31

SRAM P5 CARGO

ASSEMBLY

Technical Manual 2006

Advice:

• If a different protective bracket (1, Fig. 5)

is used the thickness of the attachment

plate must be max. 3 mm.

• Do not use additional washers.

• At least the beginning of the axle thread

must be visible in front of the axle nut.

Caution:

Check that all the brake system

components are functioning properly!

ASSEMBLY SHIFTER

Advice:

• When choosing cable housing lengths,

be sure to allow enough housing for an

extreme turn of the handlebars in both

directions.

• Note also, that different stem lengths

and handlebar positions effects cable

housing length.

• Slide shifter (1, Fig. 6) onto handlebar.

• Mount fixed grip (2) onto end of handlebar.

• Slide shifter against fixed grip, adjust

shifter on handlebar and tighten with

bolt (3) with a torque of 1.5 Nm (13 in.lbs.).

Caution:

• Never use lubricants or solvents to

install fixed grips.

Fixed grips provide an axial safety

function. For this reason, they should be

mounted in such a way as to make sure

they do not slip off handlebar.

• Check that the shifter and brake lever

function properly and are unobstructed

(realign if necessary).

• Never ride without the fixed grips. The

turning grip may loosen from housing

and slip off handlebar – this can result

in severe injury or death.

• When fitting the cable avoid small radius.

Attach the cable 3 times to the down

tube (1, Fig. 7).

• Last attachment point is on the lower

rear wheel fork (2, Fig. 7) immediately

behind the chain wheel.

Cable housing must be movable inside

attachment.

INSTALLING CLICKBOX

• Insert shift rod (1, Fig. 8) in shift tube (2)

(oil parts lightly) and then push into axle

bore as far as the stop. If the shifting rod

is sticking up out of the axle end: apply

slight pressure on the shift rod with its

threaded section and screw inwards in

a clockwise direction until it can again

be moved axially (valid for older hub

versions). Turn slot (6) in shift tube to a

position where it is easily visible.

• Push locating sleeve (3) with guiding rib

(4) to the front onto the hub axle – making

sure that the internal lug (5) is guided in

the slot (6) of the shift tube until it can be

felt – and heard – to engage.

• Turn locating sleeve on the axle until the

guiding rib (4) is facing roughly upwards.

• Place shifter in gear position “2“.

• Push on Clickbox (2, Fig. 5) to the stop on

the hub axle. The guiding rib (4, Fig. 8) of

the locating sleeve thereby engages in

the slot on the housing. In the end position

tighten up the knurled bolt (3, Fig. 5) by

hand (0.3 Nm / 2.7 in.lbs.).

ADJUSTMENT

• Be sure to reset rotational shifter from

4th to 3rd gear.

• Match up the marks in the Clickbox

viewing window (4, Fig. 6) by turning

the adjusting screw (5).

