Registered Quality System to ISO 9001:2008

22/60

Form 912

sorinc.com

913-888-2630

Tandem Float Units

Notes

1. Standard Units: It is important to consider the installation configuration when selecting the process

connection. Be sure that the float will fit through the process connection, or that the vessel has access to

attach the float from inside the vessel after instrument installation.

2. Tandem Float Units: It is important to consider the installation configuration when selecting the process

connection. Be sure that the float will fit through the process connection. Tandem floats are not removable

and must be installed through the nozzle opening. Operating specific gravity and insertion depths must be

specified.

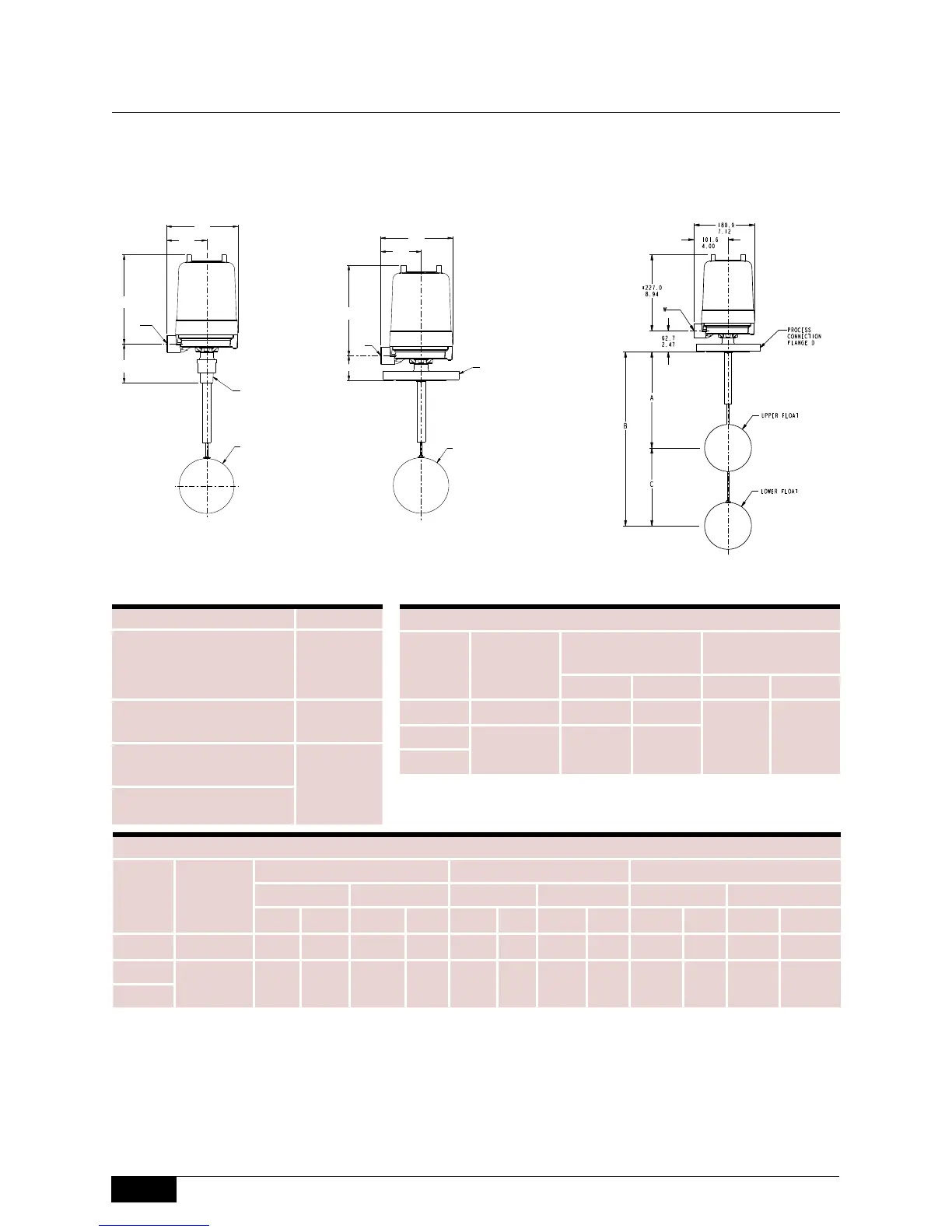

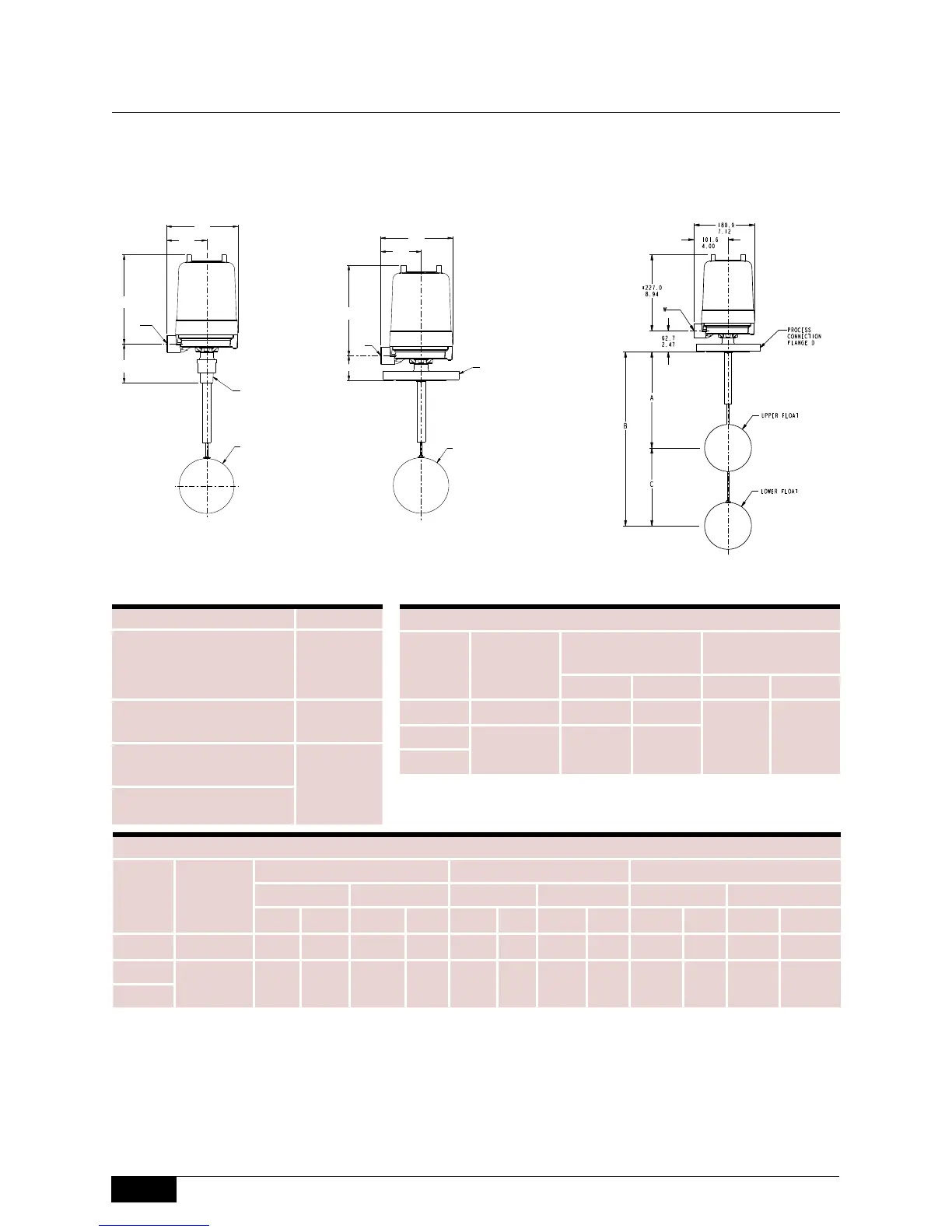

Unit Dimensions

Standard Units

Dimensions in this catalog are for reference only. They may be changed without notice. Contact the

factory for certified drawings for a particular model number. Dimensions are expressed as millimeters

over inches. (Linear = mm/in.)

** See Housing section (page 48).

***M20 adapters are brass.

Contact the factory for alternate materials.

