ 7.5~15kW

Note: before disassembling, be sure to drain the oil from the pump. Models

150TBZ7.5, 100TBZ11, 150TBZ11, 100TBZ15 and 150TBZ15

!have the

same construction.

(1) Removing the bottom plate and the strainer

After removing the hexagonal nut and the plain washer from the bottom,

remove the bottom plate and the strainer from the pump.

(2) Removing the suction cover

After removing the hexagonal bolt, plain washer, stud bolt, and the plain

washer, remove the suction cover and the suction cover packing from the

pump.

(3) Removing the impeller

Using a box wrench, remove the impeller nut, hexagonal nut, and the impeller

thread protective cover; then remove the impeller and the impeller adjusting

washer from the main shaft.

(4) Removing t

he pump casing

After removing the hexagonal bolt and the spring washer, remove the pump

casing, neck ring, O-ring, and the shaft sleeve from the pump.

(5) Remove the oil casing if necessary, and remove the mechanical seal.

After removing the hexagonal bolt and the spring washer, remove the oil

casing from the pump. At this time, be careful not to damage the sliding surface

of the mechanical seal. Remove the mechanical seal from the main shaft.

NOTE:

The Exchange or maintenance of mechanical seal must be handled by the

qualified staff. If

you find any omissions, contact Solidpump sales office in your area.

23 24

Loading...

Loading...