2. Specication

The ProSert® XTN20 hydro-pneumatic tool is designed for placing STANLEY Engineered Fastening Blind Rivet

Nuts through adjustment of the force and/or the stroke.

The ProSert® XTN20 Tool is used to place Blind Rivet Nuts from a range of M3 to M10 when coupled with the relevant

nose equipment. Imperial nose equipment is also available to place UNC and UNF inch thread size Blind Rivet Nuts.

The safety instructions must be followed at all times.

DO NOT use under wet conditions or in the presence of ammable liquids or gases.

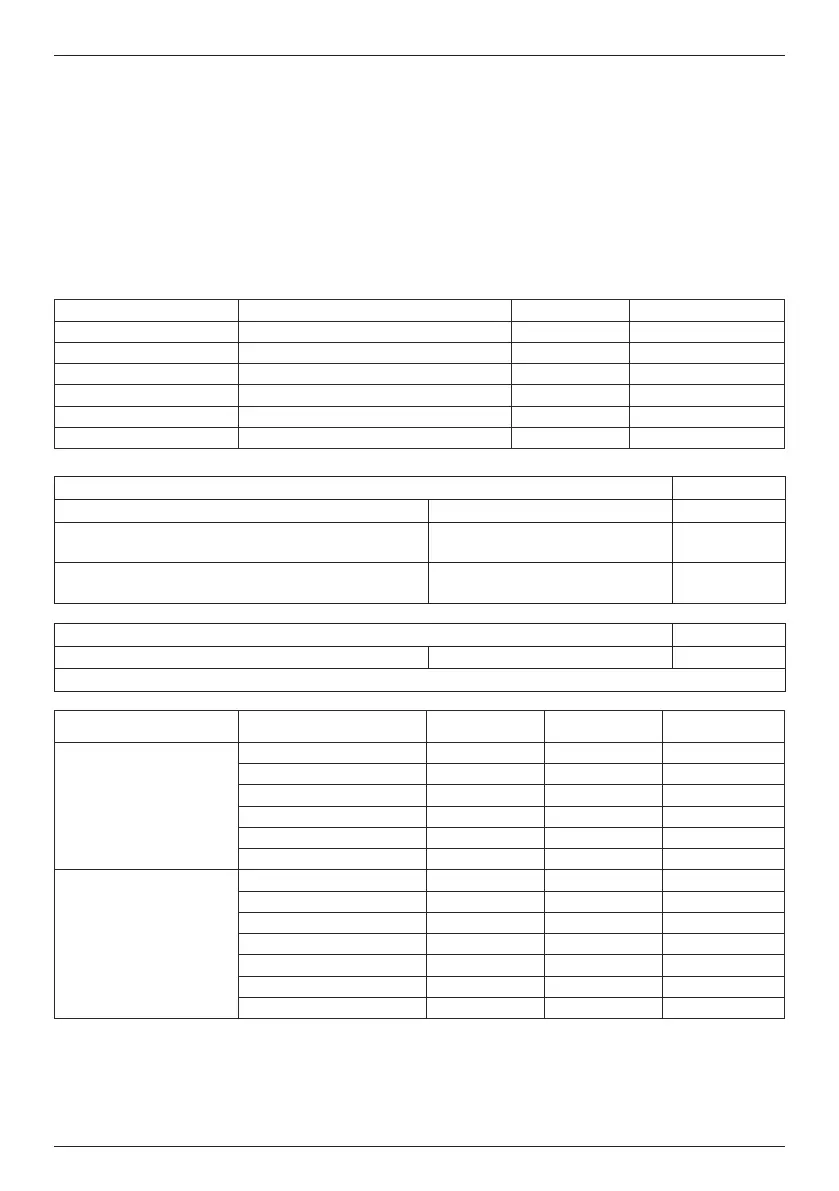

2.1. Placing Tool Specication

Pull Force: Pull @ stated pull pressure 5.0 Bar 17.65kN 3968 lbf

Air Supply Pressure Min/Max 5-7 Bar 72.5-101.5 lbf/in

²

Oil Pressure Pull (max) 230 Bar 3336 lbf/in

²

Free Air Volume: Max @ 5.5 Bar 4 L 244 in

3

Stroke: Piston stroke 3-7 mm 0.118-0.275 in

Weight: Including nose equipment 1.59 kg 3.50 lb

Motor Speed: Forward & Reverse 2000 rpm 2000 rpm

Noise values determined according to noise test code ISO 15744 and ISO 3744 XTN20

A-weighted sound power level dB(A), L

WA

Uncertainty noise: k

WA

= 3.0 dB(A) 74.2 dB(A)