300 Series

Standard Units

Series Float Size

Minimum

Insertion

Maximum

Insertion

mm inch mm inch

303 3-1/2 x 6” 114 4-1/2

1219 48

301

5-1/2” 108 4-1/4

304

Tandem Float Units

Series Float Size

High Insertion Low Insertion Differential

Minimum Maximum Minimum Maximum Minimum Maximum

mm inch mm inch mm inch mm inch mm inch mm inch

303 3-1/2 x 6” 114 4-1/2 1016 40 305 12 1219 48 203 8 1105 43-1/2

301

5-1/2” 108 4-1/4 1041 41 279 11 1219 48 178 7 1111 43-3/4

304

Housing** W

General Purpose

Explosion Proof

Explosion Proof

Explosion Proof

N4

N7

B1

B2

1” NPT

Pneumatic P1 (3) 1/4” NPT

ATEX

Flame Proof/IS

T6

S3 w/CL

M20 x 1.5***

TestSafe

Flame Proof

S3

S8

ISO-9001

14685 W 105TH ST LENEXA, KS 66215 USA

913-888-2630

SORINC.COM

101.6

4.00

180.9

7.12

99.2

3.91

FLOAT

227.0

8.94

Model Name: 0390053.ASSEM/3/3+

PRODUCT CERTIFICATION DRAWING

ALL DIMENSIONS ARE ±1/16 IN

UNLESS OTHERWISE SPECIFIED

MM

LINEAR =

IN

DRAWN BY

J REHM

CHECKED BY

M SMITH

ENGINEER APPROVAL

J FIFE

DATE

3/6/12

THIS DRAWING IS THE EXCLUSIVE PROPERTY OF SOR.

NO USE WHATSOEVER OF THE INFORMATION CONTAINED

HEREON, NOR REPRODUCTION IN WHOLE OR PART MAY BE

MADE WITHOUT THE EXPRESS WRITTEN PERMISSION OF SOR.

TITLE

DIM DWG 300 SERIES 1" NPT

(FLOAT OPERATED)

EO NUMBER: 5154

SCALE: 0.33

DO NOT SCALE PRINT

DRAWING NUMBER REV

0390053 4

SHEET 1 OF 1

DWG SIZE

B

NOTES:

1. FLOAT SIZE IS BASED ON MINIMUM DIFFERENTIAL SETTING,

MINIMUM LIQUID SPECIFIC GRAVITY, AND SINGLE SWITCH FUNCTION.

2. CAUTION MUST BE USED IN SELECTING MOUNTING NOZZLE PIPE

SCHEDULE TO PROVIDE FLOAT INSERTION CLEARANCE.

PROCESS

CONNECTION

1 NPT(M)

W

Drawing

0390053

ISO-9001

14685 W 105TH ST LENEXA, KS 66215 USA

913-888-2630

SORINC.COM

C

101.6

4.00

180.9

7.12

FLOAT

227.0

8.94

Model Name: 0390007.ASSEM/3/0+

PRODUCT CERTIFICATION DRAWING

ALL DIMENSIONS ARE ±1/16 IN

UNLESS OTHERWISE SPECIFIED

MM

LINEAR =

IN

DRAWN BY

J REHM

CHECKED BY

M SMITH

ENGINEER APPROVAL

J FIFE

DATE

3/6/12

THIS DRAWING IS THE EXCLUSIVE PROPERTY OF SOR.

NO USE WHATSOEVER OF THE INFORMATION CONTAINED

HEREON, NOR REPRODUCTION IN WHOLE OR PART MAY BE

MADE WITHOUT THE EXPRESS WRITTEN PERMISSION OF SOR.

TITLE

DIM DWG 300 SERIES FLANGED

FLOAT OPERATED

EO NUMBER: 5154

SCALE: 0.33

DO NOT SCALE PRINT

DRAWING NUMBER REV

0390007 4

SHEET 1 OF 1

DWG SIZE

B

NOTES:

1. FLOAT SIZE IS BASED ON MINIMUM DIFFERENTIAL SETTING,

MINIMUM LIQUID SPECIFIC GRAVITY, AND SINGLE SWITCH FUNCTION.

2. CAUTION MUST BE USED IN SELECTING MOUNTING NOZZLE PIPE

SCHEDULE TO PROVIDE FLOAT INSERTION CLEARANCE.

W

PROCESS

CONNECTION

FLANGE B

Drawing

0390007

Drawing

0390665

Minimum 5-3/4’’ (146 mm) overhead clearance required to remove housing cover.

Loading...

Loading...