IM-P343-44 CTLS Issue 522

EP500 Standard Electropneumatic Positioner

5.1 Regular maintenance

1. Drain any build-up within the air supply lter set as impurities such as oil, water and dirt will

cause inconsistent operation.

2. Ensure air supply is at the correct pressure (see Section 3.3.2 and refer to the actuator TI).

3. Make visual checks to ensure that the valve is operating correctly.

5.2 Corrective maintenance

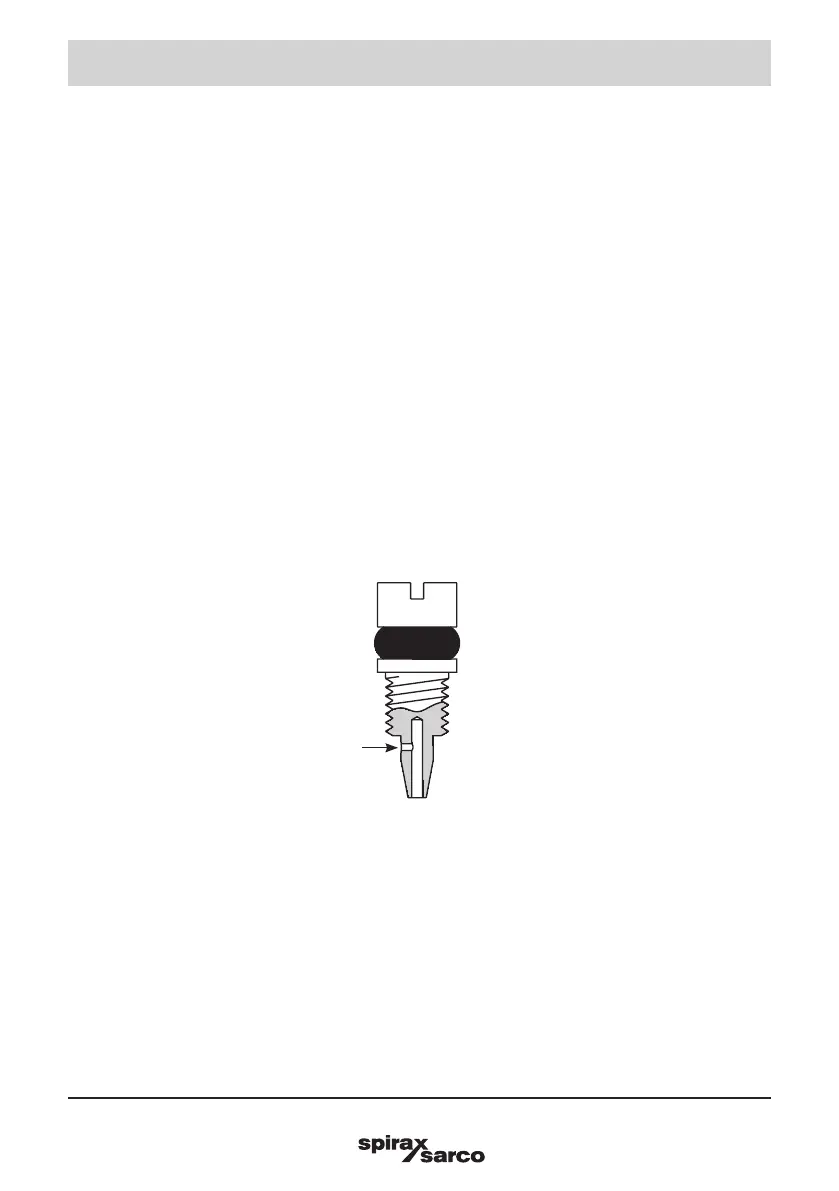

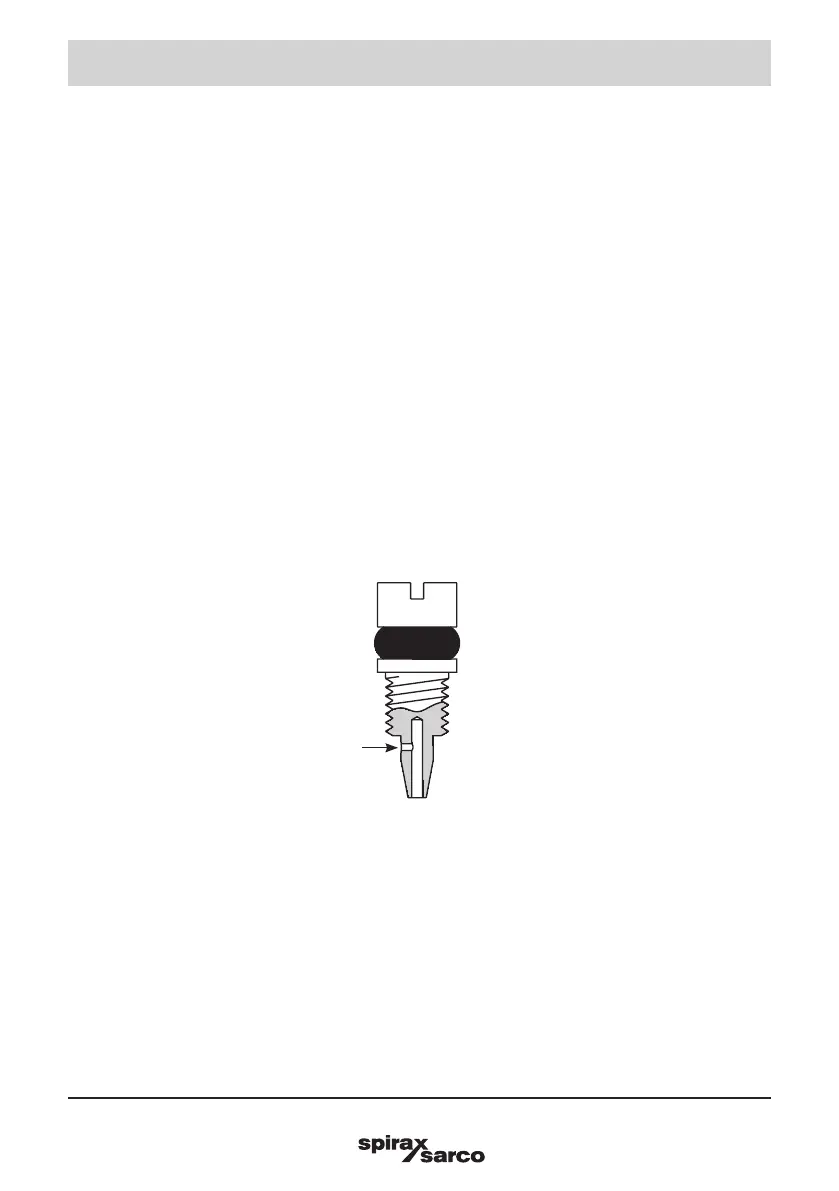

5.2.1 Removal and cleaning of sensitivity adjuster (see Figure 22):

-

Loosen and remove the lock.

-

Note setting then remove the sensitivity screw.

-

Wash the adjuster with solvent, checking the condition of the cone and ensuring that the

hole is clear.

-

Dry with clean compressed air to ensure that there is no remaining contaminants.

-

Ret the the cleaned adjuster and unscrew it ¼ turn from its stop.

Fig. 22

-

Ret the lock to touch the adjuster top and secure it with the lock-nut.

-

Set the sensitivity see Step 2, Section 4, Commissioning.

-

Reset zero and span if required.

Ensure that the side hole is clear

5. Maintenance

Loading...

Loading...