38

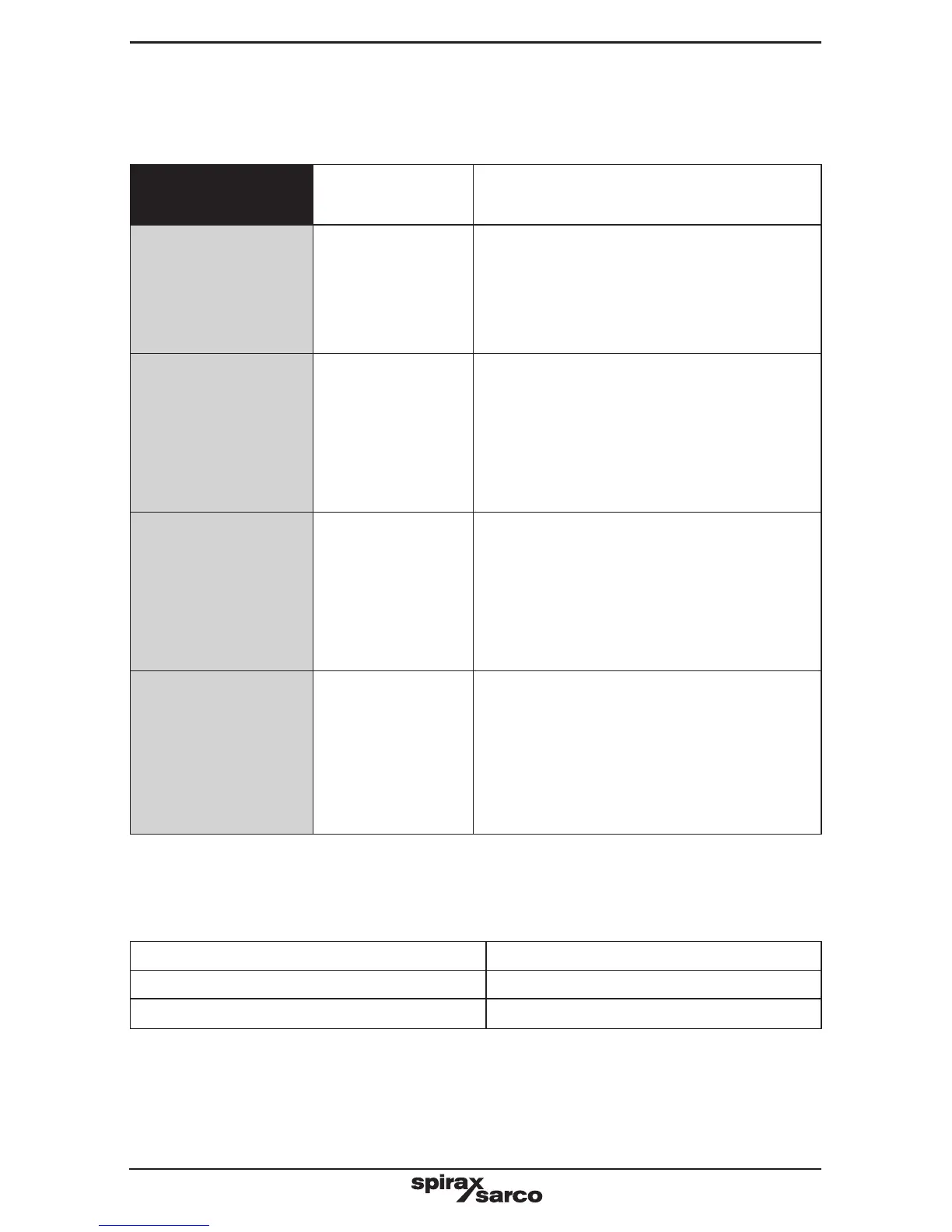

9.3 Operational error messages

Any operational errors that occur will be displayed in the run mode, on the alarms and

errors screen.

Error

message

Cause Action

1

Power out

There has been a

loss of power to

the product during

operation.

1. Remove the power from the product.

2. Check that all the wiring is correct.

3. Check that the power supply is secure,

i.e. does not suffer from 'brown outs'.

4. Reapply power.

2

Setup menu

time out

The operator

has entered the

commissioning

mode and has

not pressed a key

for 5 minutes or

more.

3. Re-enter the commissioning mode if

required.

3

Alarm 1

A high TDS alarm

has occurred.

1. Check the boiler operation. and the

alarm level setting.

The feedwater quality and treatment

regime should be checked as soon as

possible. Spirax Sarco offer boiler

water treatment advice and service.

