12

3.1 Function

The product can be configured to control TDS / conductivity of water.

Once fully commissioned, the TDS value is displayed in μS/cm (or ppm if selected).

Note: Conductivity is expressed in parts per million (ppm) or micro Siemens per centimetre

(µS/cm). Micro Siemens /centimetre is becoming the more common unit, and is therefore

the default setting.

If the water conductivity exceeds the Set Point level, the TDS value shown on the display will

alternate with ‘bLd', and the valve relay will be energised until the conductivity drops below 5%

of full scale (FS) below the set point.

If the system is carrying out a purge, The TDS value will alternate with 'Pur', and the valve

relay will be energised until the conductivity drops 5% (FS) below the Set Point.

If the water conductivity exceeds the alarm level, the displayed TDS value will alternate

with 'AL', and the valve relay will be energised until the conductivity drops 3% (FS) below

the alarm level.

3.2 Inputs

The product can accept a signal from a Spirax Sarco conductivity probe (CP10 or CP30)

and a Pt100 temperature sensor. A CP32 probe may also be used with the BC3150, but will

not provide the scale monitoring and self-cleaning features.

A Pt100 temperature sensor may be connected to provide temperature compensation (2%/°C).

This is recommended if the boiler is working at varying pressures, or for other applications,

such as condensate monitoring or coil boilers, where the temperature may vary. If a Pt100 is

not fitted, the product uses a default temperature of 184°C (10 bar g).

3.3 Outputs

3.3.1 Continuous output

Used when the probe is mounted in the boiler. The probe is able to constantly monitor the

conductivity from the probe tip to the boiler shell.

