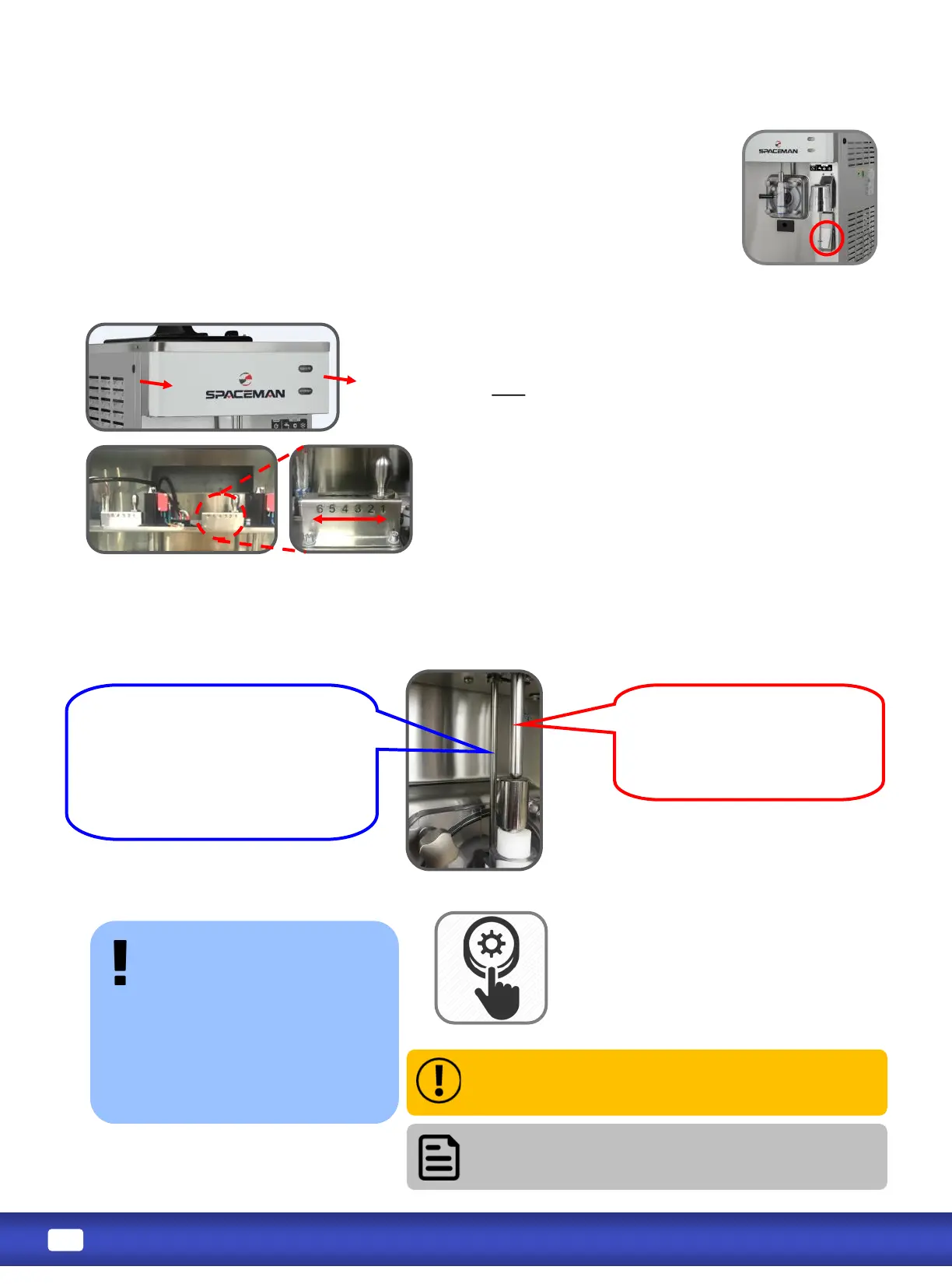

Located directly above the draw valve, this arm tells the machine when product is being dispensed

and how rm the product is. Beater and cooling systems are turned on and o based on

informaon from the sensor arms.

