Promise to Perform Industries, Inc.

A-SERIES ALUMINUM GANTRY CRANE MANUAL

18 Spanco

®

A-Series Aluminum Gantry Crane

• 1-800-869-2080 • Spanco.com

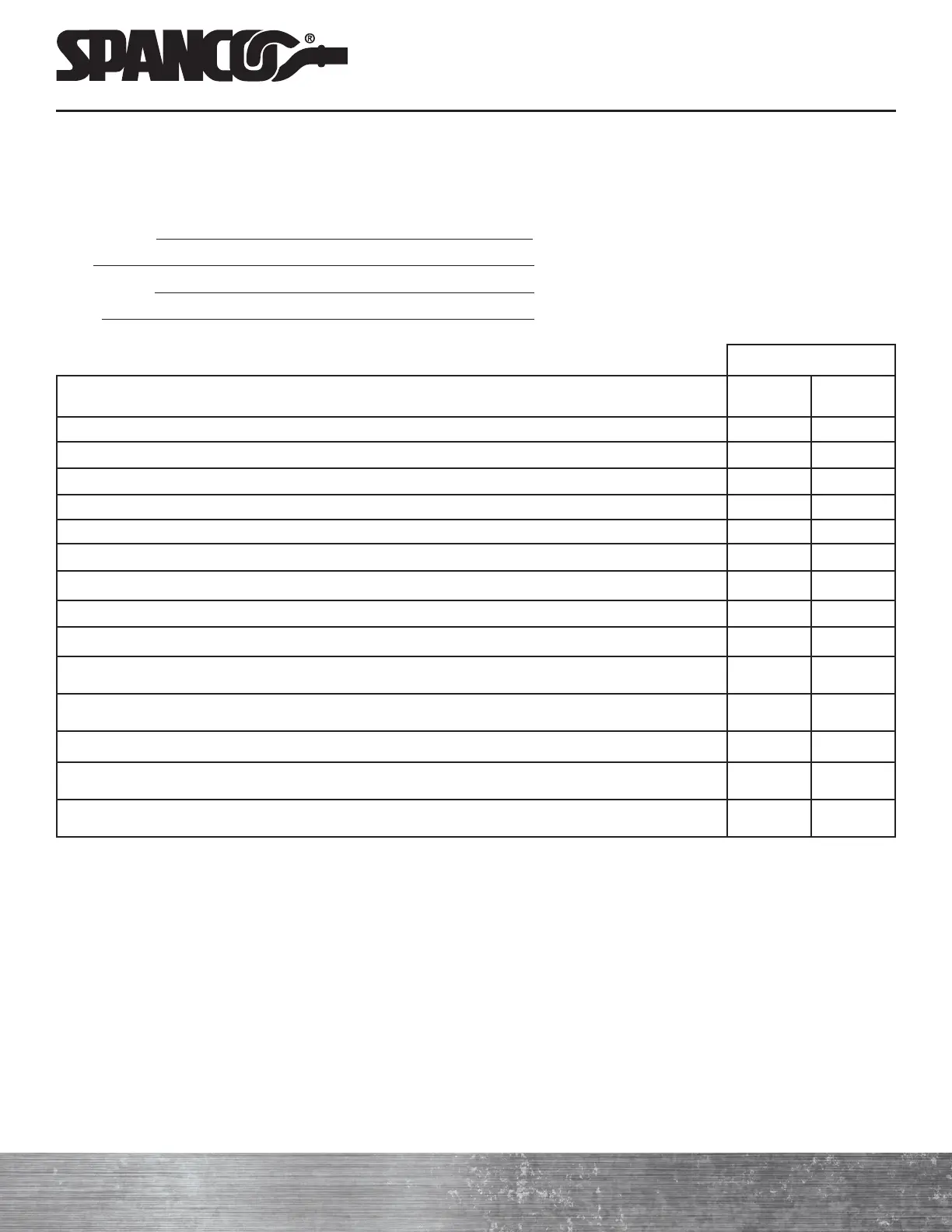

ANNUAL GANTRY CRANE SYSTEM

INSPECTION CHECKLIST

Inspector Name:

Date:

System Number:

Model:

Inspection Result (

3

)

INSPECTION POINTS PASS FAIL

1. Using a torque wrench, check that all bolts are present and torqued to values shown in the system manual.

2. Verify that capacity labels are present, attached, and legible.

3. Check the beam flanges. Track flanges cannot be bent downward.

4. Check the beam flange thickness. Beam flange thickness cannot be worn more than 10 percent.

5. Check all system welds for cracks.

6. Check system components for corrosion and bent or damaged areas.

7. Verify that the hoist can traverse the entire length of the beam without snags.

8. Inspect the hoist per the manufacturer’s instructions.

9. Check system components for loose components.

10. Check that all wheel studs, if supplied, are torqued to the value shown in the system manual. Note that these 1/2-inch

wheel studs have a different torque value than other 1/2-inch bolts.

11. Check motorization components, if supplied, for improper performance or noncompliance with applicable safety

requirements.

12. Check drive chain sprockets, if supplied, for excessive wear and excessive chain stretch.

13. Check the electrical apparatus, if supplied, for any deterioration of the controller contactors, limit switches, and push

button stations.

14. Check system for unauthorized modifications. Only Spanco can authorize modifications. Remove system from service if

it is modified in anyway.

©2022. All Rights Reserved. All specifications and product designs subject to change without prior notice.

Loading...

Loading...