3. System overview

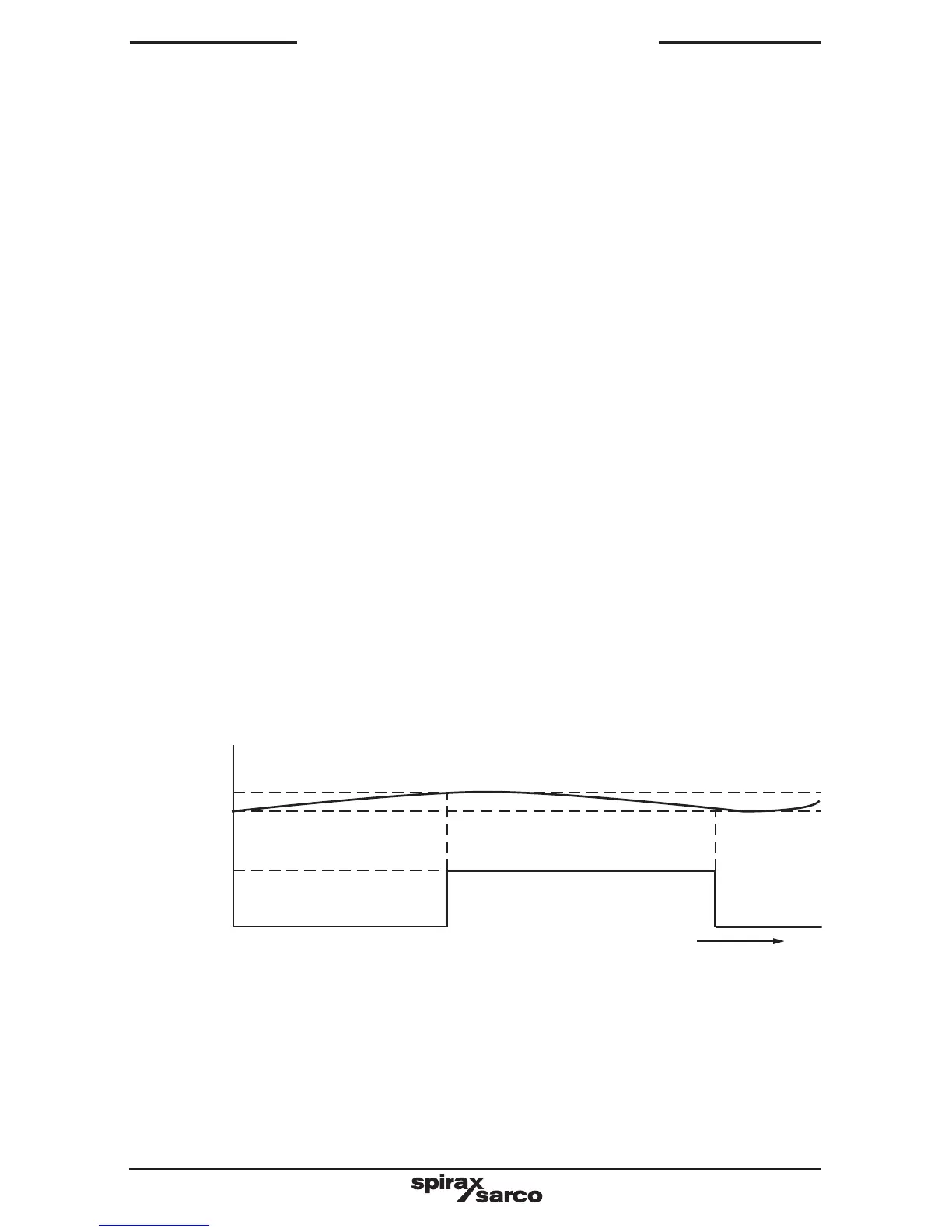

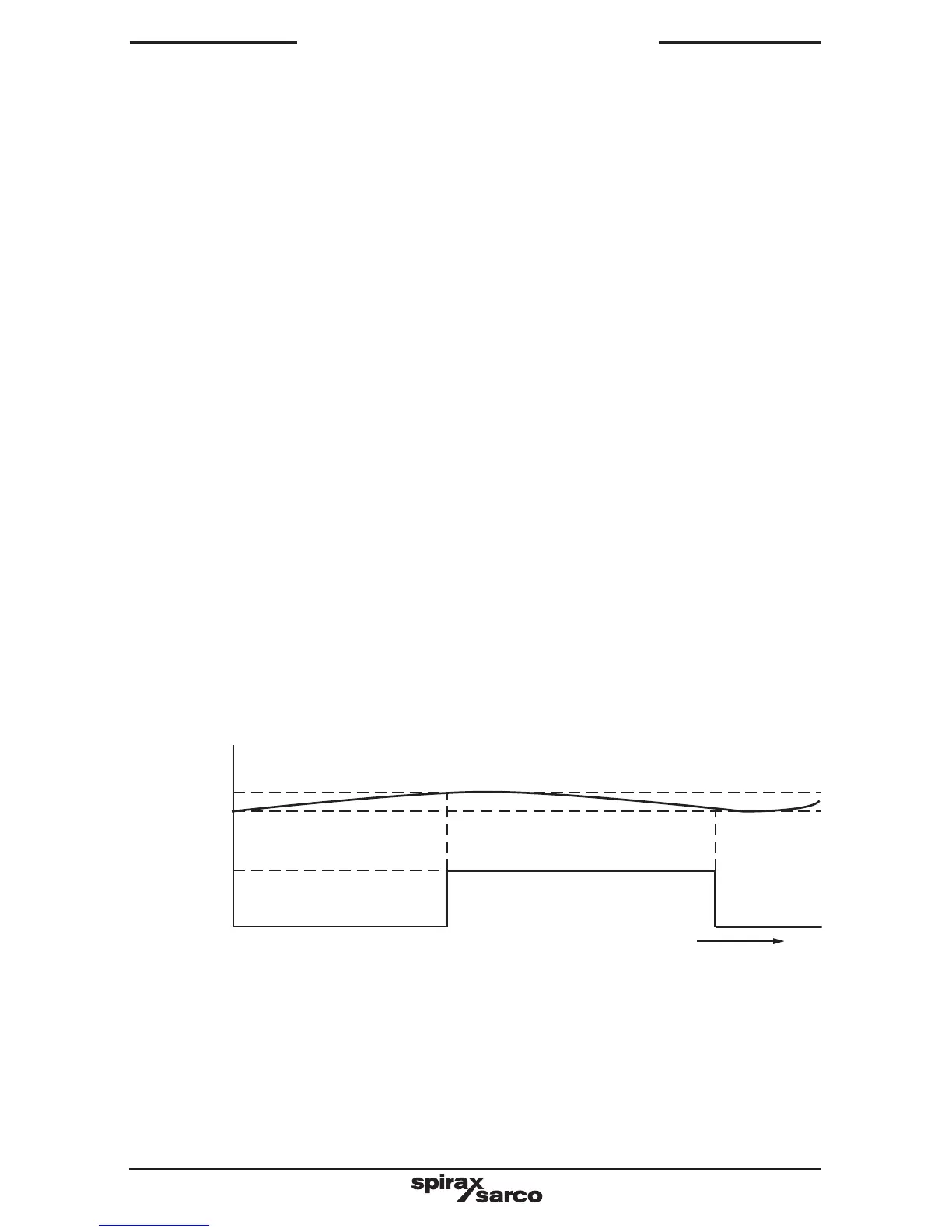

Fig. 2 Continuous output (purge time = 0s)

Water

conductivity

SP

Hysteresis

Valve

open

Closed

High conductivity

Time

Blowdown

Keeps valve open until

conductivity drops below

hysteresis

Loading...

Loading...