4

Alarm is

latched!

Some errors latch

the alarm relay for

safety. Clearing

the error from

the error screen

just removes the

message.

1. Enter the commissioning (setup) mode.

If the correct password is entered all

the latched alarms will be cleared.

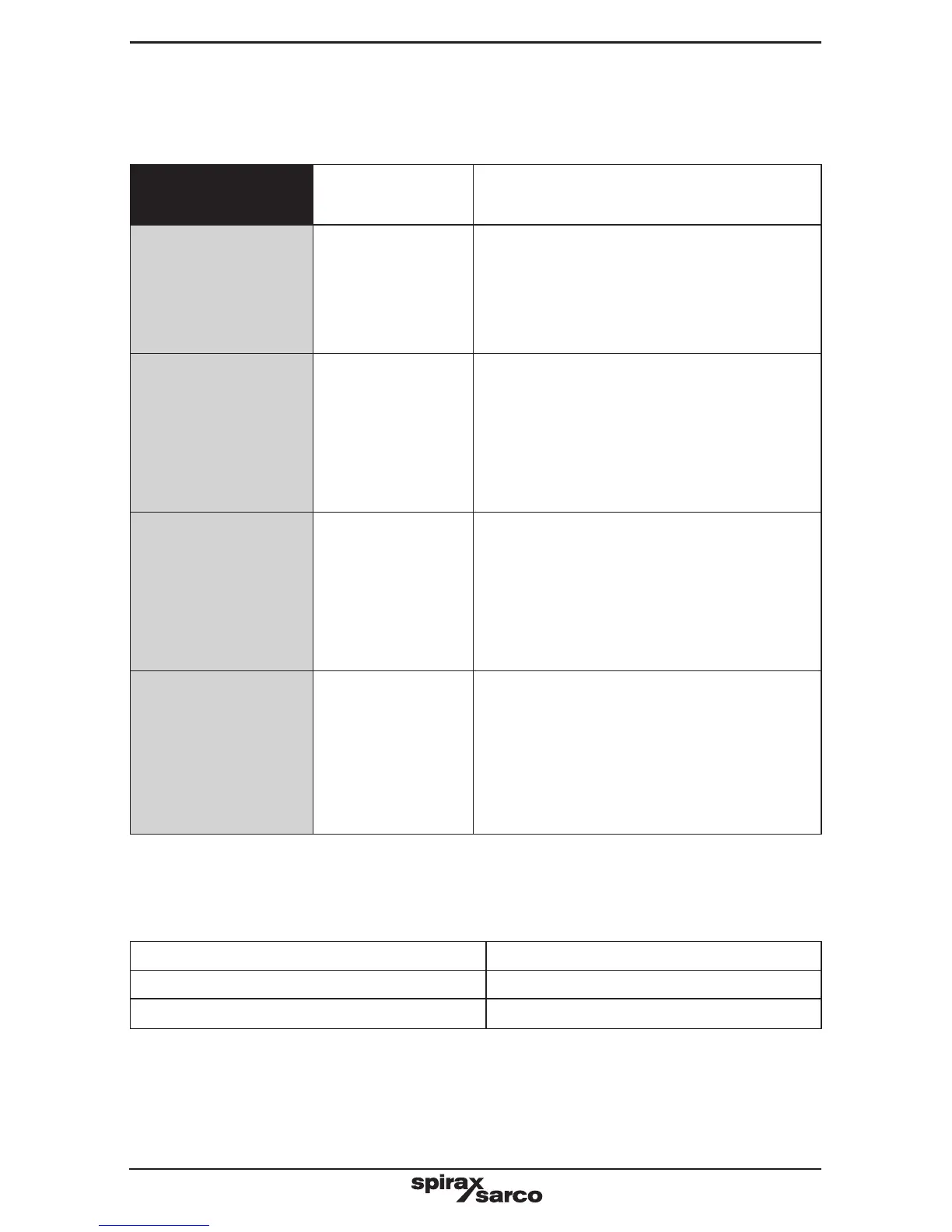

9.4 Determining the probe condition

The probe condition can be checked without removing it from the boiler.

From the run menu select probe factor (PF) and compare it with the following table:

Probe factors Typical

BCS1, BCS2, and BCS4 0.2 – 0.6

BCS3 0.3 – 0.7

A low cell constant indicates that the probe is able to conduct well, whereas a high cell constant

indicates that the probe tip has become less conductive, perhaps due to a build-up of scale.

A very low cell constant, however, could indicate an internal short circuit. The further the probe

tips from any part of the boiler, the higher the cell constant.

Loading...

Loading...