4. Installation

Disconnect and lock out electrical power before installing or servicing the unit.

Do not install the starter equipment in an explosive zone unless it is

explosion-proof rated.

Make sure that the unit can not roll or fall over and injure people or damage property.

WARNING:

Electrical shock hazard. Check that the cable and cable entry have not been

damaged during transport before installing the pump.

NOTICE:

Never force piping to make a connection with a pump.

These requirements apply:

Use the pump dimensional drawing in order to ensure proper installation.

Provide a suitable barrier around the work area, for example, a guard rail.

Check the explosion risk before you weld or use electric hand tools.

Remove all debris from the inlet piping system before you install the pump.

Always check the impeller rotation before lowering the pump into the pumped liquid.

CAUTION:

The supply voltage variation

a. continuous running: max±5% of the rated voltage.

b. intermittent running: max±10% of the rated voltage .

To use the pump, the water temperature should be between 0 and 40

.

The pump should be used only for pumping plain water. The pump should not

be used to pump fluids such as oil, salt water, or organic solvents.

The pump must never be used to pump explosive liquids and should not be

operated in an area from whom explosive elements might be present.

The pump must not be used in a partially disassembled state.

Do not use the pump in an area where the water pressure exceeds the

values given below, as it may damage the pump, or cause a short or

Maximum immersion depth

50TBZ(E)2.2 80TBZ(E)2.2

0.5Mpa(5kgf/cm

2

)-Discharge pressure during use

100TBZ(E)3.7 80TBZ(E)5.5

100TBZ(E)5.5

0.5Mpa(5kgf/cm

)-Discharge pressure during use

0.5Mpa(5kgf/cm

2

)-Discharge pressure during use

100TBZ11 150TBZ11

100TBZ15 150TBZ15

0.5Mpa(5kgf/cm

2

)

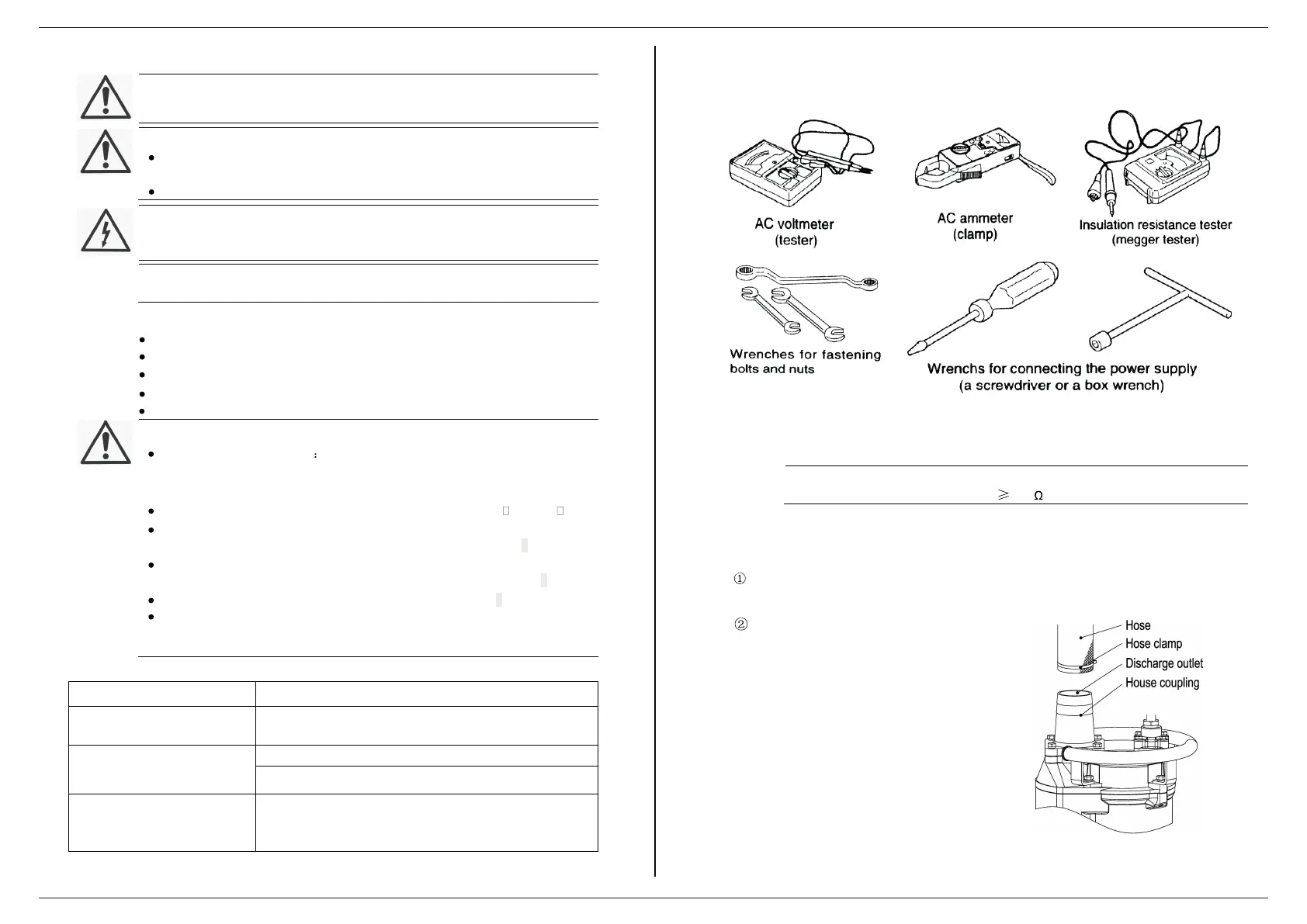

(1) Preparation for installation

Listed below are tools and instruments that are needed to install the submersible pump for

general dewatering purpose.

