Reassembly procedure

The reassembly procedure is the reverse sequence of disassembly.

NOTE:

After completing reassembly, do not forget to pour the specified amount of

oil into the pump.

The gaskets and O-rings must be replaced with new parts. Also replace

any parts that are worn or damaged.

Using a clean rag without oil, wipe the sliding surface of the mechanical seal. Apply oil to

the outer circumference of the cushion rubber to facilitate insertion.

NOTE:

For further details on how to install the mechanical seal, refer to the

that is sold separately as a spare part.

After installing the impeller, and after completing the reassembly, check that the impeller

rotates smoothly and that it does not come in contact with the diffuser.

To make sure that the pump operates normally, perform a trial operation before placing the

7. Trouble shooting

Personal injury hazard. Troubleshooting a live control panel exposes

personnel to hazardous voltages. Electrical troubleshooting must be

done by a qualified electrician. Failure to follow these instructions will

result in serious personal injury, death, and/or property damage.

Always disconnect and lock out power before servicing to prevent

unexpected startup. Failure to do so could result in death or serious

Read this operation manual carefully before requesting repair. After re-inspecting

the pump, if it does not operate normally, contact the dealer from whom you

purchased the equipment, or the

Solidpump sales office in your area.

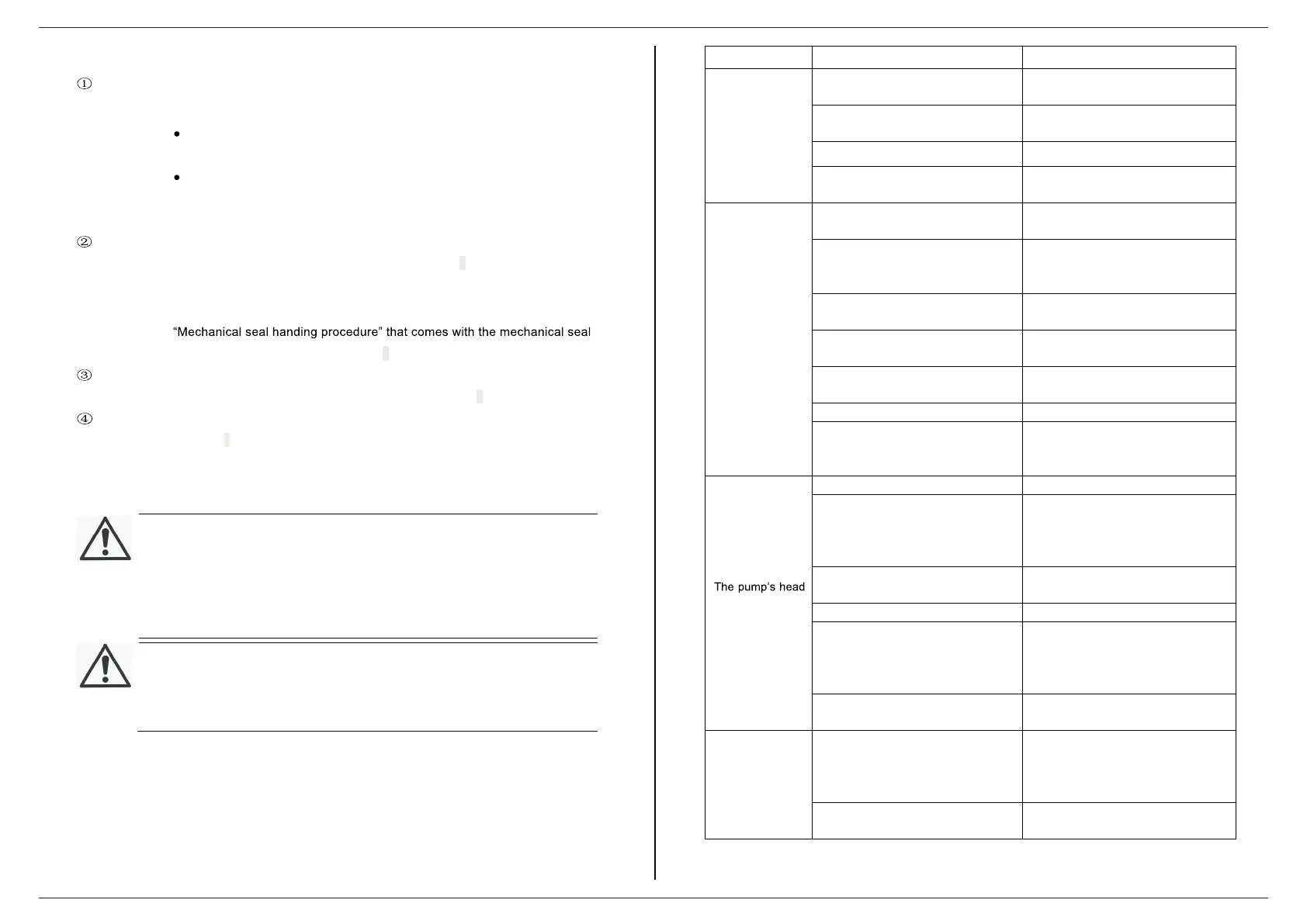

Symptom Cause Countermeasure

Pump fails to start

No power is supplied (i. e. power outage)

Contact the electric power company or

an electrical repair shop.

Open circuit or poor connection of

Check if there is an open circuit in the

Automatically control faults ( control panel)

Check the reason and then ask experts to repair

Impeller is obstructed

Inspect the pump and remove the

Pump starts but

stops immediately,

causing the motor

protector to actuate

Impeller is obstructed

Inspect the pump and remove the

Voltage drop

Correct the voltage to the rated

voltage, or use an extension cable that

Failure round thermal protector or

replacement or adjustment

A 50 Hz model is operated at 60 Hz.

Check the nameplate and replace the

The strainer is obstructed and the

pump was operated dry for long hours.

Remove the obstruction.

Repair the motor or replace with a new motor.

The pump is picking up too much

sediment.

Place a concrete block under the

pump to prevent the pump from

and pumping

volume is lower.

The impeller or suction cover is worn.

The hose may be kinked or clogged.

Minimize the number of bends in the

hose. (In an area with a large amount

of debris, use the pump in a meshed

The submerge depth of pump is too

shallow, there is air inhalation

Adjust the submerge depth until the

Check if the gate valve is open

The strainer is obstructed or buried.

Remove the obstruction. Place a

concrete block under the pump to

prevent the pump from picking up

The motor rotates in reverse.

Interchange the power supply terminal

The pump generates

noise or vibration

The bearing of the motor may be

damaged.

To replace the bearing, contact the

dealer from whom you purchased the

equipment or the Solidpump

sales

The shaft is bending

correct or contact with the nearest

25 26

Loading...

Loading...