(4)

Grounding

You must ground all electrical equipment. This applies to the pump equipment,

the driver, and any monitoring equipment. Test the ground lead to verify that it

is connected correctly.

If the motor cable is jerked loose by mistake, the ground conductor should be

the last conductor to come loose from its terminal. Make sure that the ground

conductor is longer than the phase conductors. This applies to both ends of

the motor cable.

Risk of electrical shock or burn. You must connect an additional ground fault

protection device to the grounded connectors if persons are likely to come into

physical contact with the pump or pumped liquids.

To prevent damaging the pump and causing current leakage, which may lead to

electrical shock, be sure to install the ground wire securely.

To prevent electrical shock caused by improper grounding, do not connect the

ground wire to a gas pipe, water pipe, lightning rod, or telephone ground wire.

(5) Connecting the cables

These are the requirements to follow when you install cables:

The cables must be in good condition, not have any sharp bends, and not be pinched.

The sheathing must not be damaged and must not have indentations or be embossed

(with markings, etc.) at the cable entry.

The cable entry seal sleeve and washers must conform to the outside diameter of the cable.

The minimum bending radius must not be below the accepted value.

If using a cable which has been used before, a short piece must be peeled off when refitting

it so that the cable entry seal sleeve does not close around the cable at the same point

again. If the outer sheath of the cable is damaged, then replace the cable. Contact a

Solidpump service shop.

The voltage drop in long cables must be taken into account. The drive unit's rated voltage

is the voltage measured at the cable connection point in the pump.

Before connecting the cable to the terminal board, make sure that the power

supply (i.e. circuit breaker) is properly disconnected. Failure to do so may lead

to electrical shock, short, or injury caused by the unintended starting of the pump.

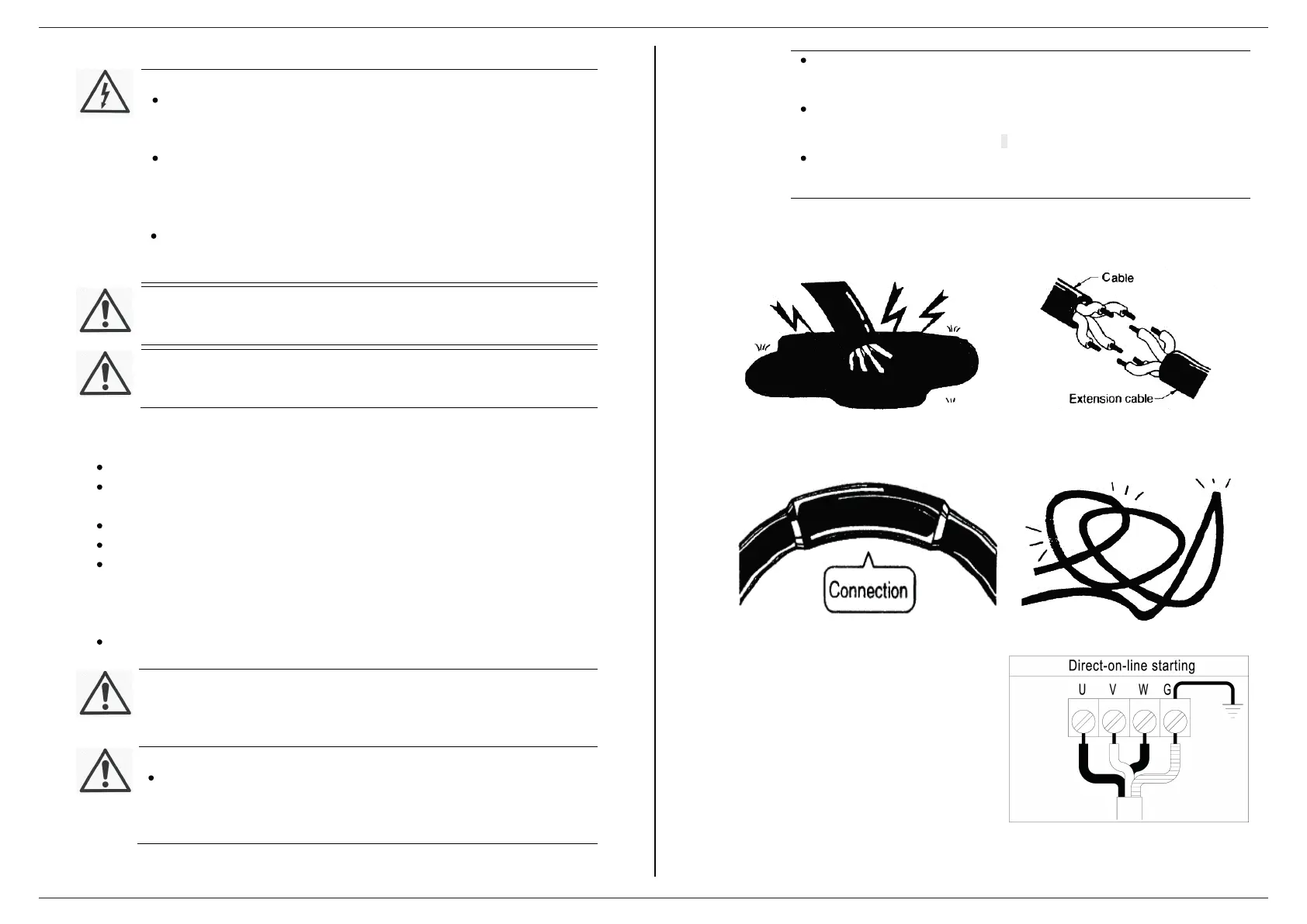

If the cable must be extended, use an extension cable with the same or larger

core size as that of the cable that is provided with the pump. Using a cable of

proper size will prevent the motor from attaining its full potential or may cause

the cable to overheat, which may lead to fire, current leakage, or electrical shock.

If a cable with a cut or damaged sheath is submerged in water, the water may

enter the pump and cause the motor to short. This will damage the pump,

which may lead to current leakage, or electrical shock, or burn-out.

To prevent the cable from cuts or twists, which will damage the pump and may

lead to current leakage, electrical shock, or fire, be sure that the tires of

vehicles do not run over the cable.

If the cable must be submerged in water, be sure to mold the connection

portion completely. Failure to do so may lead to current leakage, electrical

Never submerge the ends of a cable in water.

If the cable must be extended, use an

extension cable with the same or larger

core size as that of the cable that is

provided with the pump.

To prevent water from entering inside the cable,

be sure to securely mold the cable connection

portion.

To avoid damaging the cable, arrange the

cable run so that the cable is not bent,

kinked, or pressed against a structure.

a. Tighten the ends of the cable securely

against the terminal board.

b. The figure on the right shows how to

connect the cable properly

13 14

Loading...

Loading...