Pre-installation check

Measure the resistance between each of the core wires and the ground wire (yellow/green) to

verify the insulation resistance of the motor.

NOTICE:

Insulation resistance reference value 30M .

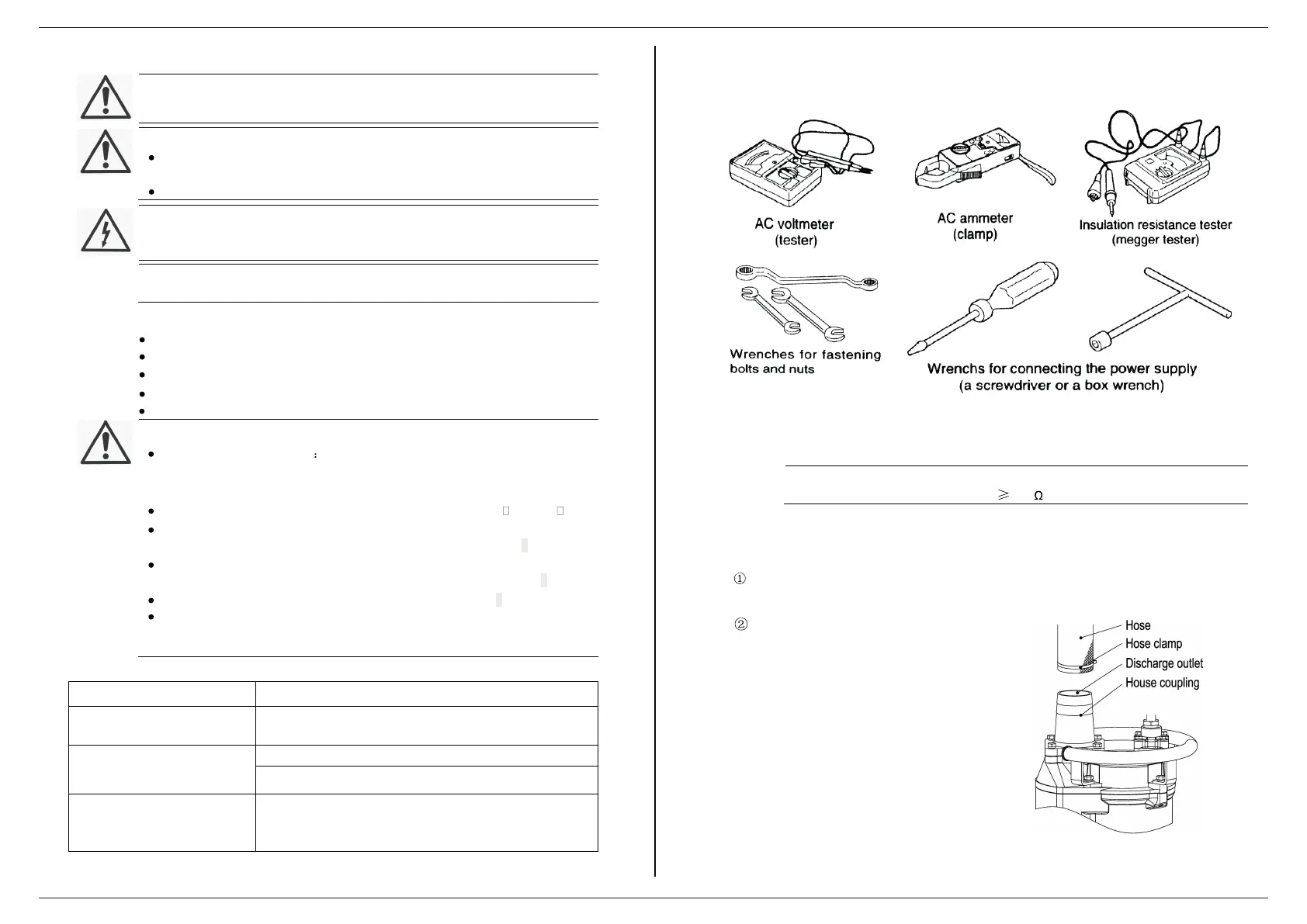

(2) Install the pump

The pump is transportable and intended to operate either completely or partially submerged in

the pumped liquid. The pump is equipped with a connection for hose or pipe.

Run the cable so that it has no sharp bends, is not pinched, and can not be sucked into the

pump inlet.

a. Soft pipe Installation:

Push the hose all the way to the base

of the hose coupling. Tighten the

hose clamp to secure the hose in

place.

9 10

Loading...

Loading...