6932200010

23

Disconnect primary power at the source before

disassembling of torch leads.

Frequently review the important safety precautions

at the front of this Manual. Be sure the operator is

equipped with proper gloves, clothing, eye and ear

protection. Make sure no part of the operator’s

body comes into contact with the work-piece while

the torch is active.

CAUTION

Sparks from the cutting process can cause

damage to coated, painted, and other surfaces

such as glass, plastic and metal.

GENERAL TORCH MAINTENANCE

- A. Cleaning Torch

Even when precautions are taken to use only clean

air with a torch, eventually the inside of the torch

becomes coated with residue. This build-up can

affect the pilot arc initiation and the overall cut

quality of the torch.

WARNING.

ALWAYS DISCONNECT INPUT PRIMARY

SUPPLY!!!

Disconnect primary power to the system before

disassembling the torch or torch leads.

DO NOT touch any internal torch parts while the

AC indicator light of the power supply is ON.

The inside of the torch should be cleaned with

electrical contact cleaner using a cotton swab or

soft wet rag. In severe cases, the torch can be

removed from the leads and cleaned more

thoroughly by pouring electrical contact cleaner

into the torch and blowing it through with

compressed air.

CAUTION

Dry the torch thoroughly before reinstalling.

COMMON OPERATING FAULTS

The following lists the more common cutting faults

and possible causes:

1. Insufficient penetration

a. Cutting speed too fast

b. Torch not at 90°

c. Metal too thick

d. Worn torch parts

e. Cutting current too low

f. NON- genuine manufacturer parts

2. Cutting Arc Extinguishes

a. Cutting speeds too slow

b. Torch stand-off too high from work piece

c. Cutting current too high

d. Work cable disconnected

e. Worn torch parts

f. NON- genuine manufacturer parts

3. Excessive dross Formation

a. Cutting speeds too slow

b. Torch stand-off too high from work piece

c. Worn torch parts

d. Improper cutting current

e. NON- genuine manufacturer parts

4. Short Life of Torch parts

a. Oil or moisture in air source

b. Exceeding system capability (material too thick)

c. Excessive pilot arc time

d. Air flow too low (incorrect air pressure)

e. Improperly assembled torch

f. NON- genuine manufacturer parts

INSPECTION AND REPLACEMENT

CONSUMABLE TORCH PARTS

WARNING:

ALWAYS DISCONNECT INPUT PRIMARY

SUPPLY!!!

Disconnect primary power to the system before

disassembling the torch or torch leads

DO NOT touch any internal torch parts while the

AC indicator light of the power supply is ON.