A-weighted emission sound pressure level at the work

station dB(A), L

pA

Uncertainty noise: k

pA

= 3.0 dB(A) 63.2 dB(A)

C-weighted peak emission sound pressure level dB(C),

L

pC

,peak

Uncertainty noise: k

pC

= 3.0 dB(C) 106.4 dB(C)

Vibration values determined according to vibration test code ISO 20643 and ISOISO 5349 XTN20

Vibration emission level, ahd: Uncertainty vibration: k = 0.17 m/s

2

0.34 m/s

2

Declared vibration emission values in accordance with EN 12096

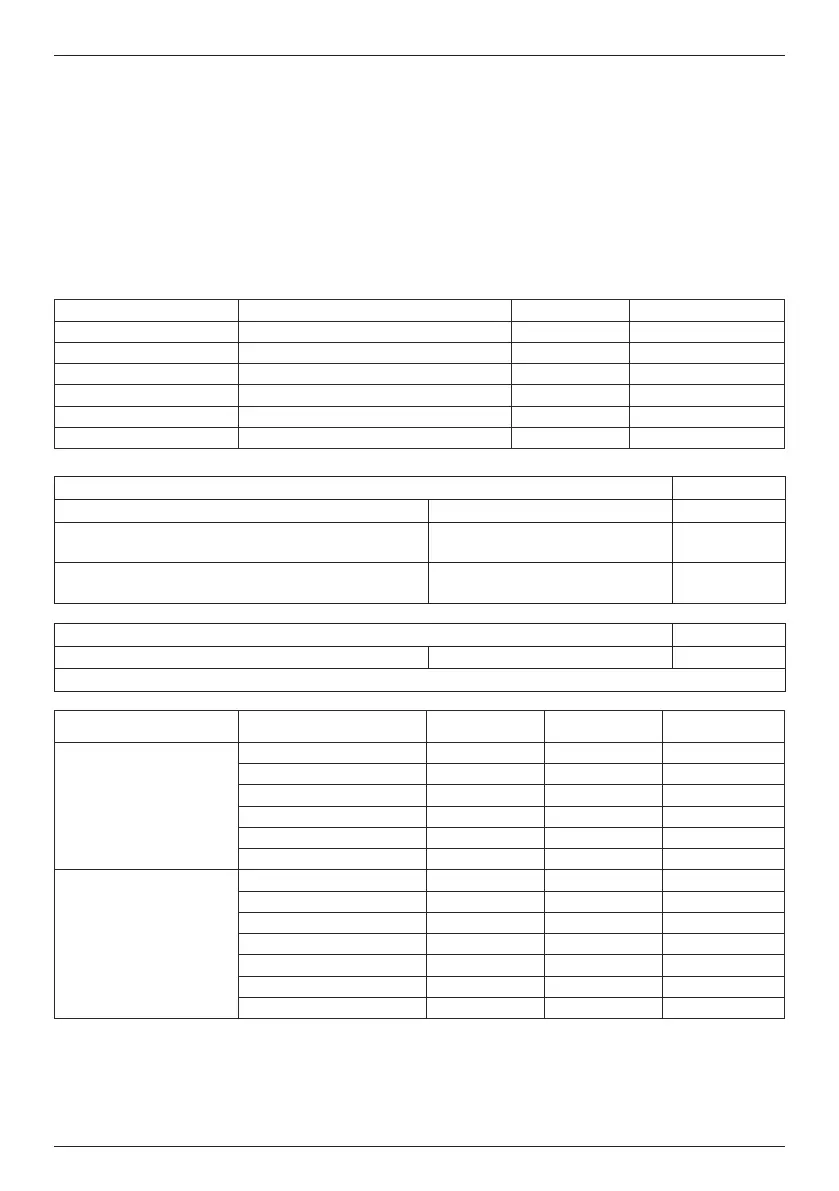

Material: - Aluminium Steel Stainless Steel

Avdel® Product Range:

Eurosert® - M3-M10 M4-M5

Thin Sheet Nutsert® M3-M10 M3-M10 M3-M10

DK/DL M4-M6 M4-M6 -

Euro Hexsert®/Hexsert® - M3-M8 M6

High Strength Hexsert® - M6-M8 -

Squaresert® - M5-M8 -

POP Nut®

Product Range:

Standard Nut* M3-M10 M3-M8 M4-M6

Knurled Nut* M4-M8 M4-M6 -

Closed End Nut* M3-M10 M3-M8 M4-M6

Hexagonal Nut* M4-M8 M4-M8 M4-M6

Tetra Nut* M4-M8 M4-M8 -

HB Bolt* M6-M8 M6-M8 -

Pipe Nut* M6 M6 -

9

ENGLISH

Loading...

Loading...