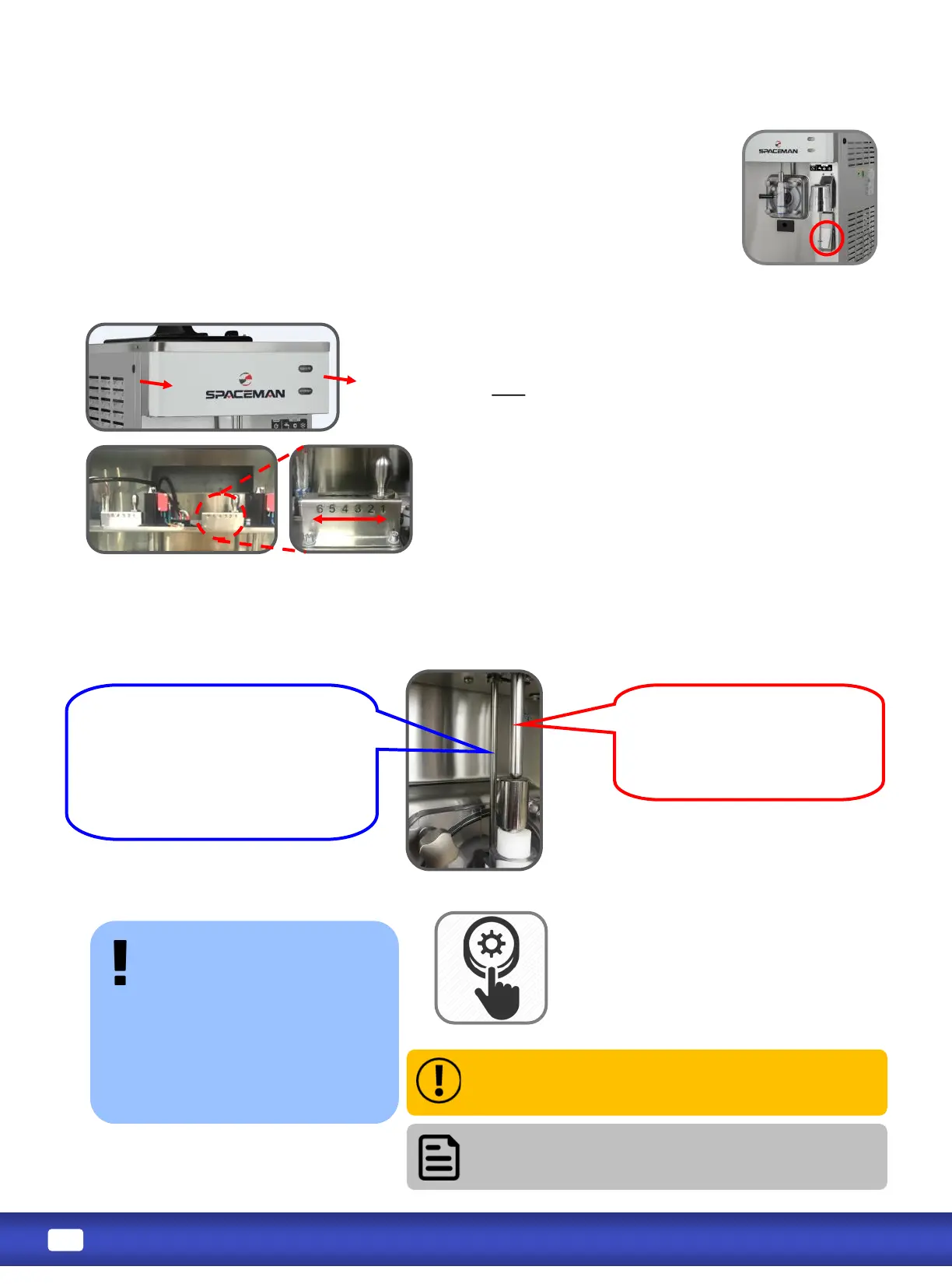

The viscosity adjustment, located behind the faceplate,

controls the rmness of dispensed product. The higher the

viscosity, the more rm the product. Viscosity sengs

should NOT need connuous adjustment.

Take o the faceplate. Viscosity is from Soer to Harder

from level 1 - 6. Make small adjustments each me, and

allow at least 10 to 15 minutes between adjustments to

evaluate product rmness.

Arm moves up and down and

tells machine when product is

being dispensed.

It moves UP when draw handle

is in the OPEN posion.

Flat arm moves le and right and

tells machine when product is at

desired consistency.

Switched RIGHT means consistency

is correct. Switched LEFT or IN THE

MIDDLE means consistency is not

yet correct.

If machine doesn’t turn on, turn power switch

OFF, wait 30 minutes, and repeat steps 1 to 4. If

problem persists, contact service team.

If machine makes any abnormal noise

during reset, immediately turn power switch OFF

and contact service team.

-(usually

because the viscosity is set too

high for the selected product to

prevent motor damage.

Use the green reset buon on

the machine’s back panel to

return the machine to normal

operaon.

1. Turn power switch to OFF.

2. Firmly press green reset buon.

3. Wait 15 to 20 minutes.

4. Turn power switch to WASH.

5. Observe machine performance.

Spinner operaon is controlled by the paddle switch on lower poron of the

spinner mount.

The paddle switch is designed for one-hand operaon. Hold cup up towards

the spindle while pressing in the paddle switch with the same hand. Spinner

will turn on and stay on. Spinner will stop as soon as paddle switch is released.

Loading...

Loading...