Remove the consumable torch parts as follows

NOTE

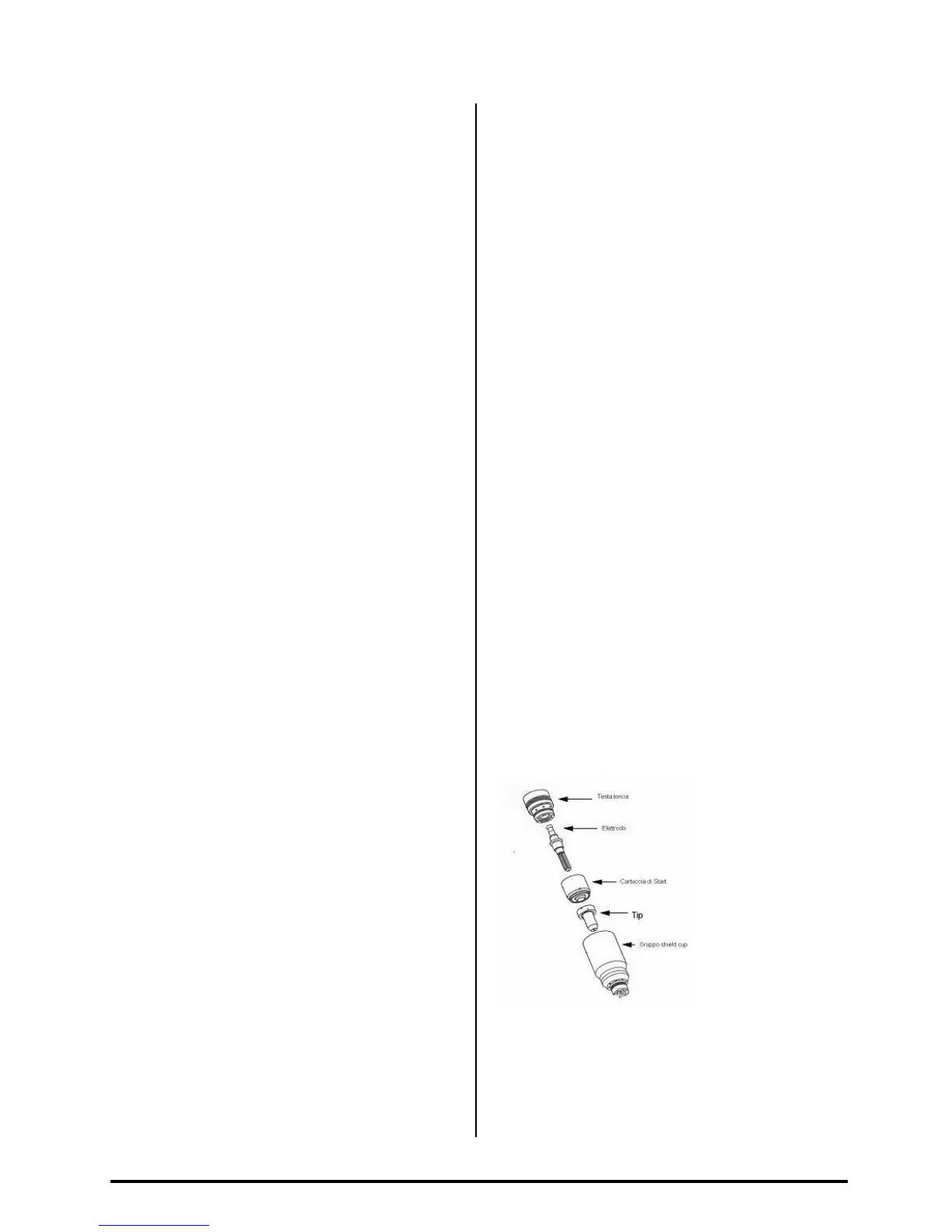

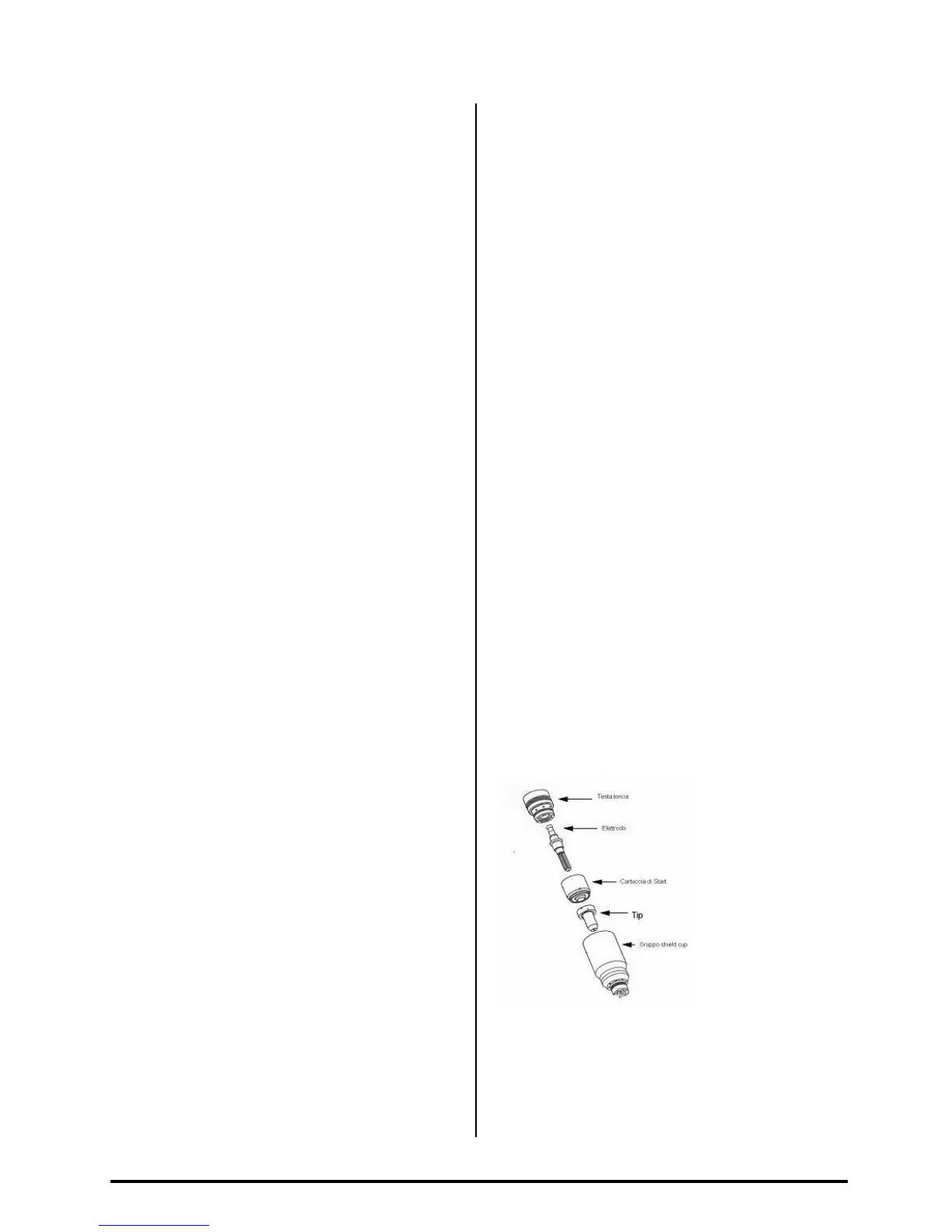

The shield cup holds the tip and the starter

cartridge shield cup in place. Position the torch

with the shield cup facing out when the cup is

removed.

1. Unscrew and remove the shield cup from the

torch

NOTE

Slag build-up on the shield cup that cannot be

removed may effect the performance of the

system.

2. Inspect the cup for damage. Wipe it clean or

replace if damaged

Consumables parts

3. Removed the tip. Check for excessive wear

(indicated by an elongated or oversize

orifice).Clean or replace the tip if necessary.

Loading...

Loading...