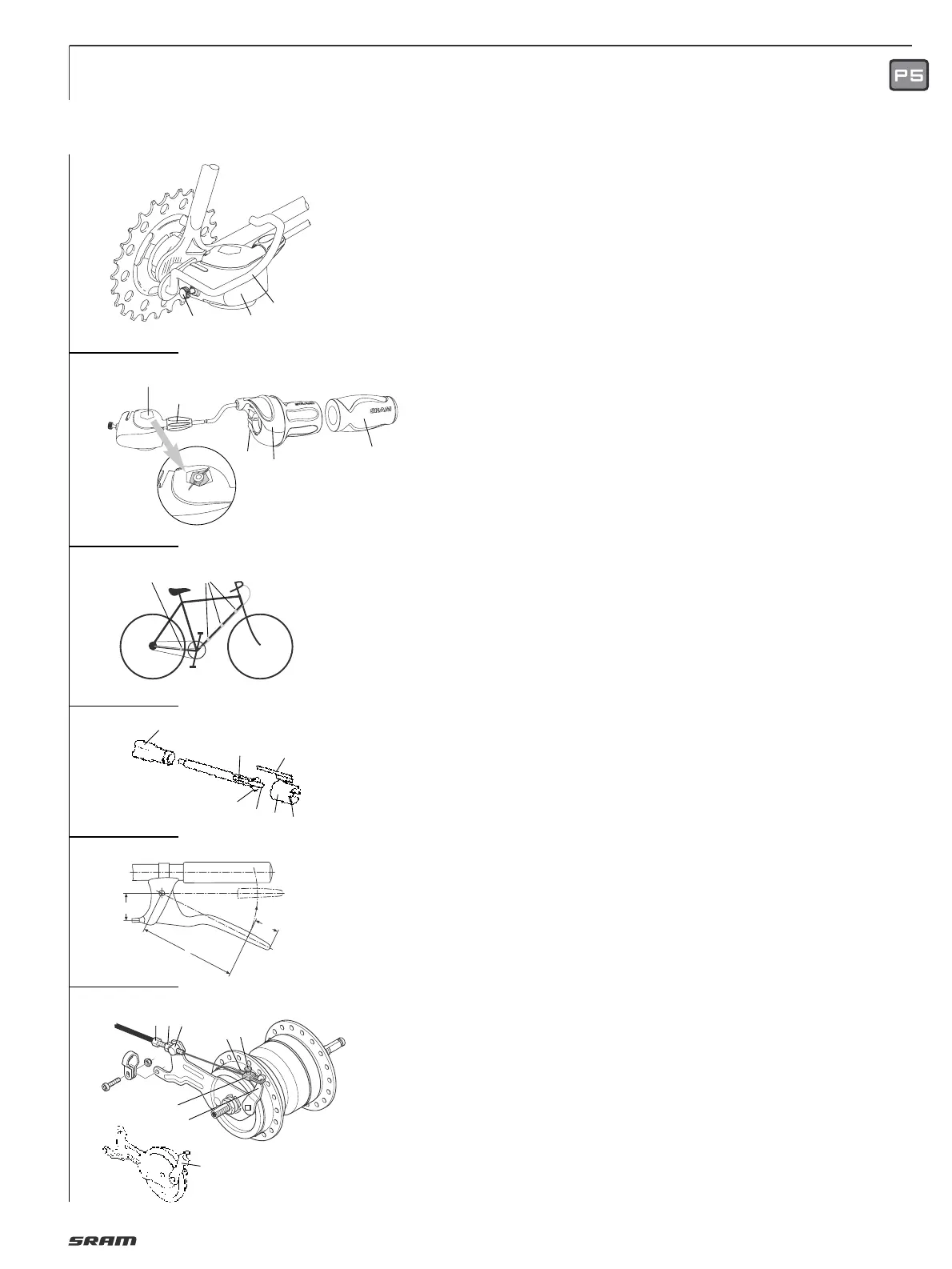

CONNECTING DRUM BRAKE

Caution:

Only use brake levers with a cable

moving distance of at least 15 mm and a

leverage of “i“ = 3.8 – 4.2 (Fig. 9).

• Fit cable stop (1, Fig. 10) with adjusting

bolt (2) and nut (3) and insert into the slot

on the brake anchor plate.

• Turn adjusting bolt down by approx.

2

/

3

and route the brake cable from the

brake handle.

• Push lower brake cable end through

adjusting bolt (2) and insert lower cable

housing end into adjusting bolt.

• Thread brake cable end (4) into

fork unit (5).

• Tighten screw (6) slightly.

• Attach fork unit to brake lever (7).

• Pull brake cable end taut with pliers

so that fork unit can still be attached and

removed (important for changing wheel).

• Tighten screw (6).

Caution:

For NL version drum brake hub with

special lever (8), only use original NL

brake cable (fork unit (5) is not suitable).

ADJUSTMENT DRUM BRAKE

• Unscrew adjusting screw (2, Fig. 10)

until the brake pads drag lightly.

• Actuate the hand brake lever forcefully

several times and then, if necessary,

turn the adjusting screw further in just

until the wheel starts spinning freely.

• Lock hex nut (3).

Caution:

Check that all the brake system

components are functioning properly!

CARGO

CARGO

7

5

6

8

9

3

2

1

8

5

7

6

4

132

10

a

i =

l

—

a

25

l

7

6

4

5

2

1

3

1

2

1

4

5

2

3

Loading...

Loading...